Special modified asphalt suitable for tropical asphalt pavement and preparation method thereof

A technology for modifying asphalt and asphalt pavement, which is applied to building components, building insulation materials, buildings, etc., to achieve good economic benefits, improve rutting resistance, and increase viscosity, toughness, and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing special modified asphalt suitable for tropical asphalt pavement, comprising the steps of:

[0038] S1, each component is weighed according to the weight part;

[0039] S2. Heating the base asphalt to a fluid state, stirring and preheating to 170-185° C., adding a polymer elastomer modifier, and shearing for 1 hour to obtain a premix.

[0040] S3, adding the rubber oil to the premix, stirring for 0.5h;

[0041] S4. Add antioxidant, stir for 0.5h, add stabilizer, lower the temperature of modified asphalt to 175°C±5°C and stir for 4-5h.

[0042] S5. Cool down to 150° C., add special curing agent, special asphalt granules, viscosity reducer and plastic granules, and stir for 4 hours to obtain the sample A.

[0043] S6. Add bisphenol A and non-bisphenol A epoxy resin to sample A before processing the mixture or before testing, and stir evenly to prepare special modified asphalt for tropical asphalt pavement.

[00...

Embodiment 1

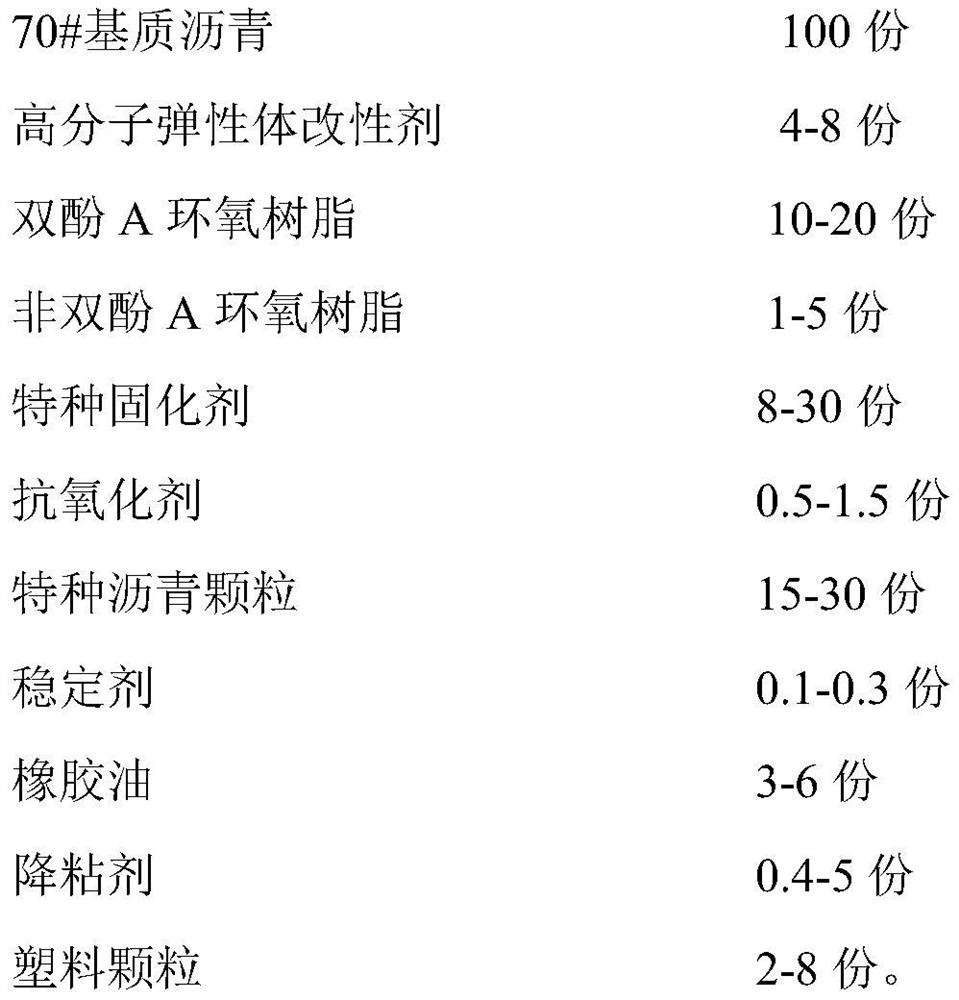

[0050] Raw material ratio:

[0051]

[0052]

[0053] Modified asphalt preparation:

[0054] S1, each component is weighed according to the weight part;

[0055] S2. Heating the Taizhou CNOOC 70# bitumen to a flow state, stirring and preheating to 170-185° C., adding SBR modifier, and shearing for 1 hour to obtain a premix.

[0056] S3. Add the No. 8-12 rubber oil to the premix, and stir for 0.5h;

[0057] S4. Add butylated hydroxytoluene (BHT), stir for 0.5h, add sulfur, lower the temperature of the modified asphalt to 175°C±5°C and stir for 4-5h.

[0058] S5. Cool down to 150° C., add octadecylamine, 30# asphalt, Honeywell 7686 and LLDPE, and stir for 4 hours to obtain the sample A.

