Al@MnO2 composite material and preparation method and application thereof

A composite material and reaction technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, and other chemical processes, to achieve the effects of less pollution, wider absorption frequency, and easier reaction control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Al@MnO proposed by the present invention 2 The method steps of composite material preparation are as follows:

[0042] S1: Pretreatment of Al powder: Add 2g of flake Al powder into a three-necked flask, then add 150ml of acetone, and react at 20°C for 20h. After the reaction is finished, suction filter, wash, and vacuum dry to obtain Al powder with a pure surface. The conditions for vacuum drying are: vacuum degree 0.06MPa, temperature 50°C, time 20h;

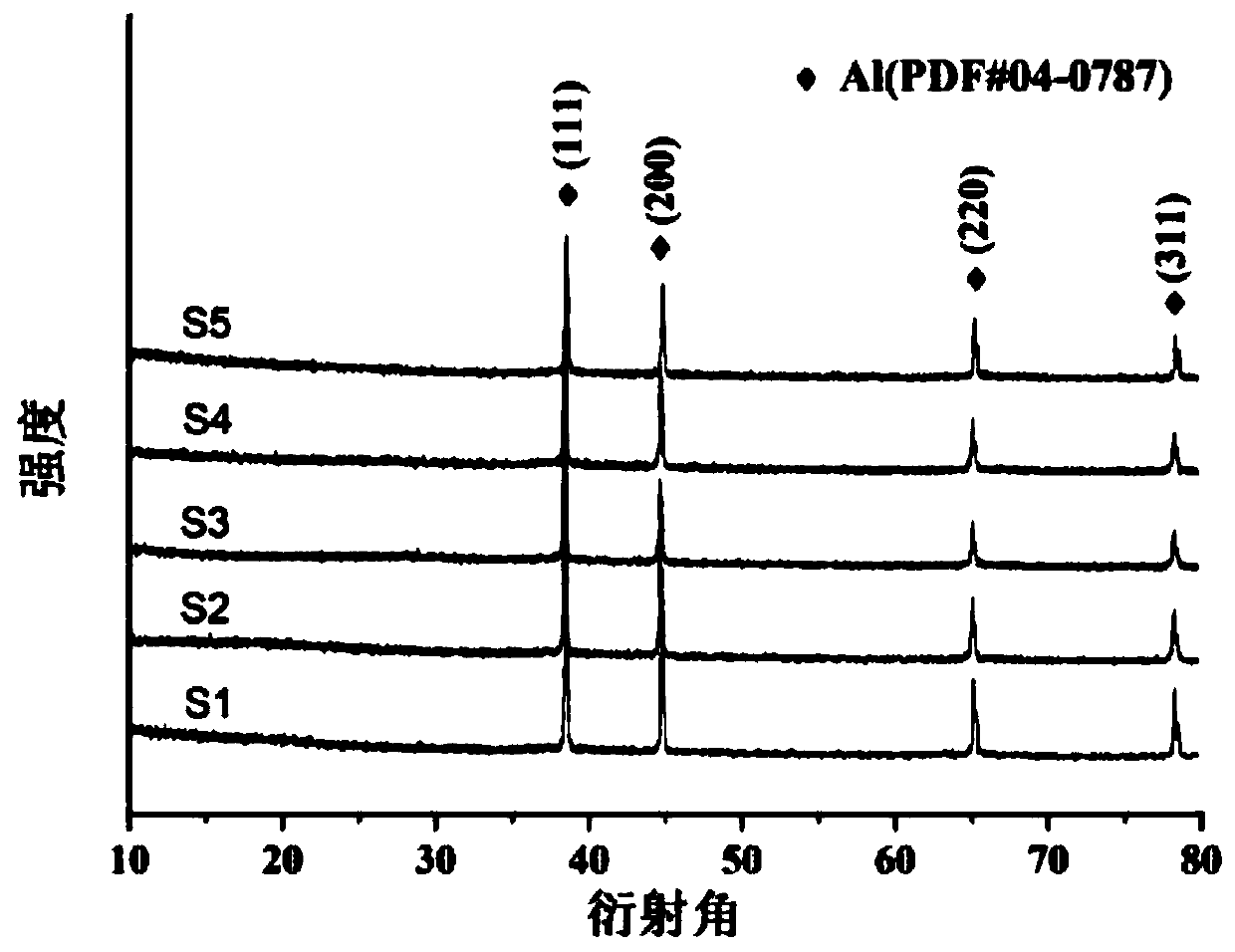

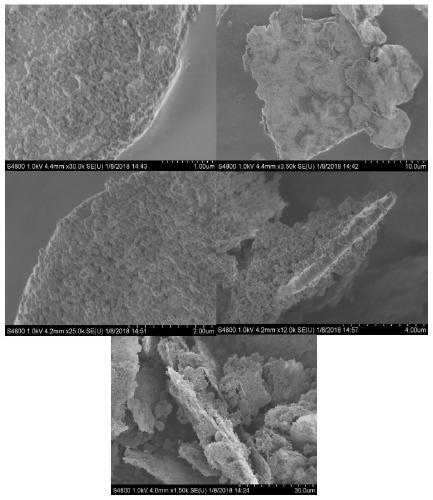

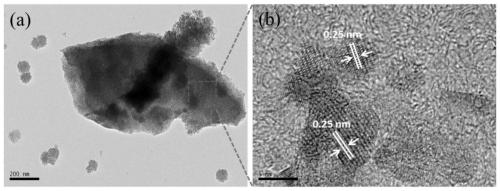

[0043] S2: Al@MnO 2 Synthesis of composite materials: Weigh 0.3g of Al powder treated in S1, add 60ml of distilled water into the container, and mix 0.1g of KMnO 4 Slowly add to the container, when the purple color of the solution is completely faded, filter it immediately, wash it with distilled water and absolute ethanol for 4 times, and dry the washed product in vacuum to obtain Al@MnO 2 For the composite material, the vacuum drying conditions are: vacuum degree 0.06Mpa, temperature 50°C, time 20h, magnetic stirrin...

Embodiment 2

[0045] Al@MnO proposed by the present invention 2 The method steps of composite material preparation are as follows:

