Injection gel containing controllably degradable polyester microspheres

A technology for degrading polyester and polyester microspheres, applied in the field of medical cosmetic materials, can solve the problems of collapse of the microsphere structure, particle adhesion, and the inability of PLLA microspheres to exist stably for a long time, so as to repair wrinkles and improve subcutaneous volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

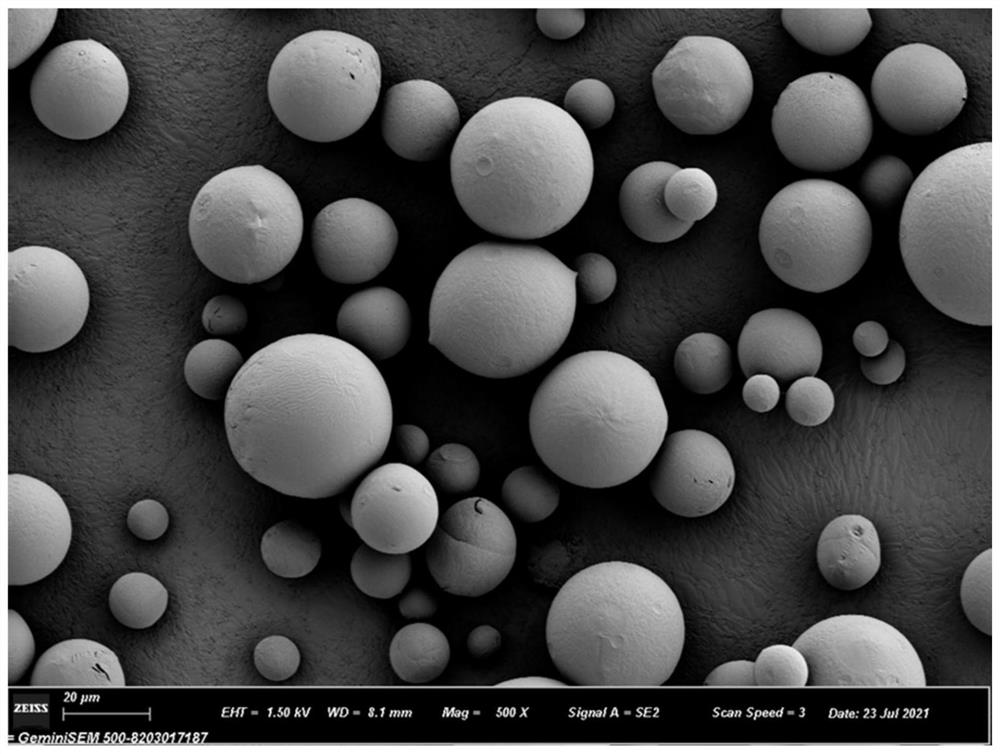

Image

Examples

Embodiment 1

[0037] S1: Preparation of PLLA microspheres wrapped in mixed fatty acid glycerides: 38-type mixed fatty acid glycerides were dissolved in petroleum ether to 2% solution; stirring, PLLA microspheres were added to the solution, making microspheres uniformly dispersed; The microspheres were separated from the solution.

[0038] S2: 10.0 g of sodium hyaluronate (dry powder) is dissolved in 100 ml of purified water, and then add 120 μl of crosslinking diendyl sulfone to the solution to mix well, add 30.5 g of mixed fatty acid glyceride wrapped in PLLA microspheres, stir After uniform reactions, 2 to 18 hours form a microspheres of cross-linking hyaluronicate;

[0039] S3: Brass the above gel into 1 ~ 2cm 3 The small gel block, then soaked, dialysis using a balanced salt solution;

[0040] S4: The gel after subjected to a dispersing machine, then the mass of 10% of the unfringed hyaluronicate (sodium sodium sodium sodium sodium sodium-sodium) is added to the balanced salt solution), and...

Embodiment 2

[0047] S1: Preparation of Glyceride (PCL) microspheres for mixed fatty acid glycerides: 36-type mixed fatty acid glycerides are prepared in chloroform into 6% solution; stirring, add PCL microspheres to solutions Make the microspheres uniformly dispersed; filtrate, separated the microspheres with the solution, the microspheres are placed in a normal temperature drum tank until the fatty acid glyceride wrapped PCL microspheres;

[0048] S2: 10.0 g of hyaluronate (dry powder) is dissolved in 100 ml of purified water, and then 120 μl of crosslinking diendoxide was added to the solution and mixed, then 11.4 g of a PCL microsphere wrapped in mixed fatty acid glyceride, stirred After uniform reactions, 2 to 18 hours form a microspheres of cross-linking hyaluronicate;

[0049] S3: Brass the above gel into 1 ~ 2cm 3 The small gel block, then soaked, dialysis using a balanced salt solution;

[0050] S4: The gel after subjected to a dispersing machine, then the mass of 10% of the unfringed ...

Embodiment 3

[0053] S1: Preparation of PLLA microspheres wrapped in mixed fatty acid glycerides: 37-type mixed fatty acid glyceride is dissolved in diethyl ether to 0.5% solution; stir it, add PLLA microspheres to the solution, make microspheres uniformly dispersed; Filter, separated the microspheres with the solution, and the microspheres were placed in a normal temperature shirt until drying, i.e., the PLLA microspheres wrapped in fatty acid glycerides;

[0054] S2: 10.0 g of hyaluronate (dry powder) is dissolved in 100 ml of purified water, and then 120 μl of crosslinking diendyl sulfone is added to the solution and mix, add 51.0 g of a PLLA microsphere wrapped in fatty acid glyceride, stir After uniform reactions, 2 to 18 hours form a microspheres of cross-linking hyaluronicate;

[0055] S3: Brass the above gel into 1 ~ 2cm 3 The small gel block, then soaked, dialysis using a balanced salt solution;

[0056] S4: The gel after subjected to a dispersing machine, then the mass of 10% of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com