Alcoholysis-resistant heat-stable PPA composite material and preparation method thereof

A composite material and a stable technology, applied in the field of alcoholysis-resistant and heat-stabilized PPA composite materials and their preparation, can solve the problems of poor dimensional stability, poor thermal stability, poor hydrolysis resistance, etc., and achieve improved hydrolysis resistance, production technology and Simple equipment and good effect of interface adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

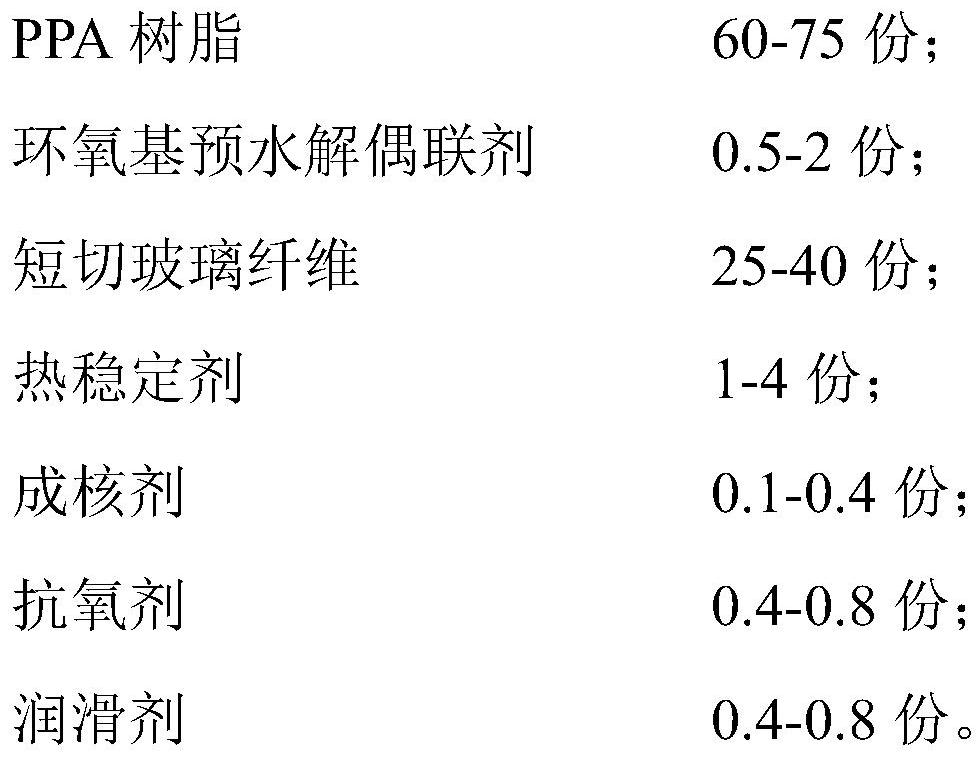

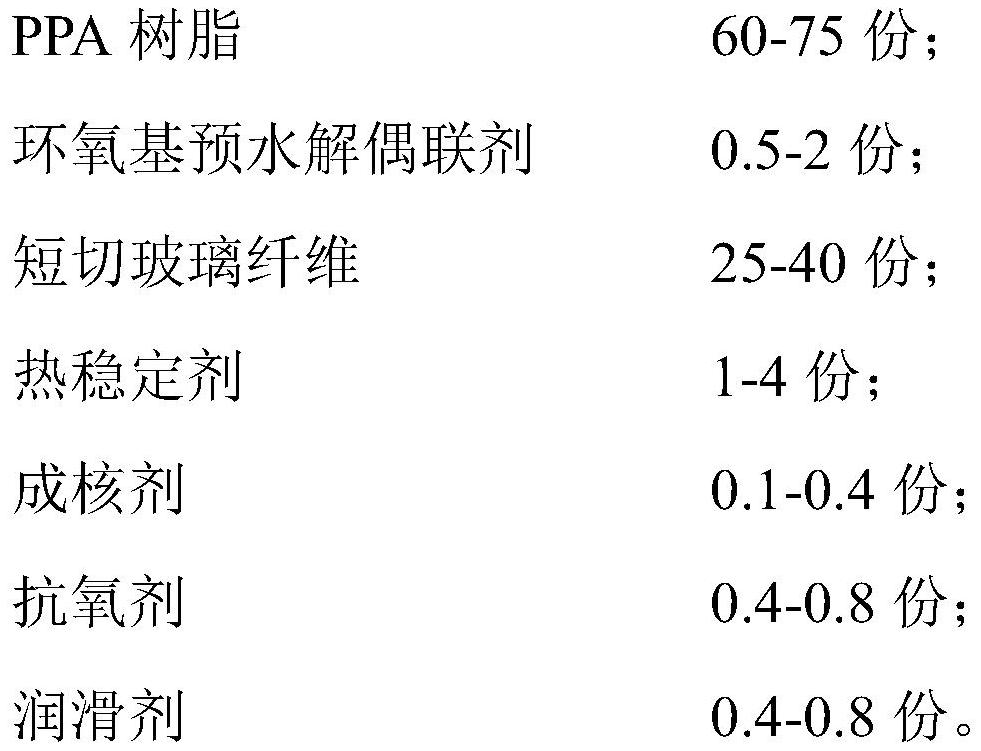

[0041] A kind of anti-alcoholysis heat stable PPA composite material, comprising by weight:

[0042]

