Ruthenium-based metal ion liquid polymer microsphere artificial enzyme as well as preparation method and application thereof

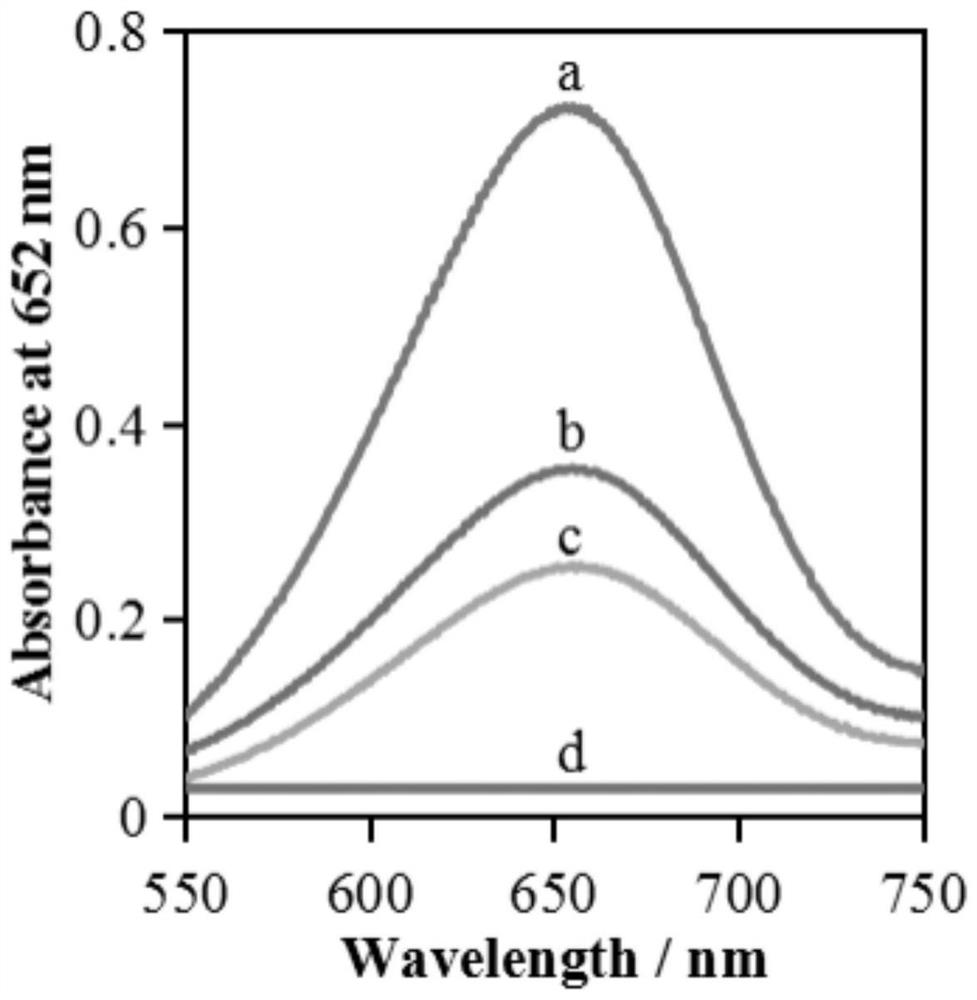

An ionic liquid and metal-based technology, which is applied in the field of ruthenium-based metal ionic liquid polymer microsphere artificial enzyme and its preparation, can solve the problem of low activity, achieve high catalytic activity, high oxidase-like activity, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

