Dustproof film for lens surface of optical device

A technology for optical devices and dust-proof films, which is applied in the field of dust-proofing on the surface of optical devices, can solve problems such as energy consumption, reduced light transmittance, blocking sight lines, etc., achieve good mechanical strength and stability, and reduce the decrease in light transmittance. , the effect of reducing collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

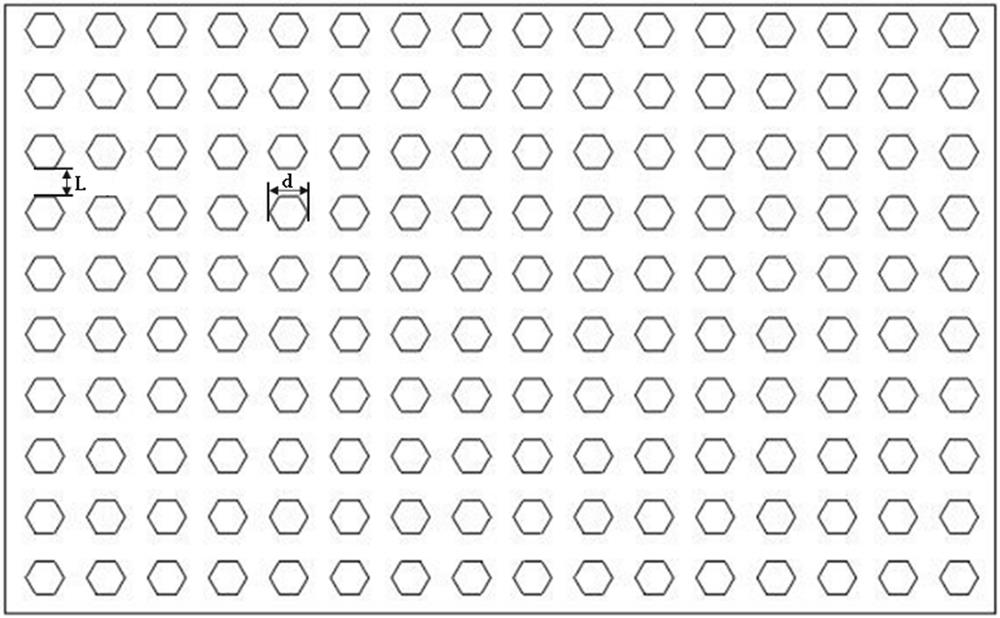

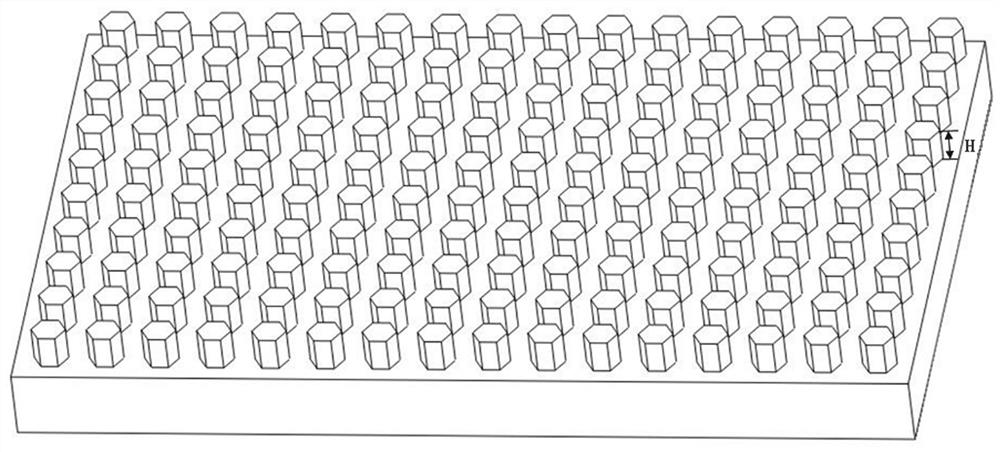

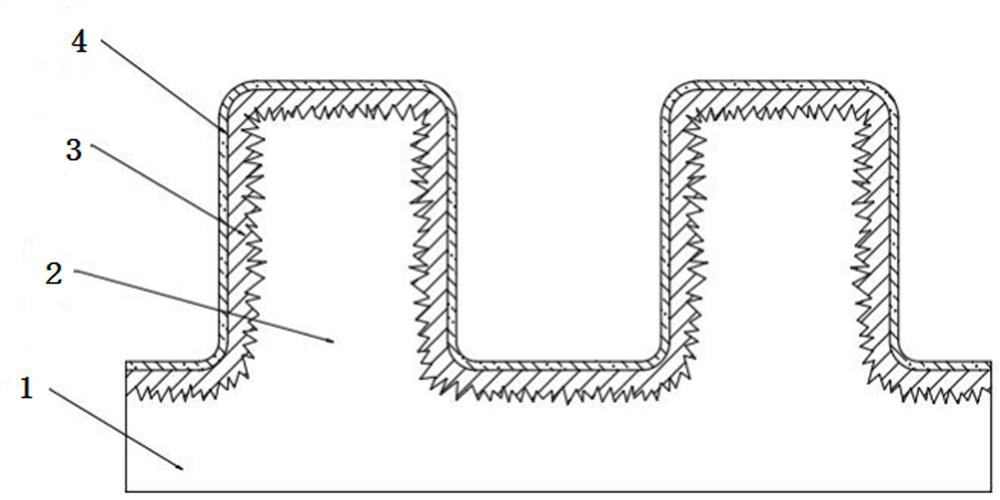

Embodiment 1

[0025] In this embodiment, the pulsed laser etching method is selected to prepare a micro-textured layer on the surface of the lens of the optical device, and the micro-textured units selected to be constructed are regular hexagonal columns, arranged in a regular arrangement, and the micro-textured units are set to the height: Cross-section size: pitch = 1.2:1:1, where the cross-section size is 6 μm; due to the immature development of the preparation technology at this stage, the surface of the prepared micro-textured layer has a rough structure, based on this, high-precision microscopes such as atomic force microscopes, Metallographic microscope and other observations and measurements, on the one hand, observe the surface morphology of the micro-textured layer, measure the data such as the width, depth, and spacing of the micro-textured unit for storage, and on the other hand, measure the roughness of the micro-textured layer, so that Design of subsequent coating thickness (co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com