Shell powder functional coating as well as preparation method and application thereof

A technology of functional coatings and shell powder, applied in fireproof coatings, coatings, etc., can solve the problems of low formaldehyde degradation efficiency and inability to catalyze degradation, achieve excellent visible light catalytic degradation performance, improve photocatalytic degradation efficiency, and efficiently remove formaldehyde Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

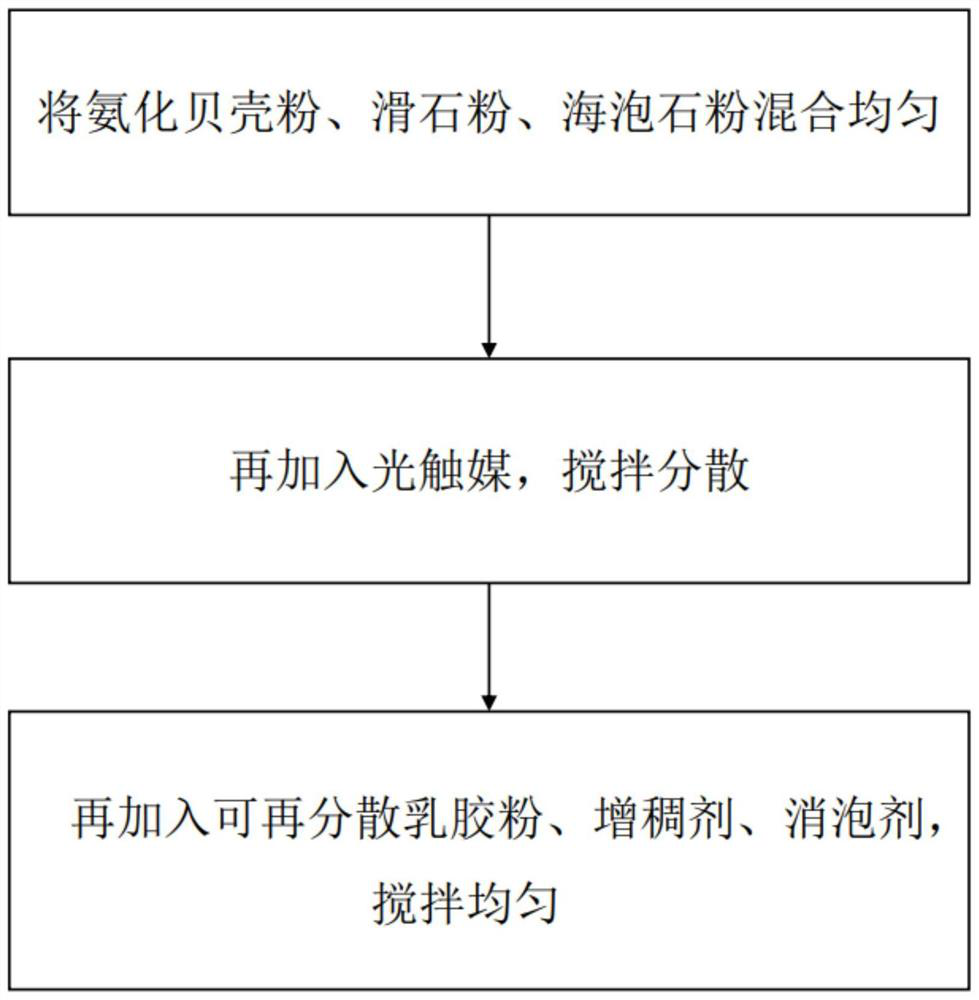

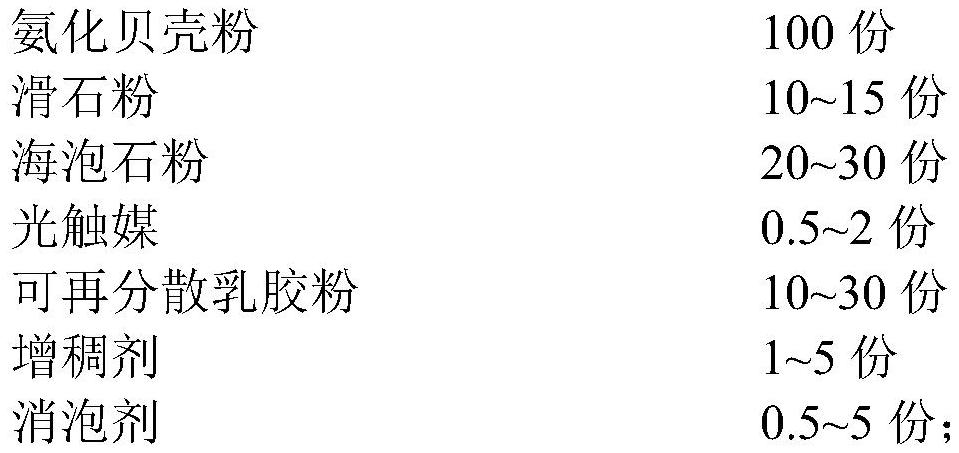

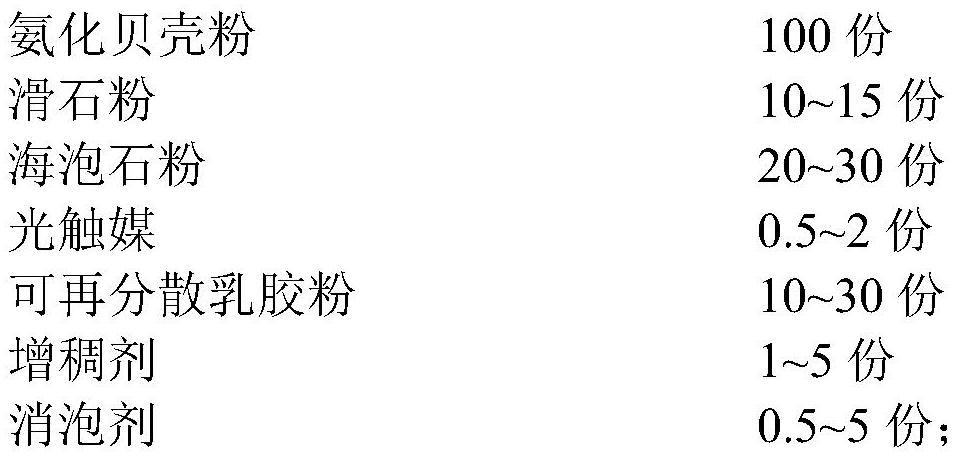

Method used

Image

Examples

Embodiment 1

[0031] S1: adding shell powder to acetic acid solution with a mass concentration of 10% and stirring for 10 minutes, filtering and calcining at 500°C for 6 hours to obtain digested shell powder; the mass ratio of shell powder to acetic acid solution is 1:5;

[0032] S2: Dissolve 10 parts of 4-amino-5-imidazole carboxamide and 5 parts of tetraethylenepentamine in 200 parts of water in parts by mass, then add 100 parts of digested shell powder, stir and disperse, pressurize under 0.4MPa pressure After soaking and absorbing for 0.5h, add 6 parts of gelatin, stir and react in a water bath at 60°C for 1h, then let it settle for 12h, discard the supernatant and dry it in vacuum at 80°C to obtain ammoniated shell powder;

[0033]S3: Dissolve nickel nitrate in deionized water, add sodium thiosulfate and nano-titanium oxide, stir evenly, hydrothermally crystallize at 100°C for 6 hours, centrifuge, wash, and dry to obtain nano-nickel sulfide / titanium oxide Composite; the mass ratio of n...

Embodiment 2

[0037] S1: add the shell powder to the acetic acid solution with a mass concentration of 12.5% and stir for 20 minutes, filter and calcinate at 650°C for 6 hours to obtain the digested shell powder; the mass ratio of the shell powder to the acetic acid solution is 1:5;

