Multi-stage multi-pole magnetic powder sealing device

A sealing device and multi-pole magnetic technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve the problems of increased leakage rate, loss of sealing effect, and reduced pressure resistance of the magnetic powder sealing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

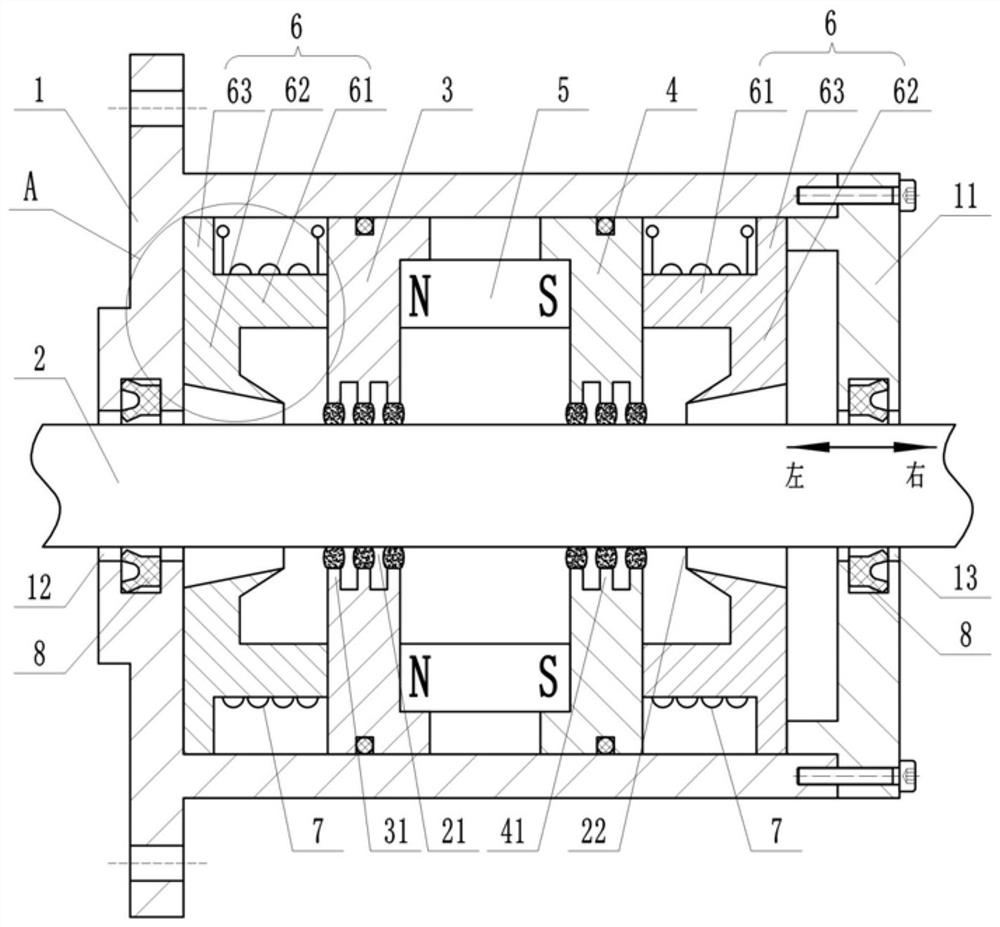

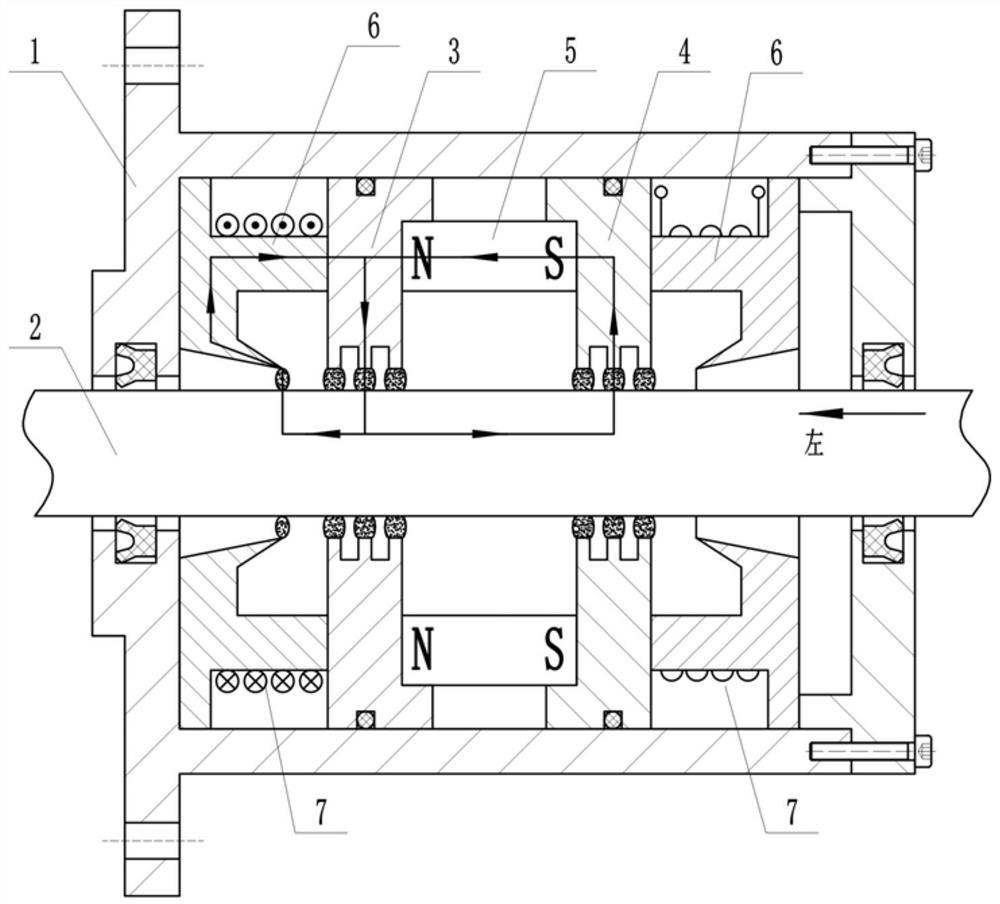

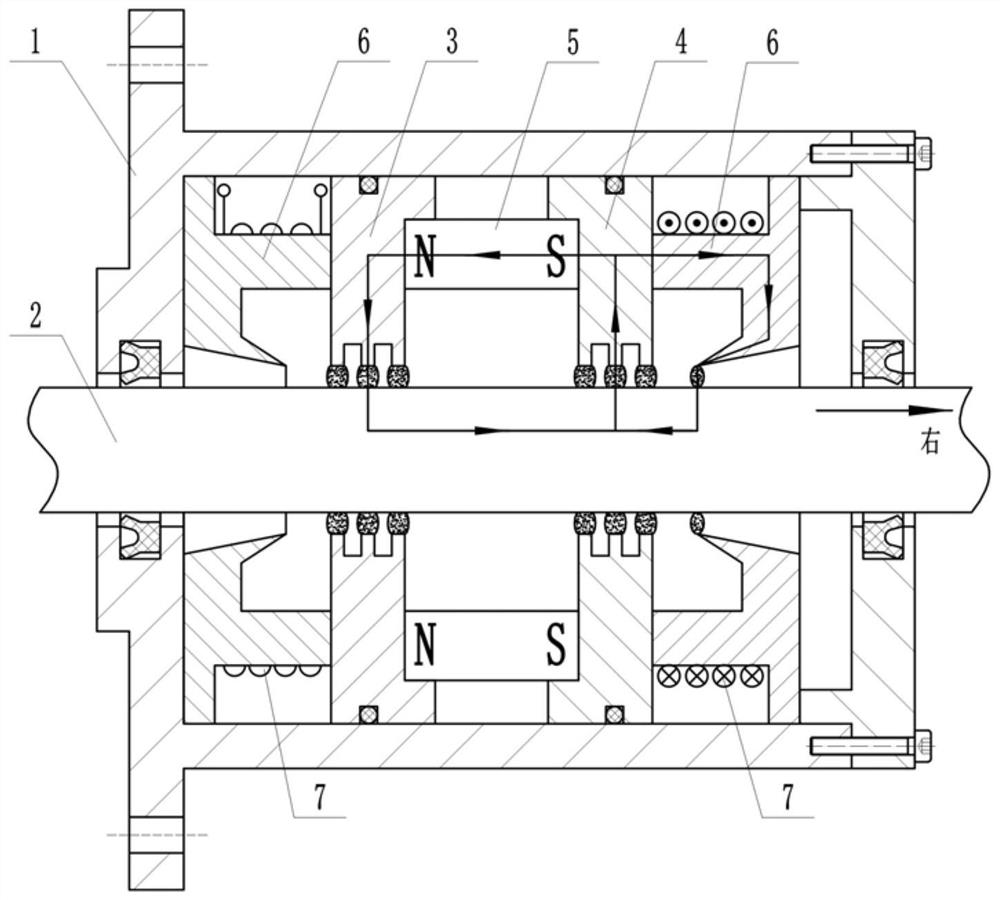

[0032] Such as figure 1 As shown, the multi-stage multi-pole magnetic powder sealing device according to the embodiment of the present invention includes a housing 1 , a reciprocating shaft 2 , a first pole piece 3 , a second pole piece 4 , a permanent magnet 5 and a sealing assembly 6 .

[0033] Wherein, the reciprocating shaft 2 runs through the housing 1, and the reciprocating shaft 2 can be along the axial direction of the reciprocating shaft 2 relative to the housing 1 (such as figure 1 left and right directions shown in ) to reciprocate. The first pole shoe 3 is arranged in the casing 1 and sleeved on the outside of the reciprocating shaft 2. The inner pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com