Burr polishing device for sealing gasket mounting hole

A technology for mounting holes and gaskets, which is applied to grinding drive devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., and can solve the problems of reduced sealing performance between holes and assemblies, and burrs in holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS It should be understood that the specific embodiments described herein are intended to illustrate and explain the invention and are not intended to limit the invention.

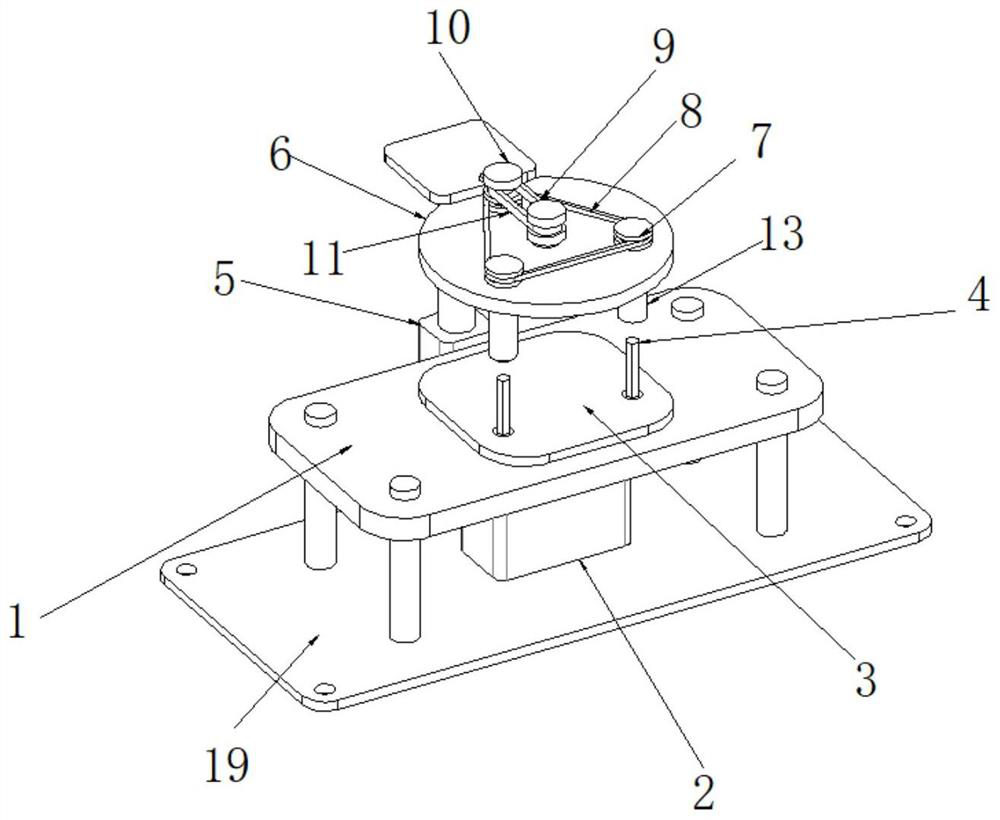

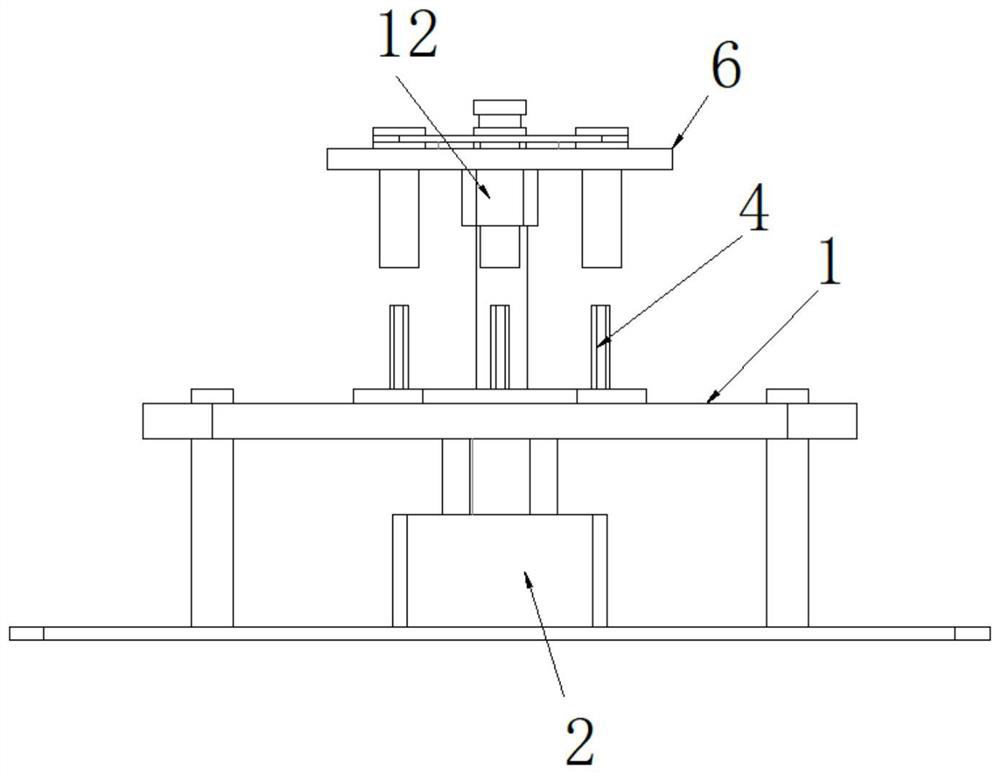

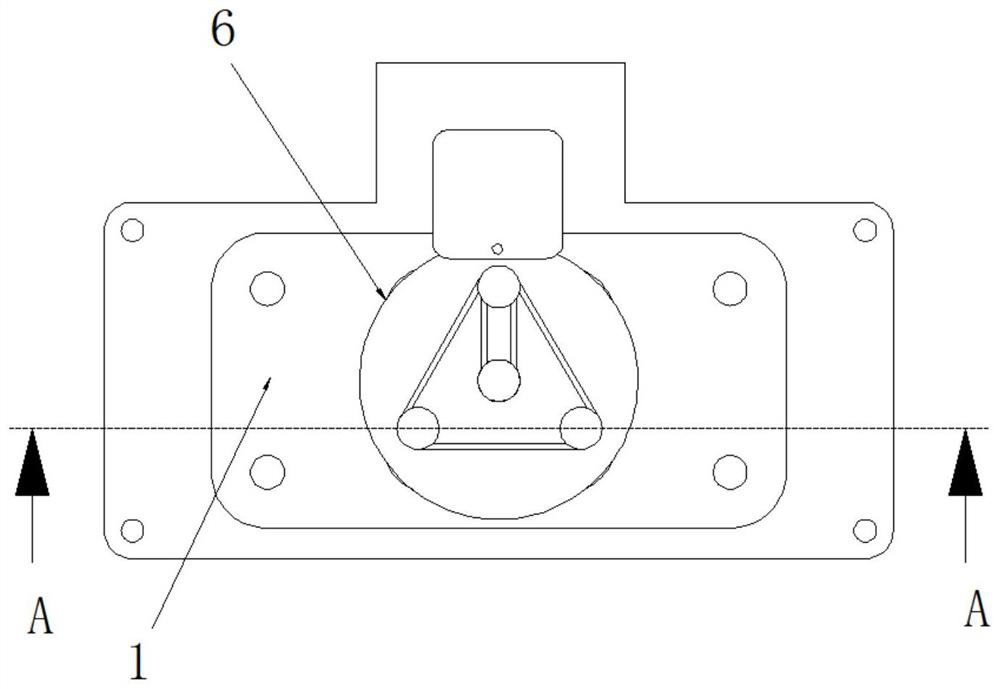

[0024] Such as Figure 1-5 As shown: The present invention provides a burr-grinding device for sealing pad mounting holes, characterized in that the burr grinding means comprises a base 1, which is rotatably disposed on the surface of the susceptor 1. The rotating rod 4 fixed to the grinding column 15 is disposed over the base 1 and can be displaced in the vertical direction, disposed on the pressure plate 6 and corresponds to one or one with the drive rod 4. The rotating sleeve 13 is disposed on the pressure plate 6; when the pressure plate 6 moves downward, it can be opposed to the rotational rod 4; the drive assembly can be driven by the rotating sleeve 13. The rod 4 rotates. When the seal pad 3 is placed on the base 1, the grinding column 15 is engaged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com