Monatomic site iron catalyst with adjustable coordination environment as well as preparation method and application of monatomic site iron catalyst

An iron catalyst and environment technology, which is applied in the preparation of single-atom catalyst materials and its application fields, can solve the problem of single-atom active coordination environment and electronic structure regulation method, low load of active species at single-atom site, and unfavorable industrial application, etc. problem, to achieve the effect of easy scale-up experiment, low cost and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a single-atom site iron catalyst with an adjustable coordination environment, comprising the following steps:

[0042] A. Dissolve 8mmol ferrocene formaldehyde in 25mL 1,4-dioxane, stir and mix to form a uniform solution, then transfer it to an ice-water bath, add 1.4mL concentrated sulfuric acid (98wt%) to obtain acidification 25 mL of 1,4-dioxane containing 0.56 mL of pyrrole was then added dropwise to the acidified ferrocene formaldehyde solution, and the stirring was continued in an ice-water bath for 24 hours;

[0043] B. After step A is completed, heat it under reflux at 60°C for 6 hours. After the reaction is completed, precipitate and cool, then deprotonate with 5mL ammonia water, filter, wash and dry after 4 hours to obtain the precursor;

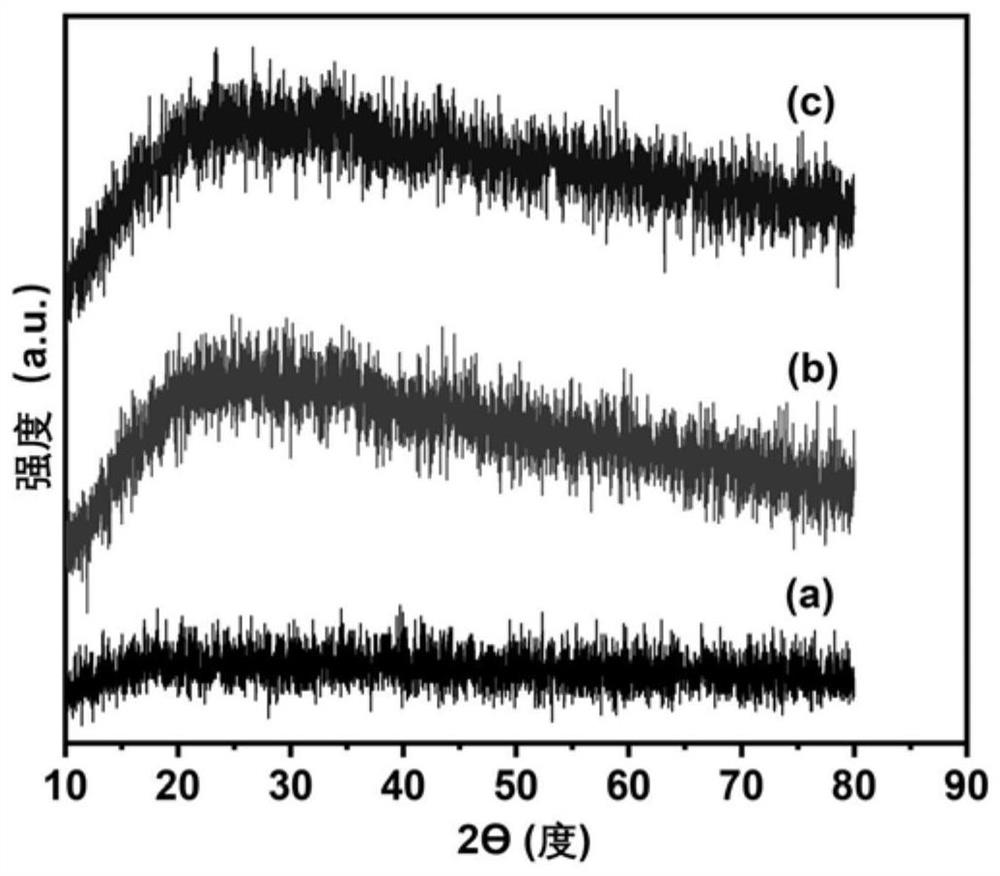

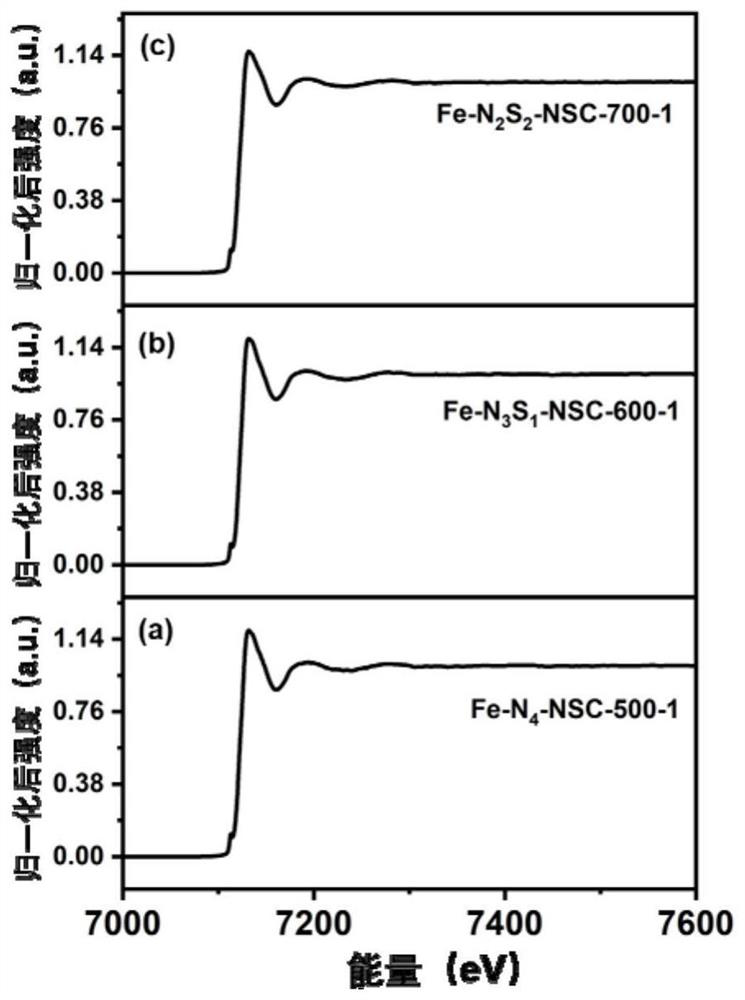

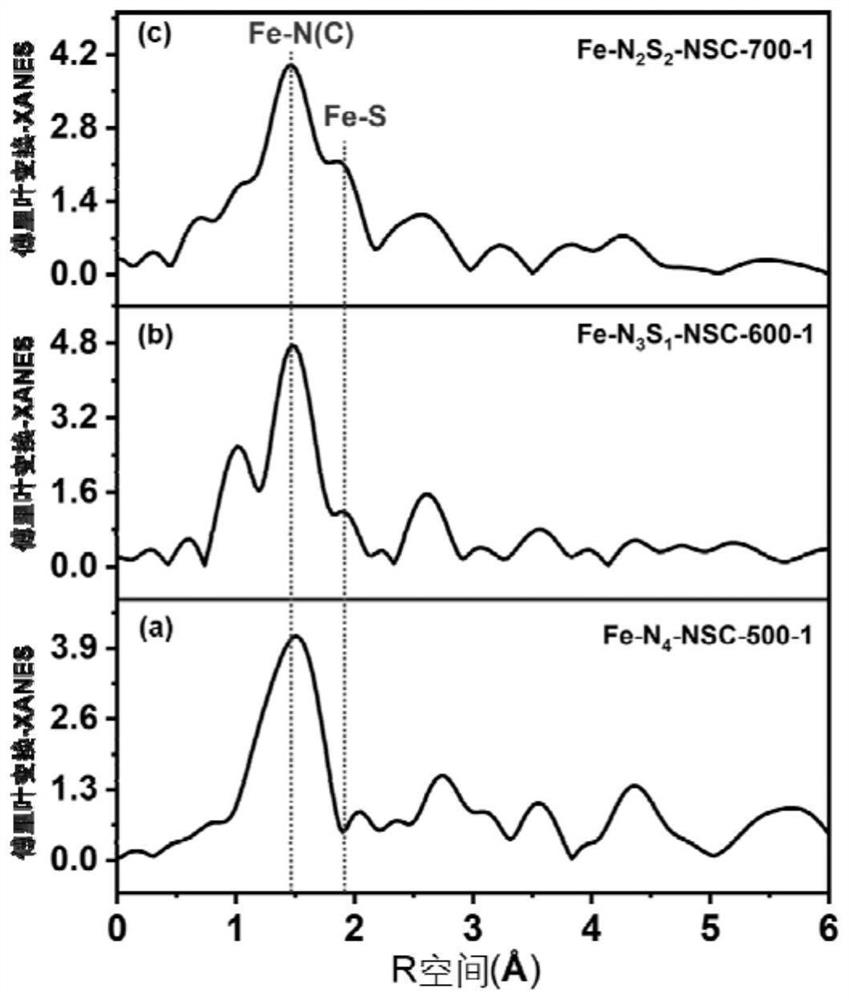

[0044] C. Grind 1g of the precursor prepared in step B with 1g of melamine for 2 hours, put it in a tube furnace under a nitrogen atmosphere, and pyrolyze it at 500°C for 3 hours. The product is named:...

Embodiment 2

[0052] A method for preparing a single-atom site iron catalyst with an adjustable coordination environment, comprising the following steps:

[0053] A. Dissolve 8mmol ferrocene formaldehyde in 25mL 1,4-dioxane, stir and mix to form a uniform solution, then transfer it to an ice-water bath, add 1.4mL concentrated sulfuric acid (98wt%) to obtain acidification 25 mL of 1,4-dioxane containing 0.56 mL of pyrrole was then added dropwise to the acidified ferrocene formaldehyde solution, and the stirring was continued in an ice-water bath for 24 hours;

[0054] B. After step A is completed, heat it under reflux at 60°C for 6 hours. After the reaction is completed, precipitate and cool, then deprotonate with 5mL ammonia water, filter, wash and dry after 4 hours to obtain the precursor;

[0055] C. Grind 1g of the precursor prepared in step B with 1g of melamine for 2 hours, put it in a tube furnace under a nitrogen atmosphere, and pyrolyze it at 600°C for 3 hours. The product is named:...

Embodiment 3

[0064] A method for preparing a single-atom site iron catalyst with an adjustable coordination environment, comprising the following steps:

[0065] A. Dissolve 8mmol ferrocene formaldehyde in 25mL 1,4-dioxane, stir and mix to form a uniform solution, then transfer it to an ice-water bath, add 1.4mL concentrated sulfuric acid (98wt%) to obtain acidification 25 mL of 1,4-dioxane containing 0.56 mL of pyrrole was then added dropwise to the acidified ferrocene formaldehyde solution, and the stirring was continued in an ice-water bath for 24 hours;

[0066] B. After step A is completed, heat it under reflux at 60°C for 6 hours. After the reaction is completed, precipitate and cool, then deprotonate with 5mL ammonia water, filter, wash and dry after 4 hours to obtain the precursor;

[0067] C. Grind 1g of the precursor prepared in step B with 1g of melamine for 2 hours, put it in a tube furnace under a nitrogen atmosphere, and pyrolyze it at 700°C for 3 hours. The product is named:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com