Method for repairing covering film on surface of selenium drum powder-outlet knife

A powder knife and coating technology, which is applied to the electrical recording process using the charge pattern, the equipment of the electric recording process using the charge pattern, and the electrography, etc., can solve the problem of increased carbon powder accumulation, waste of resources, and loss of printing function and other issues, to achieve the effect of saving social resources, prolonging service life and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

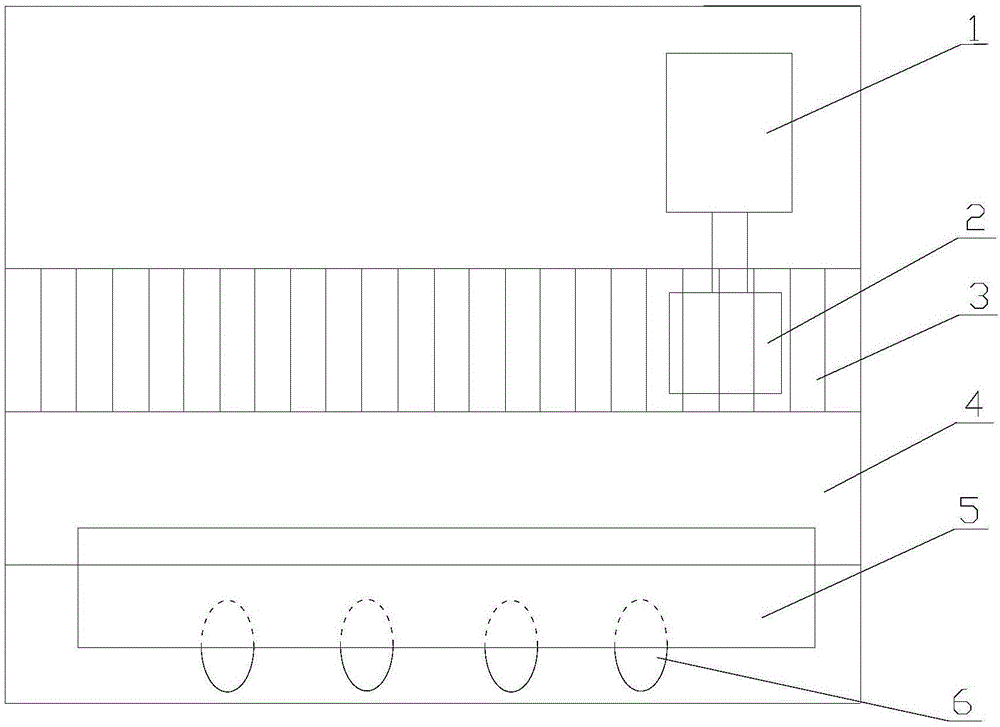

[0040] Image printing is carried out by using recycled powder knives, and the printing results obtained are as follows image 3 shown. Then remove the powder knife, and perform thermal repair on the powder knife. The repair steps include:

[0041] 1. Clean the surface of the discarded powder knives, and then check the surface shape of the powder knives under a 40X microscope to see if there is any damage. It was found that there was no damage on the surface of the powder knife. Under a 50X microscope, it was checked whether there were wrinkles on the surface of the powder knife. It was found that the polyurethane film on the surface of the powder knife had been damaged and could not be applied to the laser printer toner cartridge again and needed to be repaired.

[0042]2. Clean the surface of the powder knife that needs to be repaired, and then heat the surface of the powder knife instantly and then cool it down. The heating temperature described in the technical solution i...

Embodiment 2

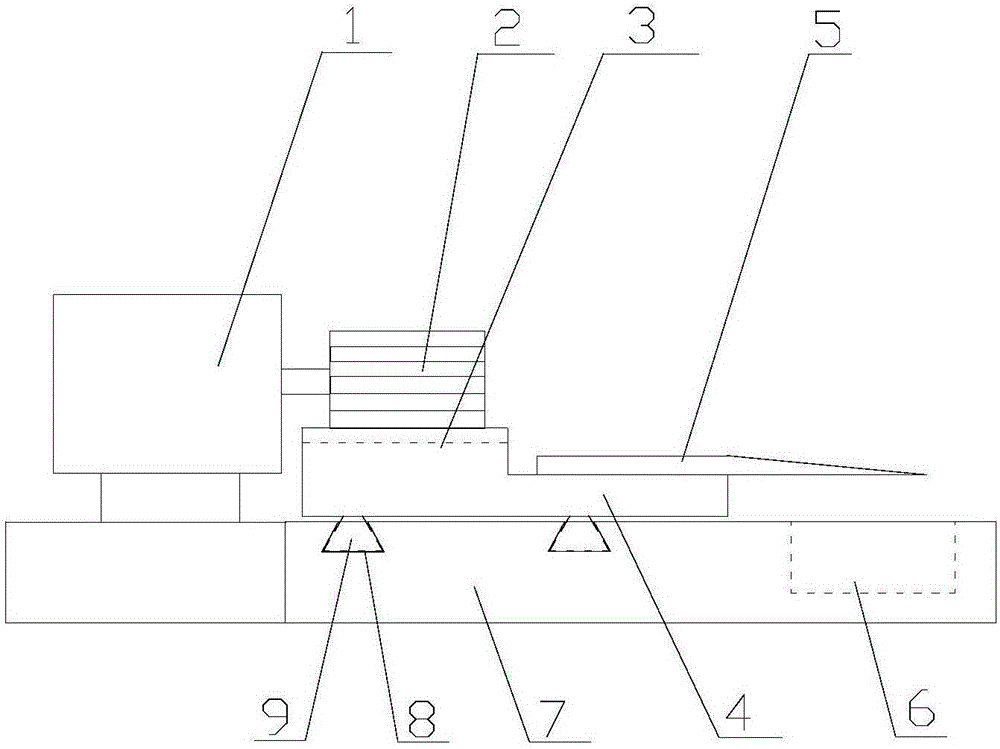

[0049] Image printing is carried out by using recycled powder knives, and the printing results obtained are as follows Figure 5 shown. Then remove the powder knife, and perform thermal repair on the powder knife. The repair steps include:

[0050] First, clean the surface of the powder outlet knife that needs to be repaired, and then heat the surface of the powder outlet knife instantaneously and then cool it down. The heating temperature described in the technical solution is 500° C., and the heating time is 0.1 second. Under the high temperature state, the polyurethane film softens, and the polyurethane film is stretched under the action of surface tension, so that the polyurethane film becomes a taut and smooth state. After the instant heating stops, the heat of the polyurethane film is quickly transferred to the metal blade, so that the temperature of the polyurethane film decreases rapidly, the smooth state of the surface of the polyurethane film is fixed, and the poly...

Embodiment 3

[0054] Image printing is carried out by using recycled powder knives, and the printing results obtained are as follows Figure 7 shown. Then remove the powder knife, and perform thermal repair on the powder knife. The repair steps include:

[0055] First, clean the surface of the discarded powder knives, and then detect the surface shape of the powder knives under a high-power microscope to see if there is any damage. If it is found that there is no damage on the surface of the powder knife, but there are wrinkles on the surface of the powder knife, the polyurethane film on the surface of the powder knife has been damaged, and it cannot be applied to the laser printer toner cartridge again, and needs to be repaired. Then clean the surface of the powder outlet knife that needs to be repaired, and then cool the surface of the powder outlet knife after being heated instantaneously. The heating temperature described in the technical solution is 100° C., and the heating time is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com