Method for treating nuclear fuel element production process wastewater by utilizing vacuum membrane distillation

A vacuum membrane distillation, nuclear fuel element technology, applied in the fields of precipitation treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of inability to achieve "near zero" discharge, difficult to remove waste water impurities and ions, and unstable system performance. and other problems, to achieve the effect of reducing the difficulty of treatment, high effluent quality, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

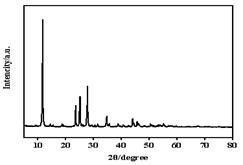

Image

Examples

Embodiment 1

[0020] Take 1000 mL of organic low-radioactive simulated wastewater (mainly containing urea, tetrahydrofurfuryl alcohol, PVA, ammonium nitrate, ammonia and uranium), adjust the pH of the solution to 5.0, pass the simulated wastewater into a constant temperature water heater, heat it to 75 °C, and then use peristaltic The pump passes the simulated wastewater into the tube side of the hollow fiber membrane module at a feed flow rate of 0.4 m / s for circulation, and uses a constant temperature cold water tank to feed cold water at 5 °C into the condensation device connected to the hollow fiber membrane module, so that the hollow fiber membrane Turn on the circulating water vacuum pump, adjust the vacuum pressure to -0.09 MPa, and vacuum the cold side of the membrane distillation device, so that a pressure difference is formed between the cold side end and the hot side end of the membrane module, and the water vapor in the wastewater is transported by the fiber membrane The inner si...

Embodiment 2

[0023] Take 5000 mL UO of a certain nuclear fuel element Co., Ltd. 2 Organic low-level radioactive wastewater (mainly containing urea, tetrahydrofurfuryl alcohol, PVA, ammonium nitrate, ammonia and uranium) generated during the core preparation process is filtered with filter paper to remove insoluble impurities in the water; the wastewater is passed into In the constant temperature water heater, heat it to 75 ℃, then use the peristaltic pump to pass the waste water into the tube side of the hollow fiber membrane module at a feed flow rate of 0.3m / s for circulation, and use the constant temperature cold water tank to flow into the condensing device connected to the hollow fiber membrane module Pass in cold water at 10 ℃ to form a temperature difference between the inside and outside of the hollow fiber membrane; turn on the circulating water vacuum pump, adjust the vacuum pressure to -0.085 MPa, and vacuum the cold side of the membrane distillation device, so that the cold side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com