[0043] Put the above-mentioned materials except chopped glass fiber and epoxy-based prehydrolysis coupling agent into a high-speed mixer and mix evenly (mixing for 3 minutes, high-speed mixer speed 500RPM), and then put the mixed material into the extruder The main discharge barrel of the machine is granulated through the extruder. During the extrusion process, 30 parts of chopped fibers are added by side feeding, and 0.5 parts of epoxy-based pre-hydrolysis coupling agent is added through a micro pump to keep the vacuum open. The temperature of each temperature zone of the extruder is: zone 1 150°C, zone 2 320°C, zone 3 320°C, zone 4 320°C, zone 5 310°C, zone 6 300°C, zone 7 290°C, zone 8 290°C, The ninth zone is 290°C, the tenth zone is 290°C, the eleventh zone is 300°C, the head is 310°C, and the speed of the extruder is 400RPM.

[0044] The PPA resin is polyhexamethyle...

Embodiment 2

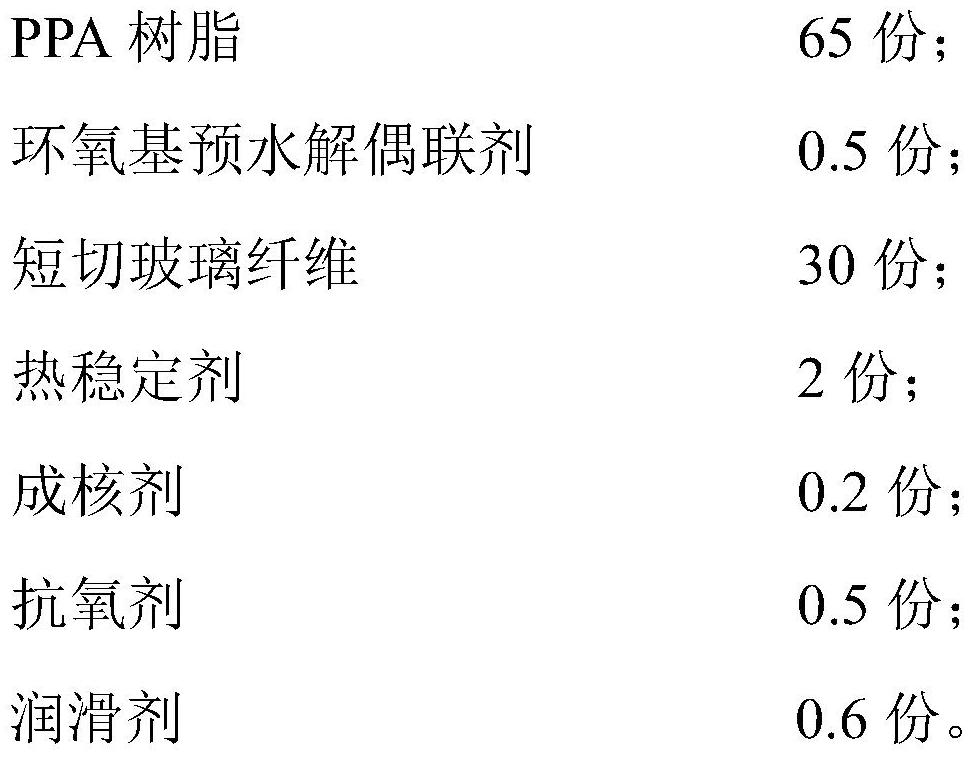

[0046] The present embodiment differs from Example 1 in that: first take the following materials in parts by weight:

[0047]

[0048] Put the above-mentioned materials except chopped glass fiber and epoxy-based prehydrolysis coupling agent into a high-speed mixer and mix evenly (mixing for 3 minutes, high-speed mixer speed 500RPM), and then put the mixed material into the extruder The main discharge barrel of the machine is granulated through the extruder. During the extrusion process, 30 parts of chopped fibers are added through side feeding, and 1 part of epoxy-based pre-hydrolysis coupling agent is added through a micro pump to keep the vacuum open. The temperature of each temperature zone of the extruder is: zone 1 150°C, zone 2 320°C, zone 3 320°C, zone 4 320°C, zone 5 310°C, zone 6 300°C, zone 7 290°C, zone 8 290°C, The ninth zone is 290°C, the tenth zone is 290°C, the eleventh zone is 300°C, the head is 310°C, and the speed of the extruder is 400RPM.

[0049] The P...

Embodiment 3

[0051] The present embodiment differs from Example 1 in that: first take the following materials in parts by weight:

[0052]

[0053] Put the above-mentioned materials except chopped glass fiber and epoxy-based prehydrolysis coupling agent into a high-speed mixer and mix evenly (mixing for 3 minutes, high-speed mixer speed 500RPM), and then put the mixed material into the extruder The main discharge barrel of the machine is granulated through the extruder. During the extrusion process, 40 parts of chopped fibers are added through side feeding, and 1 part of epoxy-based pre-hydrolysis coupling agent is added through a micro pump to keep the vacuum open. The temperature of each temperature zone of the extruder is: zone 1 150°C, zone 2 320°C, zone 3 320°C, zone 4 320°C, zone 5 310°C, zone 6 300°C, zone 7 290°C, zone 8 290°C, The ninth zone is 290°C, the tenth zone is 290°C, the eleventh zone is 300°C, the head is 310°C, and the speed of the extruder is 400RPM.

[0054] The P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com