[0038] S2: Dissolve 15 parts of 4-amino-5-imidazole formamide and 6.5 parts of tetraethylenepentamine in 200 parts of water in parts by mass, then add 100 parts of digested shell powder, stir and disperse, pressurize under 0.6MPa pressure After impregnation and adsorption for 1 hour, add 8 parts of gelatin, stir and react in a water bath at 70°C for 1.5 hours, then let it settle for 12 hours, discard the supernatant and dry it in vacuum at 80°C to obtain ammoniated shell powder;

[0039] S3: Dissolve nickel nitrate in deionized water, then add sodium thiosulfate and nano-titanium oxide, stir evenly, hydrothermally crystallize at 125°C for 10 hours, centrifuge, wash, and dry to obtain nano-nickel sulfide / titan...

Embodiment 3

[0043] S1: add the shell powder to the acetic acid solution with a mass concentration of 15% and stir for 30 minutes, filter and calcinate at 800°C for 6 hours to obtain the digested shell powder; the mass ratio of the shell powder to the acetic acid solution is 1:5;

[0044] S2: Dissolve 20 parts of 4-amino-5-imidazole carboxamide and 8 parts of tetraethylenepentamine in 200 parts of water in parts by mass, then add 100 parts of digested shell powder, stir and disperse, pressurize under 0.8MPa pressure After impregnation and adsorption for 1 hour, add 10 parts of gelatin, stir and react in a water bath at 80°C for 2 hours, then let it settle for 12 hours, discard the supernatant and dry it in vacuum at 80°C to obtain ammoniated shell powder;

[0045] S3: Dissolve nickel nitrate in deionized water, then add sodium thiosulfate and nano-titanium oxide, stir evenly, hydrothermally crystallize at 150°C for 12 hours, centrifuge, wash, and dry to obtain nano-nickel sulfide / titanium o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com