Method for breaking and repairing outer sheath in cooperation with repairing of high-voltage cable buffer layer

A technology for high-voltage cables and outer sheaths, which is applied in the field of outer sheath removal and repair in conjunction with the repair of high-voltage cable buffer layers. Excellent sealing performance, the effect of ensuring sealing performance and electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

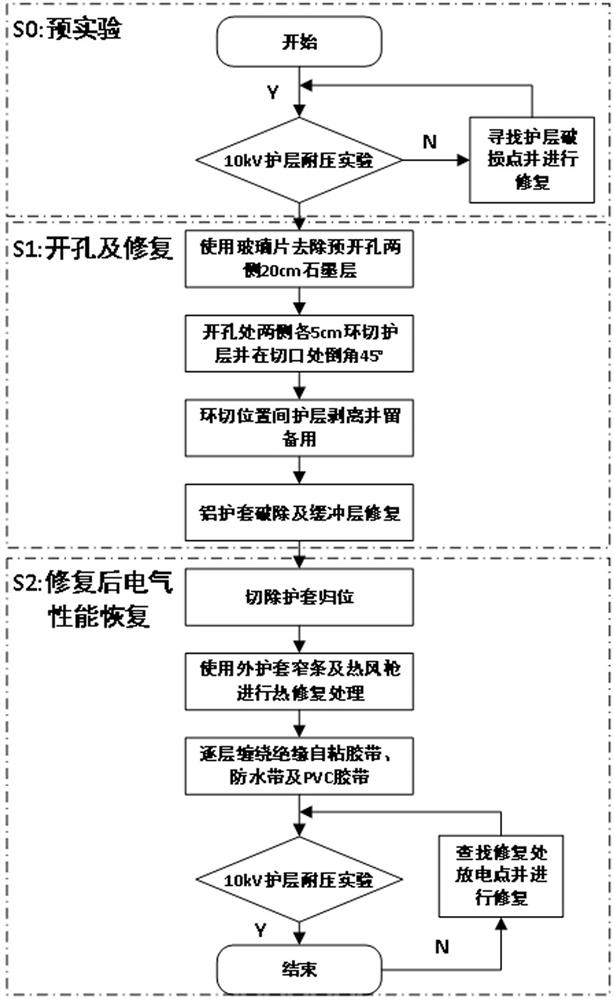

[0034] A method for removing and repairing the outer sheath in conjunction with the repair of the high-voltage cable buffer layer, such as figure 1 shown, including the following steps:

[0035] Step 1. Conduct a pre-test on the cable to be repaired.

[0036] Conduct the sheath withstand voltage test on the cable to be repaired. If the test passes, go to step 2. Otherwise, find the damaged point of the sheath and repair it. After the repair is completed, repeat this step until the sheath withstand voltage test passes.

[0037] Step 2. Remove the outer sheath of the cable.

[0038] Step 2.1, removing the graphite layer or semiconductive layer within a certain range on both sides of the pre-opened hole.

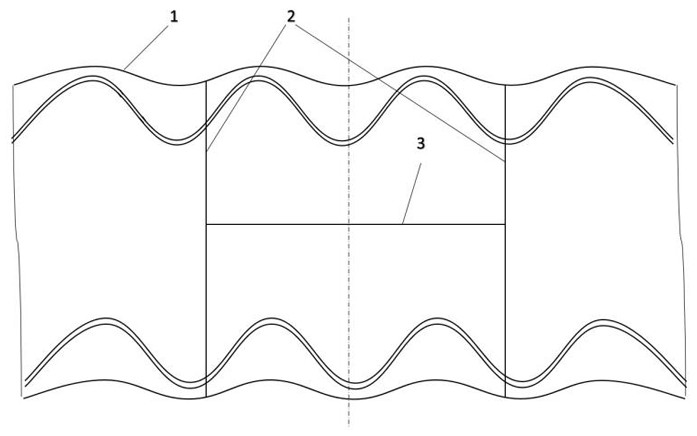

[0039] The preparation method of the solder for filling is as follows: prepare a section of the outer sheath of the same material as the outer sheath 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com