Buckling type seal structure of cross axle cardan joint

A cross shaft universal and sealing structure technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem of easy wear and aging of sealing materials, affecting the service life of universal joints, and the decline of sealing performance of universal joints and other problems, to achieve the effect of compact structure, low production cost and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

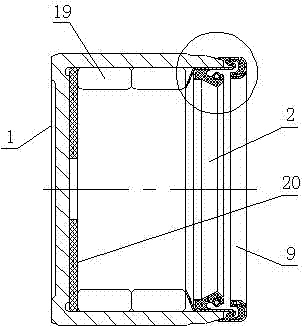

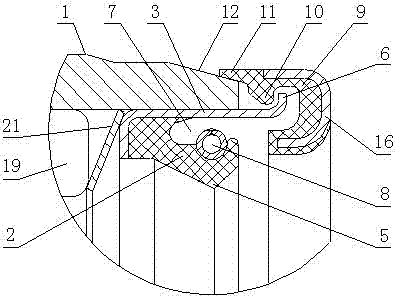

[0022] exist figure 1 figure 2 In the shown embodiment 1, a cross-axis universal joint buckle-type sealing structure includes an outer ring 1, a sealing ring 2 and a dust cover 9, and the outer ring is a cylinder with an open end and a closed end Shaped structure, the outer diameter of the outer ring is 55 mm, the wall thickness is 2.5 mm, the inner side of the opening end of the outer ring is provided with a sealing ring, the sealing ring includes a sealing ring skeleton 3 with an interference fit with the outer ring and a cross Shaft universal joint 4 journal fitted seal lip 5 (see image 3 , not shown in the figure of the universal joint journal), one end of the sealing ring skeleton is folded inward and connected with the sealing lip integrally, and the other end of the sealing ring skeleton is turned outward to form a hook body ring 6, and there is a set between the sealing lip and the sealing ring skeleton Annular groove 7, a pre-tightening groove is provided on the s...

Embodiment 2

[0024] exist Figure 4 In the shown embodiment 2, the outer ring is a cylindrical structure with an open end and a closed end integrally formed by a steel plate, the outer ring is a structure with a substantially equal wall thickness, and the outer diameter of the outer ring is 70 mm , the wall thickness is 3.5 mm, and the inner side of the opening end of the outer ring on the dust-proof sealing surface of the outer ring opening end is provided with a sealing ring mounting seat 15 with a stepped structure (see Figure 6 ), the inner diameter of the sealing ring mounting seat is 1.5mm larger than the inner diameter of the outer ring, the sealing ring is fixed on the sealing ring mounting seat through the sealing ring skeleton, and the interference fit between the sealing ring skeleton and the sealing ring mounting seat; the sealing lip and the sealing ring A secondary sealing lip 13 is provided between the inner flanges of the skeleton (see Figure 5 ), the auxiliary sealing l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com