Light-weight thin-wall wave-absorbing coating and preparation method thereof

A wave-absorbing coating and wave-absorbing material technology, applied in radiation-absorbing coatings, epoxy resin coatings, coatings, etc. The effect of excellent wave ability, improved wave absorbing ability, and excellent wave absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

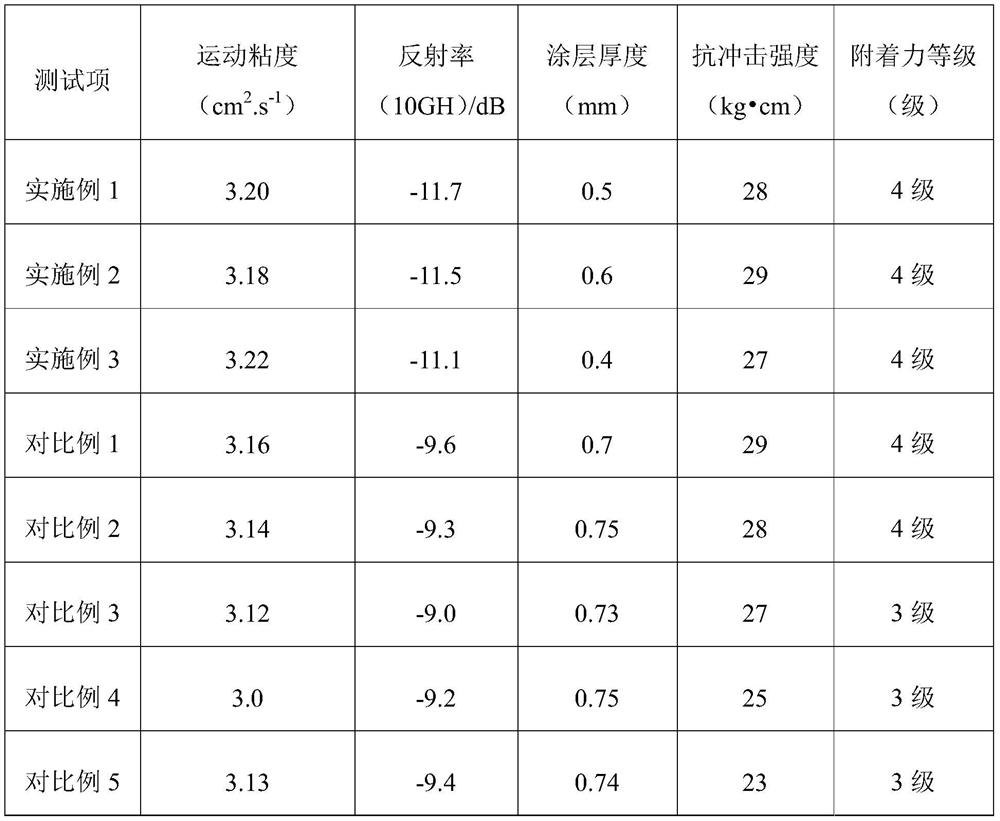

Examples

Embodiment 1

[0037] Embodiment 1 of the present invention provides a light-weight and thin-walled wave-absorbing coating on the one hand. In parts by weight, the preparation raw materials include: 60 parts of wave-absorbing material, 50 parts of high polymer matrix, 25 parts of organic solvent, organic silicon 0.2 parts of material, 6 parts of toughening agent;

[0038] The absorbing material includes carbon-based nanomaterials and metal nanopowders, and the mass ratio of the carbon-based nanomaterials and metal nanopowders is 1:1.2;

[0039] The carbon-based nanomaterial is a combination of single-walled carbon nanotubes and nano-white carbon black;

[0040] The mass ratio of the single-walled carbon nanotubes and nano-silica is 0.6:1;

[0041] The CAS number of the single-walled carbon nanotube is 308068-56-6, the model is A77912, the outer diameter is 2nm, and the length is 10nm, purchased from Shanghai Jizhi Biochemical Technology Co., Ltd.;

[0042] The article number of the nano wh...

Embodiment 2

[0058] Embodiment 2 of the present invention provides a light-weight and thin-walled wave-absorbing coating on the one hand. In parts by weight, the preparation raw materials include: 63 parts of wave-absorbing material, 59 parts of high polymer matrix, 30 parts of organic solvent, organic silicon 0.3 parts of material, 8 parts of toughening agent;

[0059] The absorbing material includes carbon-based nanomaterials and metal nanopowders, and the mass ratio of the carbon-based nanomaterials and metal nanopowders is 1:1.5;

[0060] The carbon-based nanomaterial is a combination of single-walled carbon nanotubes and nano-white carbon black;

[0061] The mass ratio of the single-walled carbon nanotubes and nano-silica is 0.8:1;

[0062] The CAS number of the single-walled carbon nanotube is 308068-56-6, the model is A77912, the outer diameter is 2nm, and the length is 10nm, purchased from Shanghai Jizhi Biochemical Technology Co., Ltd.;

[0063] The article number of the nano wh...

Embodiment 3

[0079]Embodiment 3 of the present invention provides a light-weight and thin-walled wave-absorbing coating on the one hand. In parts by weight, the preparation raw materials include: 52 parts of wave-absorbing material, 45 parts of high polymer matrix, 20 parts of organic solvent, organic silicon 0.1 parts of material, 4 parts of toughening agent;

[0080] The absorbing material includes carbon-based nanomaterials and metal nanopowders, and the mass ratio of the carbon-based nanomaterials and metal nanopowders is 1:1;

[0081] The carbon-based nanomaterial is a combination of single-walled carbon nanotubes and nano-white carbon black;

[0082] The mass ratio of the single-walled carbon nanotubes and nano-silica is 0.5:1;

[0083] The CAS number of the single-walled carbon nanotube is 308068-56-6, the model is A77912, the outer diameter is 2nm, and the length is 10nm, purchased from Shanghai Jizhi Biochemical Technology Co., Ltd.;

[0084] The article number of the nano white...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com