Coated iron-carbon composite material, preparation method, modification method and sewage treatment method

A sewage treatment method and composite material technology, applied in the field of coating, can solve problems such as low compressive strength, and achieve the effects of increased strength, good barrier effect, and strong processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

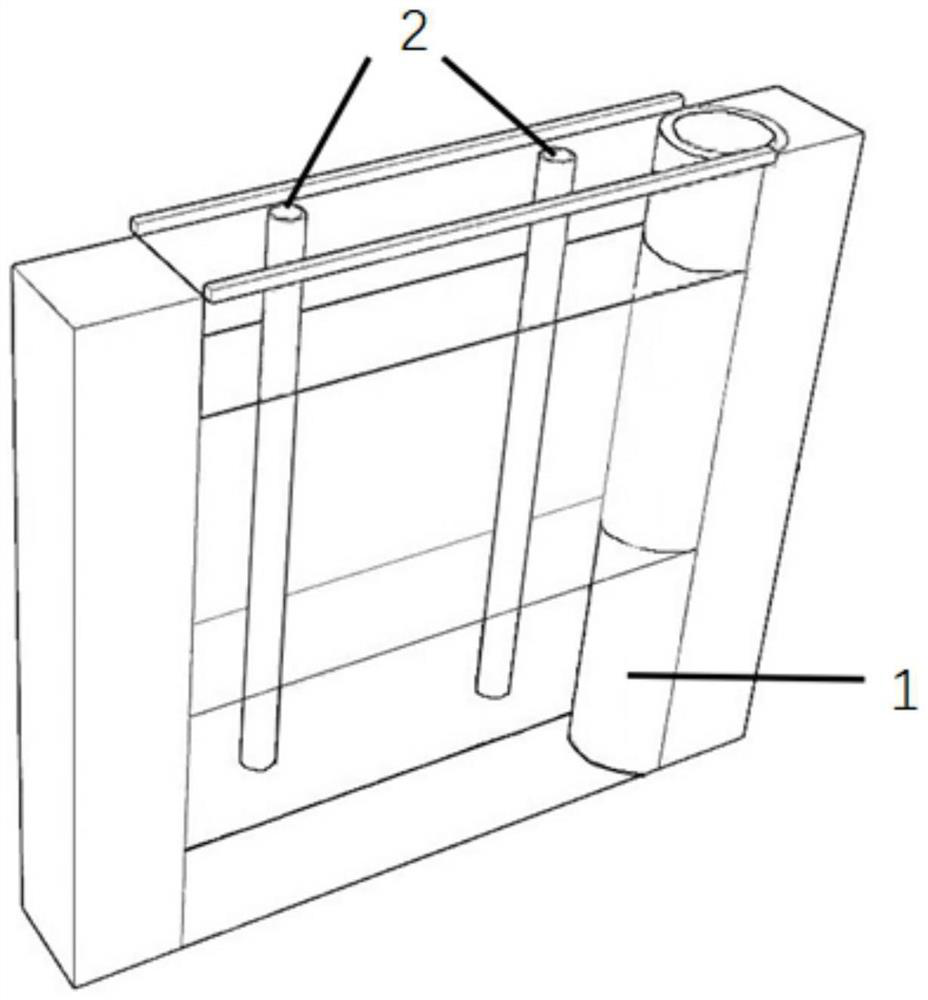

Image

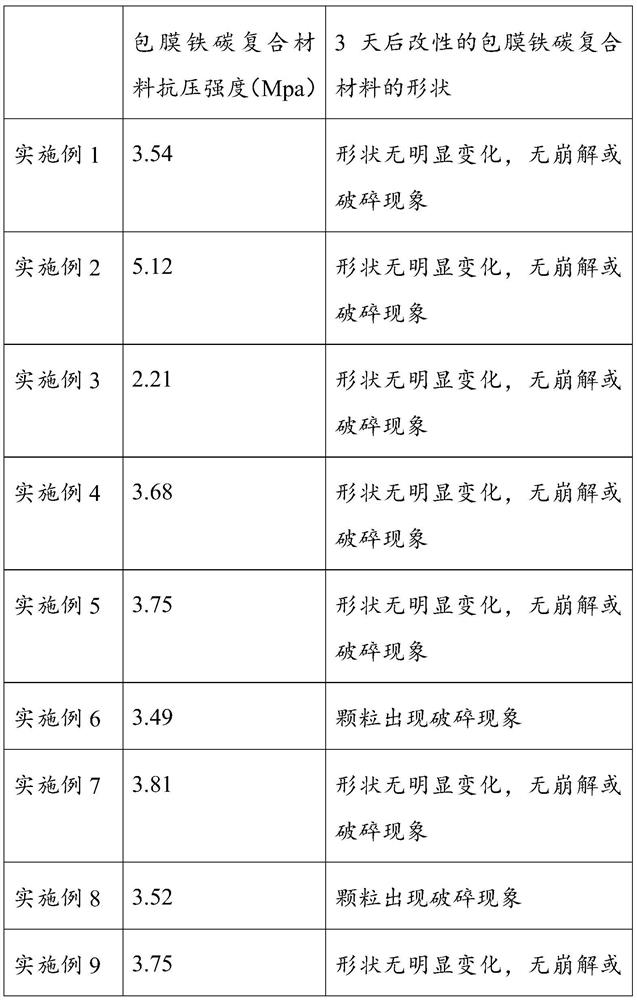

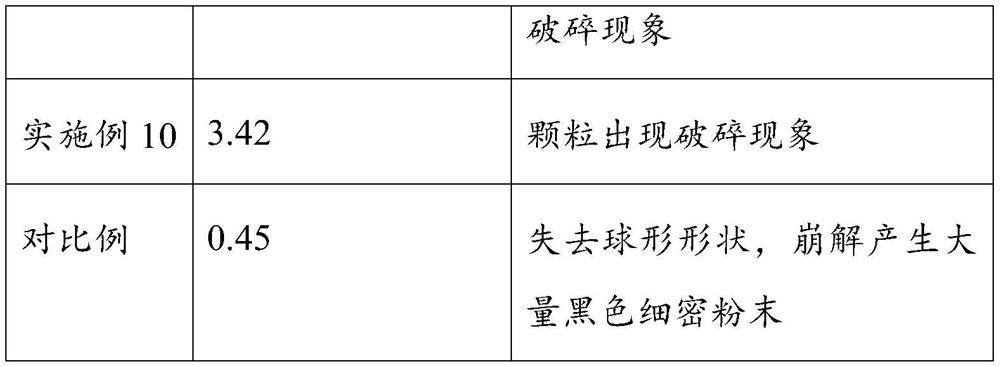

Examples

Embodiment 1

[0065] This embodiment provides a coated iron-carbon composite material, including 500 g of iron-carbon material and 20 g of coated polyethylene wrapped on its surface;

[0066] Among them, the iron-carbon material component includes 375g of iron powder, 100g of activated carbon powder, and 25g of sodium alginate powder.

[0067] This embodiment also provides a method for preparing the above-mentioned coated iron-carbon composite material, including the following steps:

[0068] (1) Preparation of iron-carbon material:

[0069] Preparation of pickling iron powder: Grind 500g of reduced iron powder to 200 mesh, place in 1000mL0.1 mol / L hydrochloric acid, stir for 5min, filter under reduced pressure, wash with deionized water until the pH value of the filtrate is 7.2, and vacuum oven at 50°C Dry for 2 hours and store in an oxygen-free environment.

[0070] Cross-linking and solidification: Grind the biological activated carbon to 200 mesh to obtain activated carbon powder. Ta...

Embodiment 2

[0078] This embodiment provides a coated iron-carbon composite material, including 465g of iron-carbon material and 46g of coated polyurethane DP3070A coated on its surface;

