Electrochemical synthesis method for preparing o-benzenedimethanol from phthalide

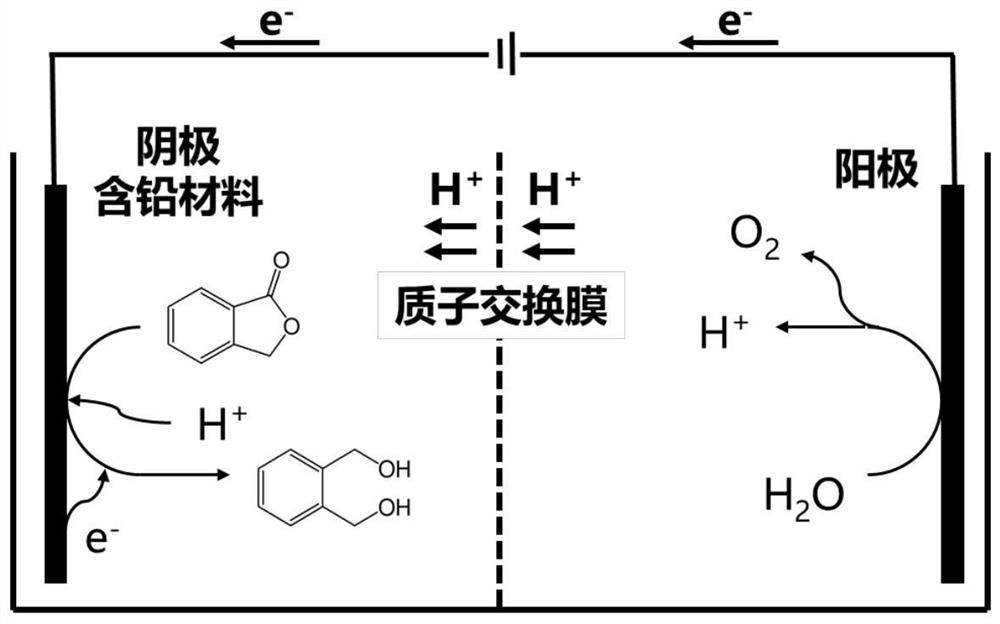

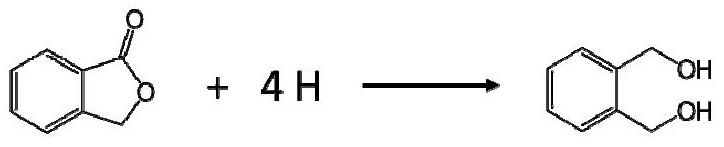

A technology of phthalic acid and a synthesis method, which is applied in electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of low product purity, complicated operation process, high production cost, avoid excessive hydrogenation, simple process, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Prepare 50mL electrolyte solution containing 0.2M sulfuric acid and 0.01M phthalic anhydride, mix well and add 50mL cathode chamber of H-type electrolytic cell with diaphragm, use the same 50mL electrolyte solution containing 0.2M sulfuric acid as the anode, and keep the water bath of the whole device at constant temperature to 30°C . Platinum was used as the anode material, lead was used as the cathode material, and a three-electrode system was used for electrolysis, and the electrolysis was performed at -1.4Vvs Ag / AgCl for 4 hours in constant voltage mode. After the electrolysis, the electrolytic solution was extracted three times with ethyl acetate, and the hydrogenation product of phthalide was analyzed by gas chromatography-mass spectrometry. The conversion rate of phthalide was 90%, and the selectivity of o-phthalein dimethanol was 89%.

Embodiment 2

[0020] Prepare 50mL electrolyte solution containing 0.1M sulfuric acid and 0.01M phthalic anhydride, mix well and add 50mL cathode chamber of H-type electrolytic cell with diaphragm, use the same 50mL electrolyte solution containing 0.1M sulfuric acid as the anode, and keep the temperature of the water bath of the whole device at 30°C . Platinum was used as the anode material, lead was used as the cathode material, and a three-electrode system was used for electrolysis, and the electrolysis was performed at -1.2Vvs Ag / AgCl for 6 hours in constant voltage mode. After electrolysis, the electrolytic solution was extracted three times with ethyl acetate, and the hydrogenation product of phthalide was analyzed by gas chromatography-mass spectrometry. The conversion rate of phthalide was 50%, and the selectivity of o-phthalein dimethanol was 58%.

Embodiment 3

[0022] Prepare 50mL electrolyte solution containing 0.2M sulfuric acid and 0.02M phthalic anhydride, mix well and add 50mL cathode chamber of H-type electrolytic cell with diaphragm, use the same 50mL electrolyte solution containing 0.2M sulfuric acid as the anode, and keep the temperature of the whole device in a water bath to 80°C . Copper foam was used as the anode material, lead was used as the cathode material, and a three-electrode system was used for electrolysis, and electrolysis was performed at -1.4V vs Ag / AgCl for 4h in constant voltage mode. After electrolysis, the electrolytic solution was extracted three times with ethyl acetate, and the hydrogenation product of phthalide was analyzed by gas chromatography-mass spectrometry. The conversion rate of phthalide was 62%, and the selectivity of o-phthalein dimethanol was 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com