Radioactive decontamination wet tissue and preparation method thereof

A radioactive, wet wipe technology, applied in chemical instruments and methods, surface-active detergent compositions, detergent compositions, etc., can solve the problems of metal intergranular corrosion stress, difficult to handle, limited application, etc., to improve the density of fabrics , cost saving, the effect of strong complexation and dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

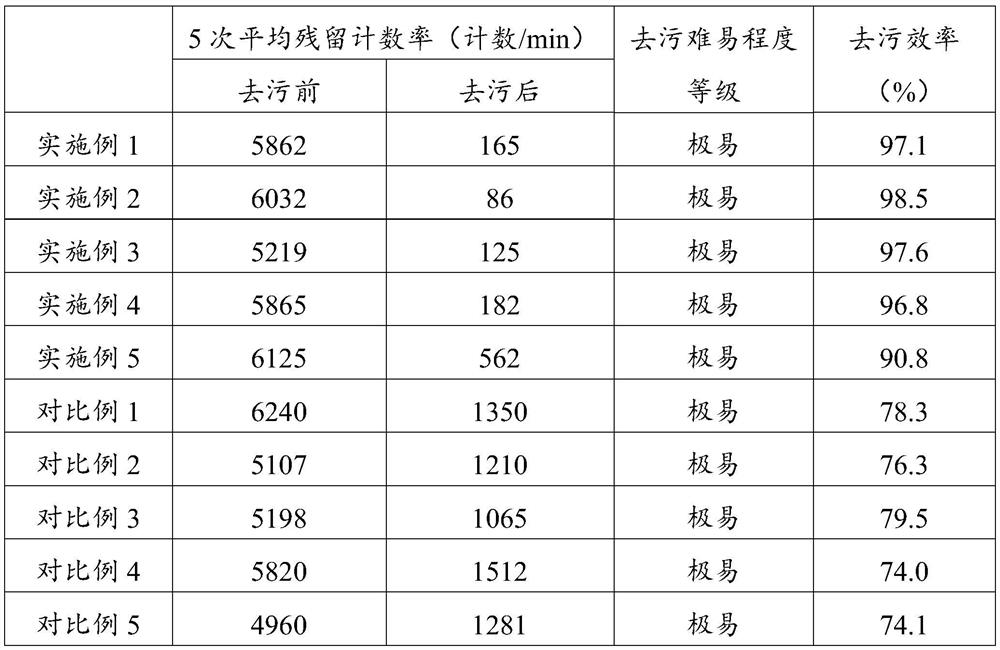

Examples

preparation example Construction

[0023] The present invention also provides a preparation method of radioactive decontamination wet wipes, comprising the following steps in sequence:

[0024] (1) Select ultra-fine fiber dust-free cloth made of double-woven polyester fiber and carry out cold cutting and ultrasonic edge sealing;

[0025] (2) Cleaning with ultrapure water in the ultra-clean workshop;

[0026] (3) Soak in a decontamination solution comprising ultrapure water, fatty alcohol polyoxyethylene ether, isopropanol, 2-carboxyphosphonoacetic acid and pentasodium diethylenetriaminepentaacetate;

[0027] (4) Encapsulate with outer packaging.

[0028] Among them, the polyester fiber is pure (i.e. 100%) polyester fiber material, the ultrapure water can be 18 megohm ultrapure water, the ultrafine fiber dust-free cloth is soaked in the decontamination solution for 20-40min, and the outer packaging is aluminum foil bags or plastic bags.

Embodiment 1

[0031] A radioactive decontamination wet tissue, comprising a wet tissue body, a decontamination solution soaked in the wet tissue body, and an outer package for containing the wet tissue body and the decontamination solution, the wet tissue body is folded in the outer package in a continuous pumping manner, The outer packaging is aluminum foil packaging bag. The wet wipe body is made of dust-free cloth, and has a two-layer structure with a base layer and a surface layer, and the base layer and the surface layer are respectively woven by 100% polyester fiber in the longitude and latitude directions. In terms of weight percentage, the raw materials for the preparation of the decontamination solution include 85% of 18 megohm ultrapure water, 2% of narrowly distributed C9-11 fatty alcohol polyoxyethylene ether, 11% of isopropanol, and 1% of 2-carboxyphosphine Acylacetic acid and 1% pentasodium diethylenetriaminepentaacetate.

[0032] The preparation method of this radioactive de...

Embodiment 2

[0038]A radioactive decontamination wet tissue, comprising a wet tissue body, a decontamination solution soaked in the wet tissue body, and an outer package for containing the wet tissue body and the decontamination solution, the wet tissue body is folded in the outer package in a continuous pumping manner, The outer packaging is aluminum foil packaging bag. The wet wipe body is made of dust-free cloth, and has a two-layer structure with a base layer and a surface layer, and the base layer and the surface layer are respectively woven by 100% polyester fiber in the longitude and latitude directions. In percent by weight, the raw materials for the preparation of the decontamination solution include 93% of 18 megohm ultrapure water, 1% of narrowly distributed C9-11 fatty alcohol polyoxyethylene ether, 5% of isopropanol, and 0.5% of 2-carboxyphosphine Acylacetic acid and 0.5% pentasodium diethylenetriaminepentaacetate.

[0039] The preparation method of this radioactive decontami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com