[0046] S1: Pretreatment of Al powder: Add 5 g of flake Al powder into a three-neck flask, then add 150 ml of acetone, and react at 20° C. for 24 hours. After the reaction is finished, suction filter, wash, and vacuum dry to obtain Al powder with a pure surface. The conditions for vacuum drying are: vacuum degree 0.07MPa, temperature 60°C, time 24h;

[0047] S2: Al@MnO 2 Synthesis of composite materials: Weigh 0.5g of Al powder treated in S1, add 60ml of distilled water into the container, and mix 0.2g of KMnO 4 Slowly add to the container, when the purple color of the solution is completely faded, filter it immediately, wash it with distilled water and absolute ethanol for 4 times, and dry the washed product in vacuum to obtain Al@MnO 2 For the composite material, the vacuum drying conditions are: vacuum degree 0.07Mpa, temperature 60°C, time 24h, magnetic st...

Embodiment 3

[0049] Al@MnO proposed by the present invention 2 The method steps of composite material preparation are as follows:

[0050] S1: Pretreatment of Al powder: Add 5 g of flake Al powder into a three-neck flask, then add 150 ml of acetone, and react at 22° C. for 24 hours. After the reaction is finished, suction filter, wash, and vacuum dry to obtain Al powder with a pure surface. The conditions for vacuum drying are: vacuum degree 0.07MPa, temperature 60°C, time 24h;

[0051] S2: Al@MnO 2 Synthesis of composite materials: Weigh 0.5g of Al powder treated in S1, add 60ml of distilled water into the container, and mix 0.3g of KMnO 4 Slowly add to the container, when the purple color of the solution is completely faded, filter it immediately, wash it with distilled water and absolute ethanol for 4 times, and dry the washed product in vacuum to obtain Al@MnO 2 For the composite material, the vacuum drying conditions are: vacuum degree 0.07MPa, temperature 60°C, time 24h, and magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com