Preparation method of NiMoP electrode for hydrogen evolution by alkaline electrolysis of water

A technology of electrolysis of water and hydrogen evolution, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of toxicity, flammability, and unsuitability for industrial production, and achieve high HER activity, good uniformity, and the effect of inhibiting electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

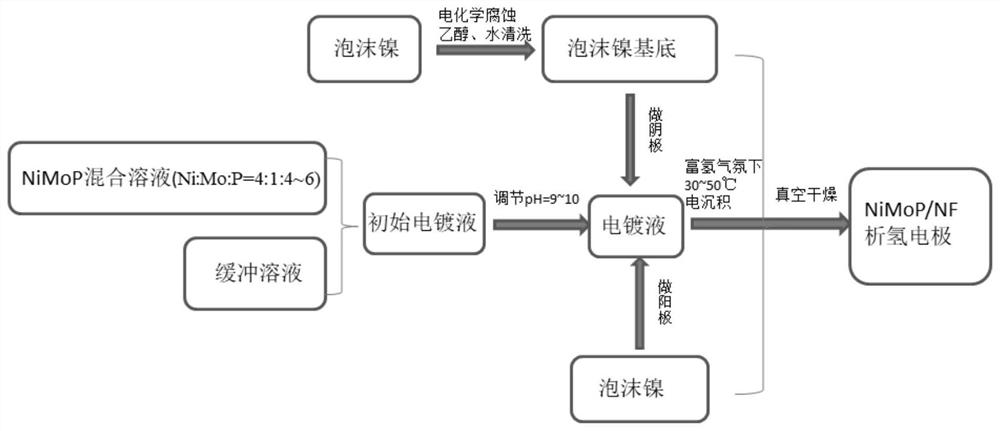

[0039] A preparation method for a NiMoP electrode for hydrogen evolution in alkaline electrolysis of water, comprising the following steps:

[0040] (1) Foam nickel (NF) is placed in 25wt% sulfuric acid solution, at 5mA / cm 2 Electrochemical corrosion was carried out for 5 minutes under the current density to obtain foamed nickel after electrochemical corrosion.

[0041] (2) NiMoP mixed solution was prepared by using ammonium molybdate, nickel sulfate and sodium hypophosphite. The concentration of ammonium molybdate in the mixed solution was 0.07M (mol / L), the concentration of nickel sulfate was 0.28M, and the concentration of sodium hypophosphite was 0.28 M. Then sodium citrate was added to the mixed solution, and the pH of the solution was adjusted to 9 with 6M NaOH to obtain an electroplating solution. The concentration of sodium citrate in the plating solution is 0.3M.

[0042] (3) Move the electroplating solution prepared in step (2) into the electroplating tank, flow a...

Embodiment 2

[0045] A preparation method for a NiMoP electrode for hydrogen evolution in alkaline electrolysis of water, comprising the following steps:

[0046] (1) Foam nickel is placed in 25wt% sulfuric acid solution, at 5mA / cm 2 Electrochemical corrosion was carried out for 5 minutes under the current density to obtain foamed nickel after electrochemical corrosion.

[0047](2) NiMoP mixed solution was prepared by using ammonium molybdate, nickel sulfate and sodium hypophosphite. The concentration of ammonium molybdate in the mixed solution was 0.07M, the concentration of nickel sulfate was 0.28M, and the concentration of sodium hypophosphite was 0.28M. Boric acid and ammonium chloride are added to the mixed solution, and the pH of the solution is adjusted to 9 with ammonia water to obtain an electroplating solution. The concentration of boric acid in the electroplating solution is 0.4M, and the concentration of ammonium chloride is 0.3M.

[0048] (3) Move the electroplating solution ...

Embodiment 3

[0051] A preparation method for a NiMoP electrode for hydrogen evolution in alkaline electrolysis of water, comprising the following steps:

[0052] (1) Foam nickel is placed in 25wt% sulfuric acid solution, at 5mA / cm 2 Electrochemical corrosion was carried out for 5 minutes under the current density to obtain foamed nickel after electrochemical corrosion.

[0053] (2) Prepare a NiMoP mixed solution by using 0.07M ammonium molybdate, 0.28M nickel sulfate and 0.28M sodium hypophosphite, then add 0.4M sodium acetate to the solution, and adjust the pH to 10 with ammonia water to obtain an electroplating solution.

[0054] (3) Move the electroplating solution prepared in step (2) to the electroplating tank, flow a hydrogen-rich atmosphere at the bottom, and use foamed nickel as the anode at 40°C, and the foamed nickel after electrochemical corrosion in step (1) as the cathode Conduct electrodeposition with a current density of 0.1A / cm 2 , The electrodeposition time is 70min.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com