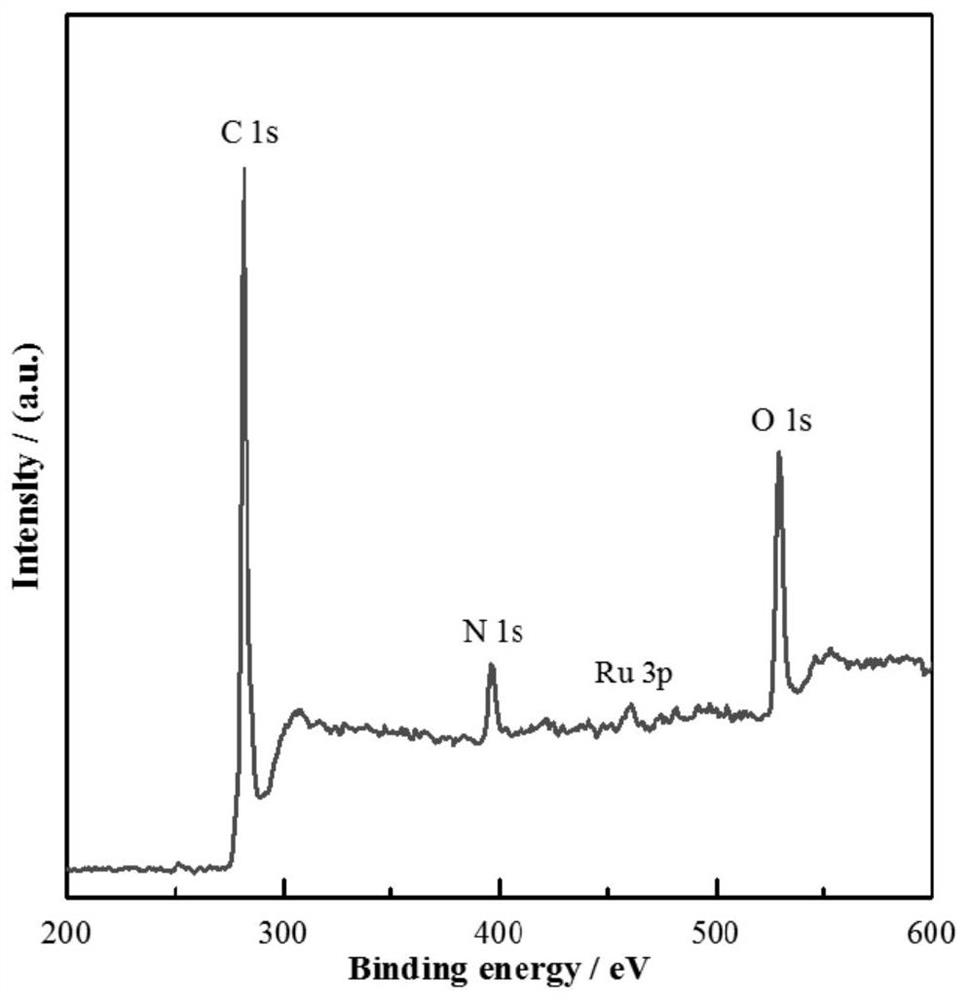

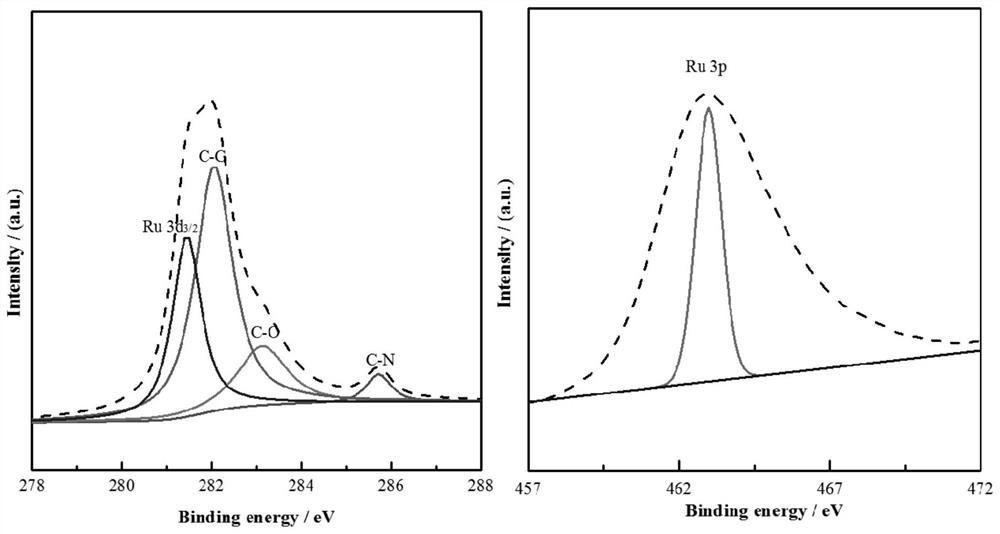

[0037] A kind of ruthenium-based metal ionic liquid polymer microsphere artificial enzyme, its preparation method comprises the steps:

[0038](1) Mix 60mL of salicylic acid (0.1mol / L), 60mL of vinylimidazole (0.1mol / L) and 10mL of ruthenium trichloride (0.1mol / L) in water, stir at 65°C for 60min at 60r / min , to obtain a black mixture. Then extract with dichloromethane, remove the solvent by rotary evaporation of the oil phase solution, the temperature of the rotary evaporation is 70°C, and the time is 1h to completely remove the solvent, and the resulting solution is vacuum-dried overnight at 75°C to obtain a black oily liquid that is ruthenium base Vinylimidazole Salicylate Ionic Liquid.

[0039] (2) Take 10g of ionic liquid and disperse it in 100mL of water, add 100g of divinylbenzene, and use a homogenizer to mix and homogenize. Based initiator, reflux reaction in a nitrogen atmosphere for 24h, the reaction temperature is 100°C, then filtered and washed 5 times with deio...

Embodiment 2

[0045] A kind of ruthenium-based metal ionic liquid polymer microsphere artificial enzyme, its preparation method comprises the steps:

[0046] (1) Mix 60mL of salicylic acid (1.2mol / L), 50mL of vinylimidazole (1.2mol / L) and 15mL of ruthenium trichloride (1.2mol / L) in water, stir at 65°C for 45min at 75r / min , to obtain a black mixture. Then extract with dichloromethane, remove the solvent by rotary evaporation of the oil phase solution, the temperature of the rotary evaporation is 70°C, and the time is 1h to completely remove the solvent, and the resulting solution is vacuum-dried at 70°C for 8h to obtain a black oily liquid that is ruthenium base Vinylimidazole Salicylate Ionic Liquid.

