Metal printing soft paint and preparation method thereof

A soft-feeling and coating technology, applied in polycarbonate coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor weather resistance, back-sticking of soft-touch coatings on iron printing, and unsatisfactory surface touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In addition, the present invention also provides a preparation method of a soft-touch coating for iron printing, the preparation method for preparing the soft-touch coating for iron printing as claimed in any one of claims 1-8, comprising the following steps:

[0038] Add the raw materials of the composite matting agent to the ball mill, and mix it for 5min-10min at a speed of 1000r / min-1500r / min, then use it for later use;

[0039] Add the water-based mixed resin to the mixing kettle, heat it to 65°C-75°C, then add coupling agent, dispersant, curing agent, film-forming agent, defoamer and solvent, at a speed of 500r / min-800r / min Stir and mix for 20min-30min to obtain mixture A;

[0040] Add the filler and the composite matting agent to the mixture A, stir and mix at a rotational speed of 1000r / min-1500r / min for 10min-15min to obtain the mixture B;

[0041] Add a leveling agent to the mixture B, and continue to stir and mix at a rotational speed of 300r / min-450r / min fo...

Embodiment 1-5

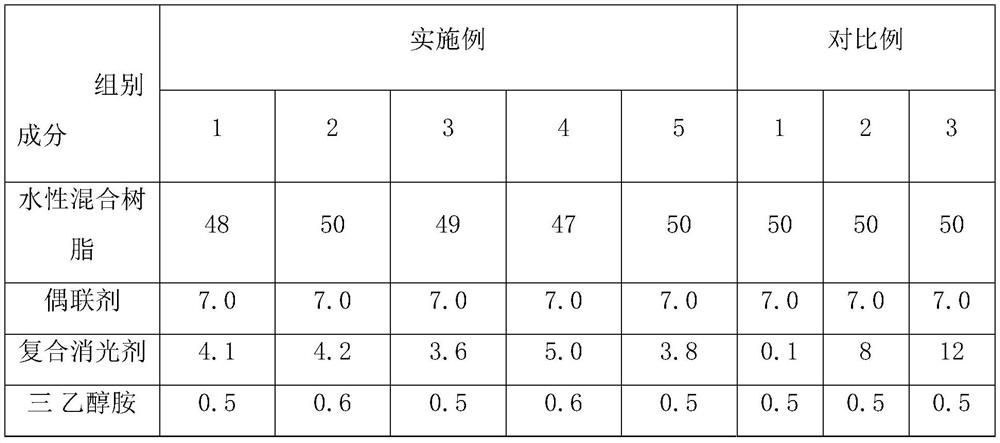

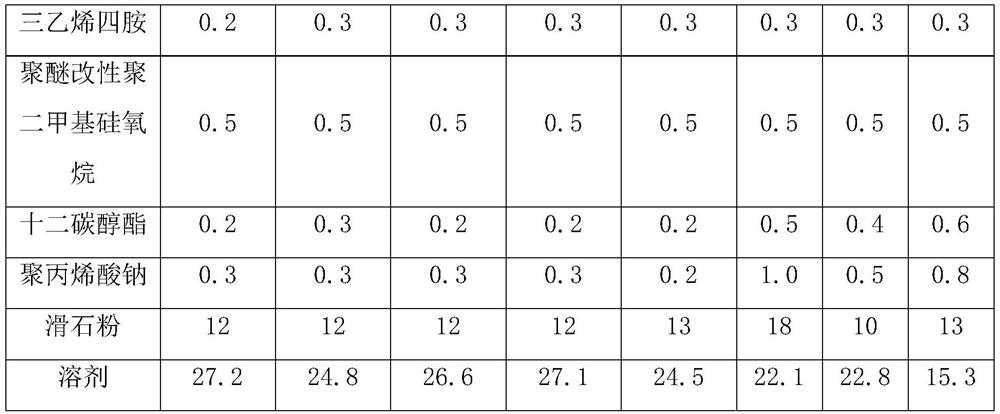

[0045] The mass percent of the preparation raw materials of Examples 1-5 is shown in Table 1;

[0046] The preparation method of a kind of printing iron soft-feeling paint of embodiment 1-5, comprises the following steps:

[0047] 10g of porous silica, 8g of Tween-80, 5g of polyurethane and 3g of polytetrafluoroethylene are added to the ball mill, and mixed by ball milling at a speed of 1000r / min-1500r / min for 5min-10min to obtain a composite matting agent, which is for later use;

[0048] Mix 20g of acrylic resin, 15g of polycarbonate polyurethane resin, 5g of organosilicon modified polyurethane resin and 10g of polycarbonate to obtain a water-based mixed resin for use;

[0049] Mix 3g of titanate with 4g of ethylenediaminepropyl triethoxysilane, as a coupling agent, for subsequent use;

[0050] Mix 50 mL of water with 50 mL of propanol as a solvent for later use;

[0051] The water-based mixed resin was added to the mixing kettle, heated to 75°C, and then the coupling agent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com