Method for preparing thorium oxide by utilizing monazite excellent molten slag

A technology of thorium oxide and slag melting, which is applied in the field of preparing thorium oxide by using excellent slag of monazite, can solve the problems of multiple extractions, and achieve the effects of reducing extraction links, no environmental pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Raw material components

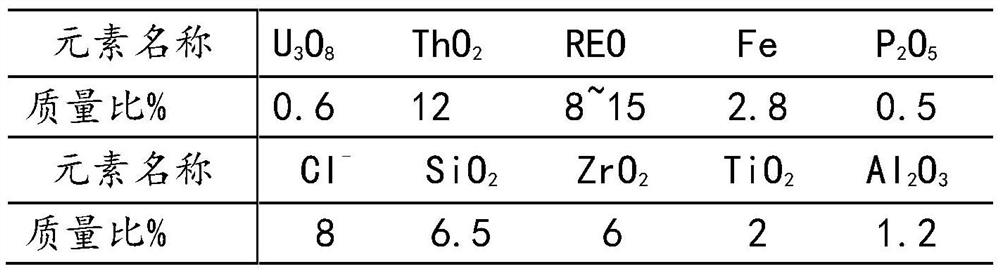

[0045] The typical values of the main components of monazite excellent molten slag are shown in the following table: the water content of wet base analysis is 40%, and its main chemical components are shown in Table 1.

[0046]

[0047] Table 1 The main chemical components of monazite excellent molten slag

[0048] 2. Preparation

[0049] (1) Pretreatment: Take 1000Kg of monazite excellent molten slag of the above ingredients and pour it into a 5m3 PP tank with stirring, add water to adjust the solid content to 20%, use a 6-S fine sand shaker, stroke 15mm, stroke times 300 times / min, the transverse inclination angle is 2.6°, the longitudinal inclination angle is 0.6°, the ore feeding concentration is 20%, and the ore feeding rate is 0.1T / min. Select heavy sand, the main components of heavy sand are (slag rate ~ 25%): moisture ~ 10%, monazite and xenotime ~ 25%, zircon ~ 50%, rutile ~ 3%, etc., return to monazite Concentrate alkali b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com