Sealing device for hydraulic pump of nuclear power station

A technology for sealing devices and hydraulic pumps, which is applied to components of pumping devices for elastic fluids, engine seals, pump components, etc., and can solve problems such as hydraulic pump seal failure, design and disassembly difficulties, and high-pressure steam leakage , to achieve the effect of ensuring sealing performance, reducing the risk of scratches, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the embodiments described below are only a part of the embodiments of the present application, not all of them. Based on the embodiments described in this application, all other embodiments obtained by those skilled in the art without creative efforts are within the protection scope of this application.

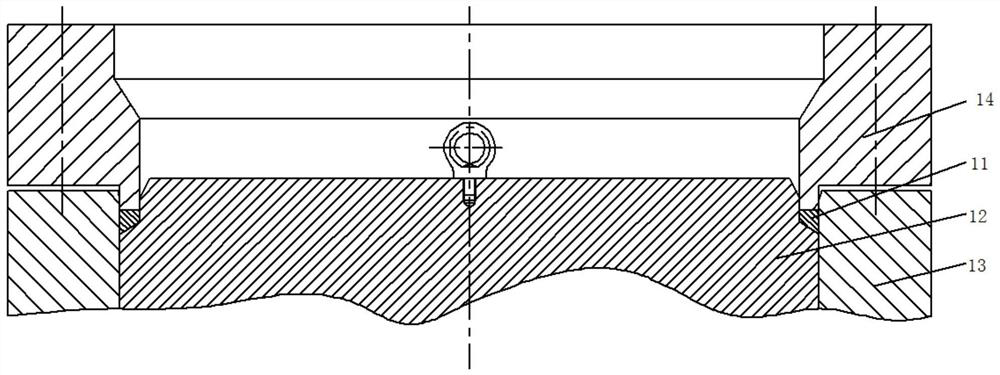

[0033] The inventors of the present application have found in research, such as figure 1 As shown, in an existing sealing device for a hydraulic pump in a nuclear power plant, the sealing ring 11 is a self-sealing structure with a conical surface, and the material is austenitic stainless steel. The outer circular surface of the ring 11 cooperates with the inner wall of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com