[0059] S6. Add bisphenol A epoxy resin NPEL128 and EP-207 to sample A before processing the mixture or before testing, and stir evenly to prepare special modified asphalt for tropical asphalt pavement.

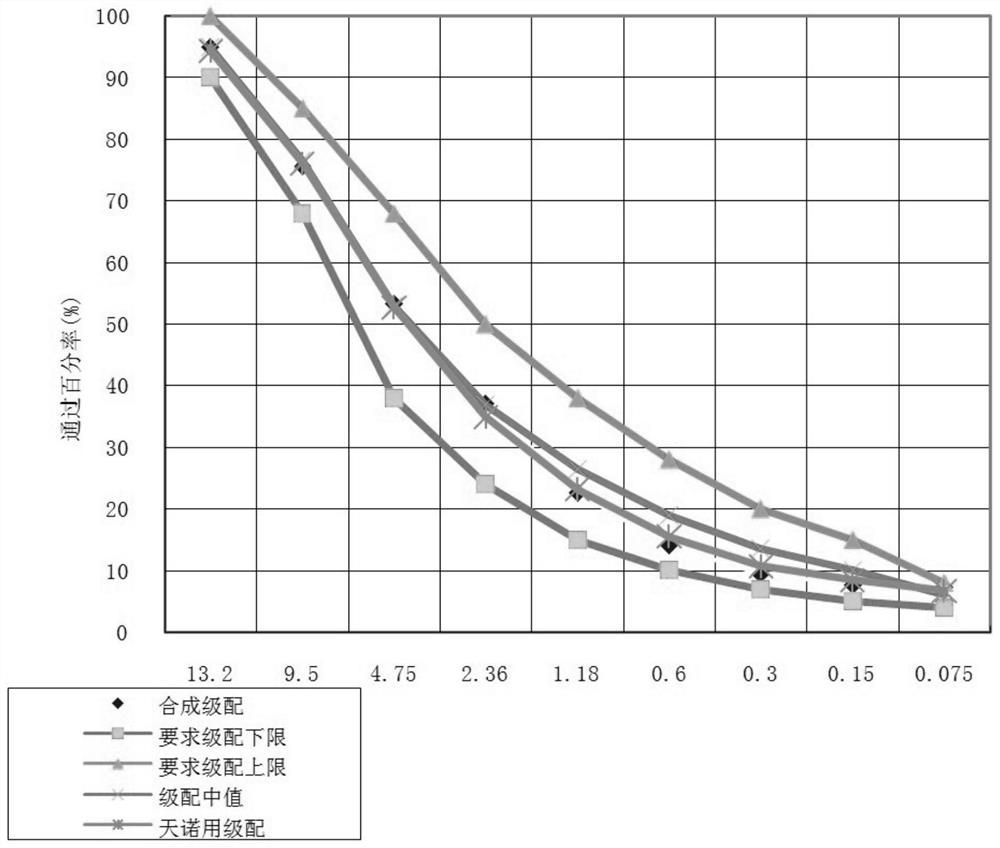

[0060] Preparation of AC-13 asphalt mixture:

[0061] Take 100 parts of the AC-1...

Embodiment 2

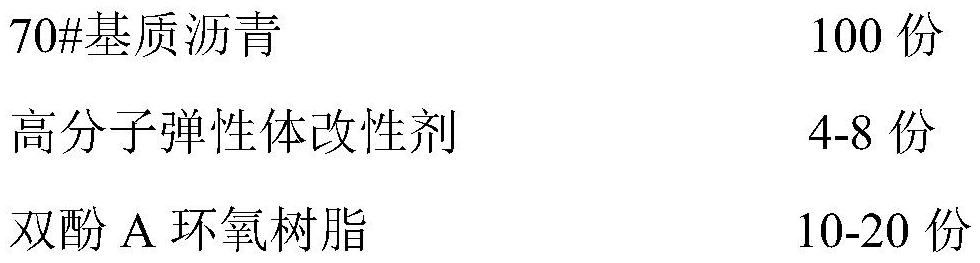

[0068] Raw material ratio:

[0069]

[0070]

[0071] Modified asphalt preparation:

[0072] S1, each component is weighed according to the weight part;

[0073] S2. Heating the Ssangyong 70# asphalt to a fluid state, stirring and preheating to 170-185°C, adding a linear SBS modifier, and shearing for 1 hour to obtain a premix.

[0074] S3. Add the No. 8-24 rubber oil to the premix, and stir for 0.5h;

[0075] S4. Add tert-butylhydroquinone (TBHQ), stir for 0.5h, add sulfur, lower the temperature of the modified asphalt to 175°C±5°C and stir for 4-5h.

[0076] S5. Cool down to 150°C and add special hexadecylamine, 20# asphalt, Sasobit and LDPE, and stir for 4 hours to obtain the sample A.

[0077] S6. Add bisphenol A epoxy resin E51 and ERL-4221 to sample A before processing the mixture or before testing, and stir evenly to prepare modified asphalt specially for tropical asphalt pavement.

[0078] Preparation of AC-13 asphalt mixture:

[0079] Take 100 parts of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com