Dispersive basic copper chloride and preparation method thereof

A cupric chloride, dispersed technology, applied in the direction of cupric chloride, cupric halide, additional food elements, etc., can solve the problem of increased process flow, reduced effective content of basic cupric chloride in products, complicated crystallization scheme of copper-containing ammonium chloride and other problems, to achieve the effects of improved dispersibility, less agglomeration, and improved crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

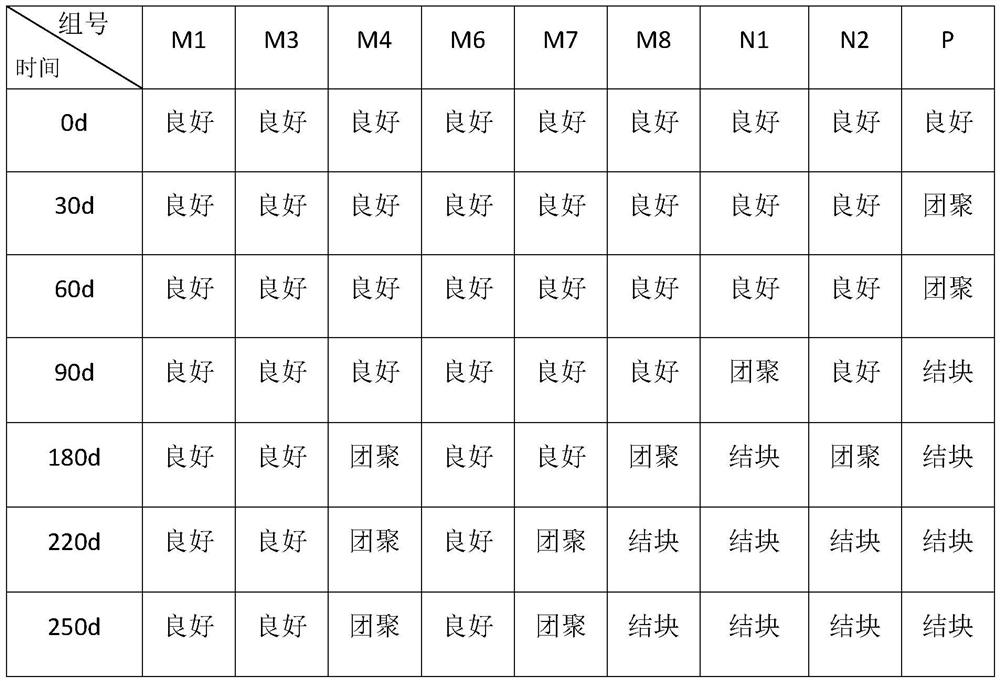

Examples

Embodiment 1

[0033] Example 1 (prior to reaction, 85 ° C, 4H, 2%, Gly-Cu; 2: 3)

[0034] 34.4GCUCL 2 · 2h 2 O Soluble in 150 ml of pure water, add 0.9 g of glycine copper chelate to the above-mentioned copper chloride solution to transfer 500 ml of four flasks 50 ° C to heat insulation; weigh 24.1 GCUO and 150 ml of pure water to be configured into suspension, one and In the 500 ml of the four-mouth flask, stirring to obtain a black suspension mixing system, heating to 85 ° C insulation reaction for 4 h, the reaction ends naturally cooling to the system 30 ~ 40 ° C, filtration washing, washed with light green microstructure, 105 ° C dry to constant weight, Light green micro-blue powder solid M1: Net weight 41.25g, good fluidity, slightly gloss, analyzed the solid copper content: 58.44%. The mother liquor is about 250 ml of microfluorescent stated: remembered MY-01, its pH is 3.11.

Embodiment 2

[0035] Example 2 (Circulation 1)

[0036] Take the first mother liquor MY-01, adjust its pH = 2.5 to 2.7 with a 10% hydrochloric acid solution, resulting in the regeneration mother liquor 1, take 150 ml of regenerated mother liquor 1 to dissolve 17.2GCUCL 2 · 2h 2 O, the blue-green solution is transferred to 500 ml of four flasks and then add 0.9 g of glycine chelating copper 50 ° C to be used; the remaining regenerative mother liquor is supplied into a small amount of pure water to 150 mL and 24.1 GCUO is configured into a suspension, add the aforementioned 500 ml of flask , Stirring to obtain a black suspension mixing system, warming to 85 ° C stirring insulation reaction for 4 h, the reaction ends naturally cooling to the system 30 to 40 ° C, the filtration is washed with light green micro-blue solid, 105 ° C dry to constant weight, light green microstru Powder solid M1: net weight 40.78g, good fluidity, slightly gloss, analyzed the solid copper content: 58.26%. The mother liqu...

Embodiment 3

[0037] Example 3 (before, 70 ° C, 2H, 5%, GLYCU)

[0038] Operation with Example 1, only the reaction temperature was reduced to 70 ° C, and the amount of glycine chelating copper was increased to 2.1 g (5 wt%), and the reaction time was shortened to 2 h. Finally, the delaid powder solid M3: net weight is 43.44 g, the fluidity is good, slightly gloss, analyzed the solid copper content: 57.85%. The mother liquor is about 280 ml of microfluorescent stickers: remembered MY-03, its pH of 2.97.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com