[0079] Wherein, the iron-carbon material component includes 400 g of iron powder, 50 g of graphite powder, and 15 g of sodium alginate powder.

[0080] This embodiment also provides a method for preparing the above-mentioned coated iron-carbon composite material, including the following steps:

[0081] (1) Preparation of iron-carbon material:

[0082] Preparation of pickling iron powder: Grind 500g of reduced iron powder to 400 mesh, place in 1000mL of 0.05mol / L sulfuric acid, stir for 4 minutes, filter under reduced pressure, wash with deionized water until the pH of the filtrate is 7.3, and place in a vacuum oven at 50°C Dry for 2 hours and store in an oxygen-free environment;

[0083] Cross-linking and solidification: Grinding graphite to 400 mesh to obtain graphite powder. Take 400g of dry picklin...

Embodiment 3

[0091] This embodiment provides a coated iron-carbon composite material, including 380g of iron-carbon material and coating material epoxy resin CYD-014U11g wrapped on its surface;

[0092] Wherein, the iron-carbon material component includes 200 g of iron powder, 150 g of activated carbon powder, and 30 g of sodium alginate powder.

[0093] This embodiment also provides a method for preparing the above-mentioned coated iron-carbon composite material, including the following steps:

[0094] (1) Preparation of iron-carbon material:

[0095] Preparation of pickling iron powder: Grind 500g of reduced iron powder to 300 mesh, place in 1000mL of 0.5mol / L nitric acid, stir for 3 minutes, filter under reduced pressure, wash with deionized water until the pH of the filtrate is 7.1, and place in a vacuum oven at 50°C Dry for 3 hours and store in an oxygen-free environment;

[0096] Cross-linking and solidification: Grind the bioactivated carbon to 300 mesh to obtain activated carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com