[0047] (2) Take 100g of ionic liquid and disperse it in 100mL of water, add 100g of divinylbenzene, and use a homogenizer to mix and homogenize. Based initiator, reflux reaction in a nitrogen atmosphere for 10h, the reaction temperature is 60°C, then filtered and rinsed with deionized wate...

Embodiment 3

[0050] A kind of ruthenium-based metal ionic liquid polymer microsphere artificial enzyme, its preparation method comprises the steps:

[0051] (1) Mix 60mL salicylic acid (0.05mol / L), 60mL vinylimidazole (0.05mol / L) and 10mL ruthenium trichloride (0.05mol / L) aqueous solution, stir at 65°C for 55min at 60r / min , to obtain a black mixture. Then extract with dichloromethane, remove the solvent by rotary evaporation of the oil phase solution, the temperature of the rotary evaporation is 70°C, and the time is 1h to completely remove the solvent, and the resulting solution is vacuum-dried at 100°C for 12h to obtain a black oily liquid that is ruthenium base Vinylimidazole Salicylate Ionic Liquid.

[0052] (2) Take 20g of ionic liquid and disperse it in 100mL of water, add 100g of divinylbenzene, use a homogenizer to mix and homogenize, the speed of homogenization is 900r / min, the time is 5min, after mixing evenly, add 0.066g of ammonium persulfate free Based initiator, reflux rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com