Preparation method of metal phase tungsten oxide and application of metal phase tungsten oxide

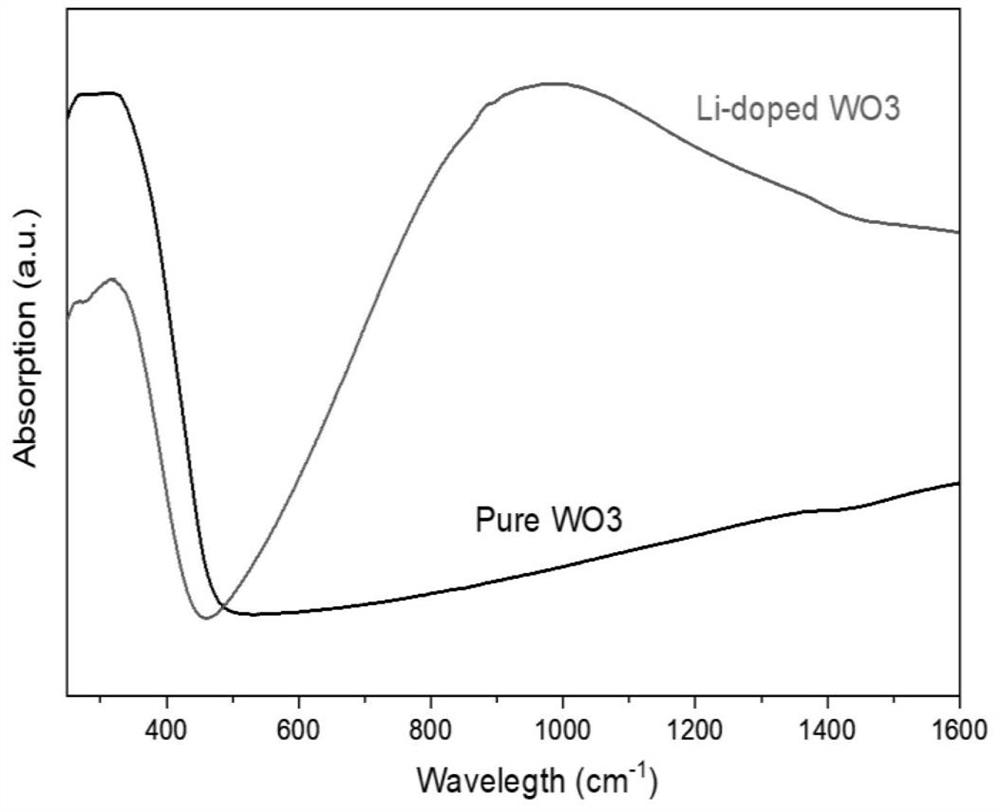

A phase tungsten oxide, metal technology, applied in the field of preparation technology and the application of photothermal therapy of biological cancer, can solve problems such as physiological toxicity, nanomaterial limitation, etc., to achieve enhanced absorption range and intensity, efficient photothermal conversion, and superior biological safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

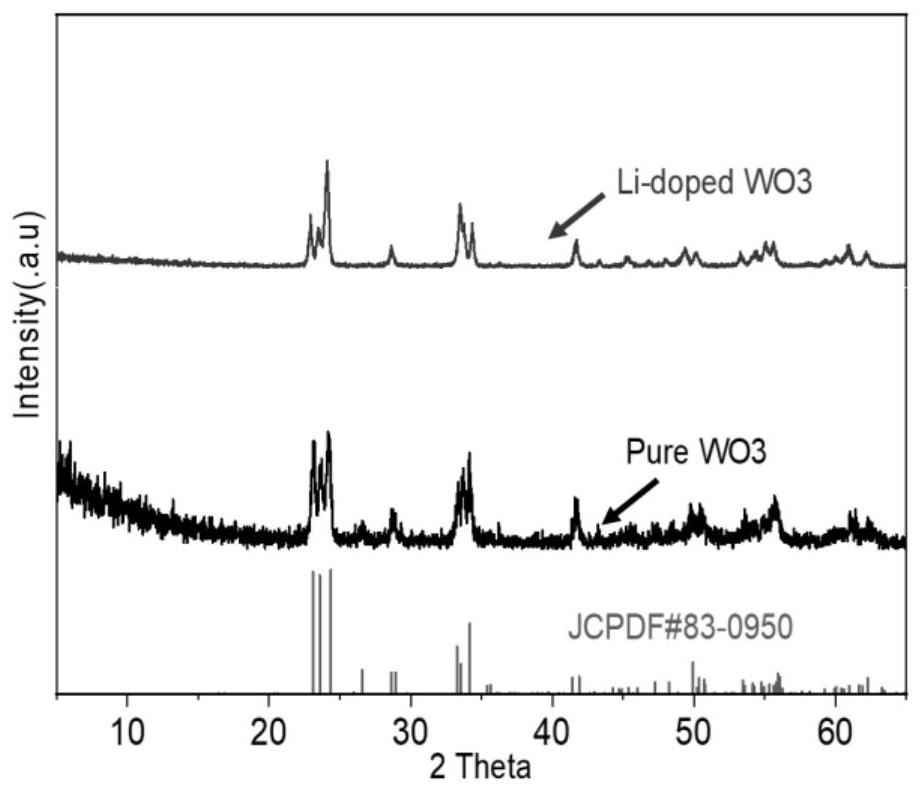

[0038] Based on the above exploration, this application aims at the practical technical problems existing in the preparation and photothermal anti-cancer application of existing tungsten oxide near-infrared conversion materials. The lithiation treatment method of light-to-heat conversion ability, specifically, the embodiment of the present invention discloses a preparation method of metal-phase tungsten oxide, including the following steps:

[0039] A) carrying out solvothermal reaction of polyethyleneimine, tungsten source and water to obtain precipitation;

[0040] B) Calcining the precipitate after drying to obtain WO 3 powder;

[0041] C) the WO 3 The powder is mixed with metal powder and then mixed with lithium salt solution to react to obtain Li-WO 3 ; The metal powder is selected from zinc powder, copper powder, magnesium powder or aluminum powder.

[0042] In the process of preparing metal-phase tungsten oxide, the polyethyleneimine, tungsten source and water under...

Embodiment 1

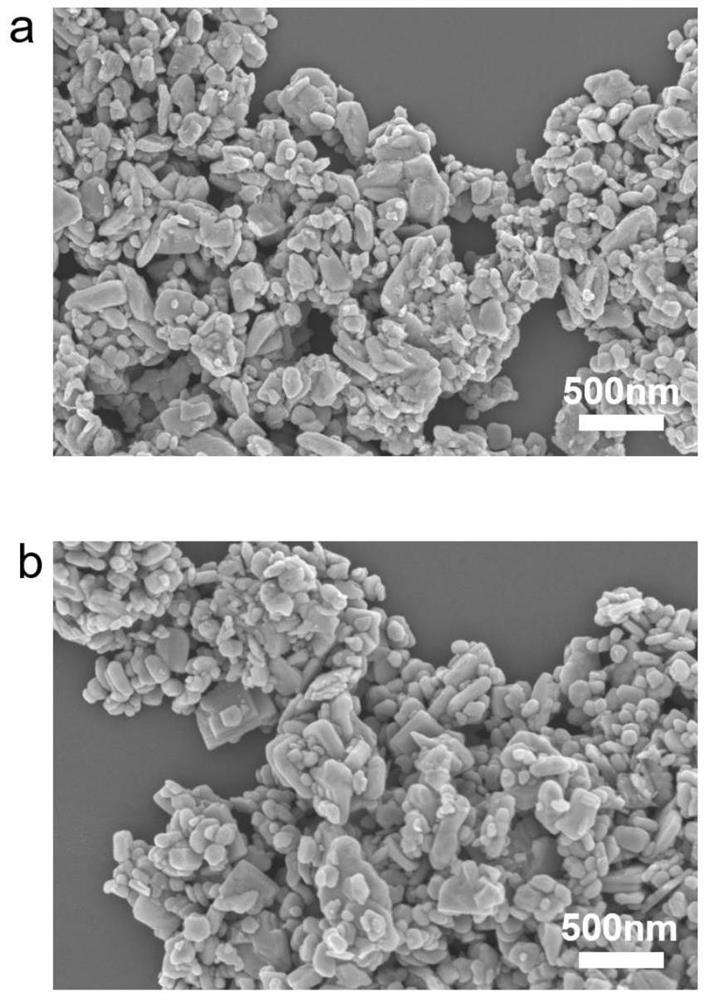

[0054] Weigh 0.3g of polyethyleneimine (molecular weight 10000), dissolve it in 15mL deionized water, then add 15mL concentration of 3M aqueous hydrochloric acid, then stir for 30 minutes, then add 30mL concentration of 0.3M Na to the above solution 2 WO 4 Solution, continue to stir for half an hour; finally, transfer the above mixed solution to a hydrothermal reaction kettle with a volume of 100mL, put it in a high-temperature oven, heat to 170°C and keep it warm for 12 hours;

[0055]After the hydrothermal reaction is completed and naturally cooled to room temperature, transfer the precipitate and solution in the hydrothermal reaction kettle to a centrifuge tube, centrifuge at a speed of 11,000 rpm for 3 minutes, wash with ethanol and deionized water three times, and dry in vacuum after centrifugation The oven was dried at 60°C to obtain powder, and the dried powder was placed in a ceramic crucible, and calcined in a muffle furnace in air at 500°C and kept for 4 hours to obt...

Embodiment 2

[0075] Weigh 0.35g of polyethyleneimine (molecular weight 20000), dissolve it in 15mL deionized water, then add 20mL concentration of 2.5M hydrochloric acid aqueous solution, then stir for 30 minutes, then add 30mL concentration of 0.28M hydrochloric acid to the above solution Na 2 WO 4 Solution, continue to stir for half an hour, and finally, transfer the above mixed solution to a hydrothermal reaction kettle with a volume of 100mL, put it in a high-temperature oven, heat to 160°C and keep it warm for 15 hours;

[0076] After the hydrothermal reaction is completed and naturally cooled to room temperature, transfer the precipitate and solution in the hydrothermal reaction kettle to a centrifuge tube, centrifuge at a speed of 10,000 rpm for 5 minutes, wash with ethanol and deionized water three times, and dry in vacuum after centrifugation The oven was dried at 60°C to obtain powder, and the dried powder was placed in a ceramic crucible, and calcined in a muffle furnace in air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com