Impurity salt heat storage material and preparation method thereof

A heat storage material and mixed salt technology, applied in the field of mixed salt heat storage material and its preparation, can solve the problems of uncertain mechanical strength of materials, guarantee, high heat storage density, etc., achieve rapid heat storage and heat storage density, improve sintering The effect of high stability and heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

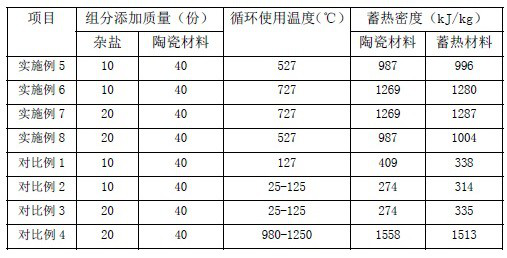

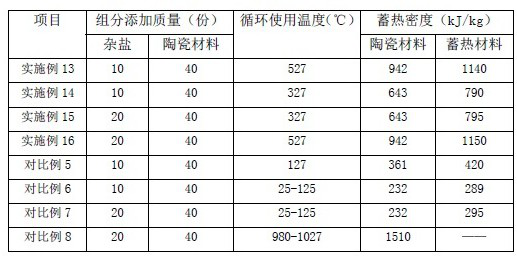

Examples

Embodiment 1

[0033] A preparation method of miscellaneous salt heat storage material, comprising the steps of:

[0034] (1) LiF-NaF miscellaneous salt is used, the mass ratio of LiF and NaF is 60:40, (the electrolytic aluminum waste residue mainly contains AlF 3 , NaF, LiF, CaO);

[0035] (2) The specific heat capacity of LiF-NaF heterosalt is: 1.83 kJ / (kg K), the melting point is: 925 K, the specific heat capacity of SiC ceramic is: 1.95 kJ / (kg K), the melting point is: 723 K; heat storage The recycling temperature of the material is 527°C, the added mass of LiF-NaF miscellaneous salt is 10 parts, and the added mass of SiC ceramic is 40 parts;

[0036] (3) Calcinate the LiF-NaF heterosalt to remove impurities, raise the temperature to 800°C at a rate of 10°C / min, and calcine at a constant temperature of 800°C for 5 hours;

[0037] (4) Mechanically mix the calcined LiF-NaF hetero-salt with SiC at high speed, after high temperature pre-oxidation at 1000°C for 10 minutes, temperature at 11...

Embodiment 2

[0039] The difference from Example 1 is that the added mass of miscellaneous salt is 20 parts.

Embodiment 3

[0041] The difference from Example 1 is that the cycle temperature of the heat storage material is 727°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com