Aluminum-titanium composite cross-linking agent, preparation method and application thereof, and guar gum acidic fracturing fluid system

A composite cross-linking agent, aluminum-titanium technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as increased pipeline friction, poor temperature resistance of fracturing fluid, and short cross-linking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the aluminum-titanium composite crosslinking agent described in the above technical scheme, comprising the following steps:

[0033] Mix water, organic acid, triethanolamine and inorganic polymer aluminum salt for the first coordination reaction to obtain polymer aluminum coordination products;

[0034] Mix titanate and triethanolamine for a second coordination reaction to obtain a titanium coordination product;

[0035] The titanium coordination product, the polymer aluminum coordination product and acetic acid are mixed to obtain the aluminum-titanium composite crosslinking agent.

[0036] The invention mixes water, organic acid, triethanolamine and inorganic macromolecular aluminum salt to carry out the first coordination reaction to obtain a macromolecular aluminum coordination product.

[0037] The present invention preferably first mixes the inorganic polymer aluminum salt with water, then adds the triet...

Embodiment 1

[0052] (1) Place a 2500mL three-necked flask in a water bath at 50°C to keep the temperature constant, add 600g of water to the three-necked flask, weigh 100g of polyaluminum chloride and dissolve it in water, add 50g of triethanolamine under magnetic stirring conditions, and add 50g of it after 1 hour of reaction Lactic acid, continue to stir for 1 hour to obtain the polymer aluminum coordination product;

[0053](2) Place a 250mL three-neck flask in a water bath at 50°C to keep the temperature constant, add 30g of tetraisopropyl titanate and 30g of triethanolamine to the three-necked flask in turn, mix and stir for 2 hours to obtain a titanium coordination product;

[0054] (3) Add the product obtained in step (2) to the product obtained in step (1), then add 140 g of acetic acid, and mix evenly to obtain a high molecular weight aluminum-titanium composite crosslinking agent for guar gum acidic fracturing fluid system.

Embodiment 2

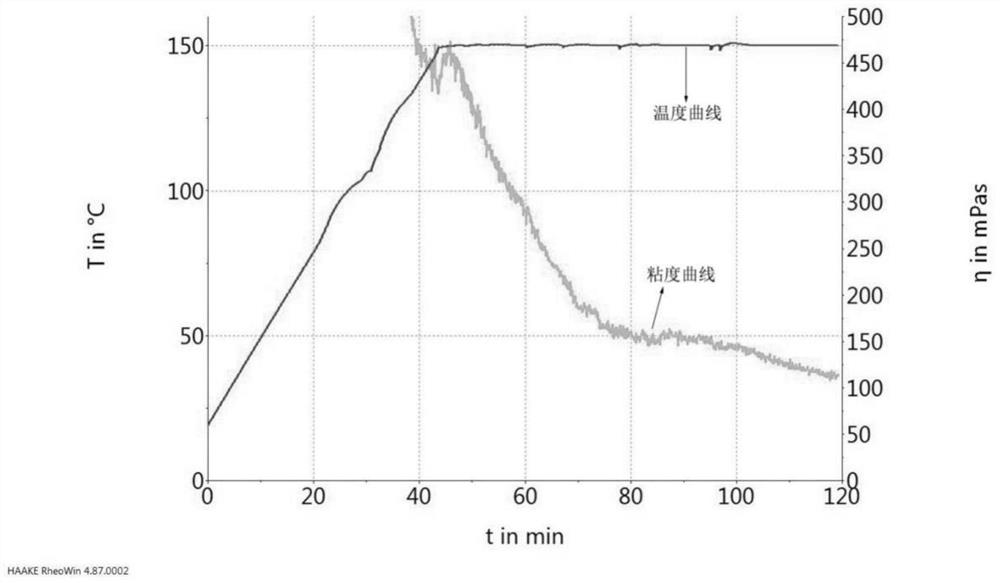

[0063] Prepare 100mL of 0.55wt% carboxymethyl hydroxypropyl guar gum base liquid, let it stand for 2h, add 0.4wt% aluminum-titanium composite crosslinking agent prepared in Example 1, 0.3wt% clay stabilizer, 0.3wt% drainage aid agent, the pH value of the prepared guar gum acidic fracturing fluid system is 4.5, and the gel crosslinking time is 200s. The cross-linking agent played the role of significantly delaying the cross-linking time.

PUM

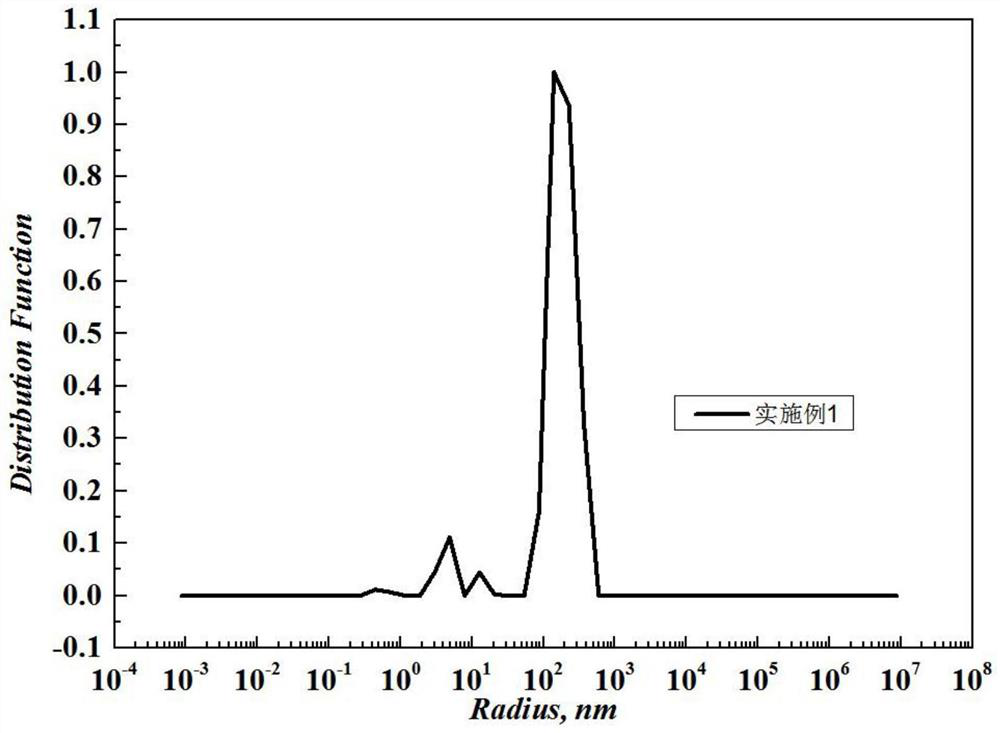

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com