Antibacterial nylon 6 containing guanidyl group and preparation method thereof

A nylon and group technology, applied in the field of antibacterial material preparation, can solve the problems of poor heat resistance and inability to meet the processing conditions of thermoplastic materials, and achieve the effects of simple and convenient operation, prevention of bacterial drug resistance, and lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

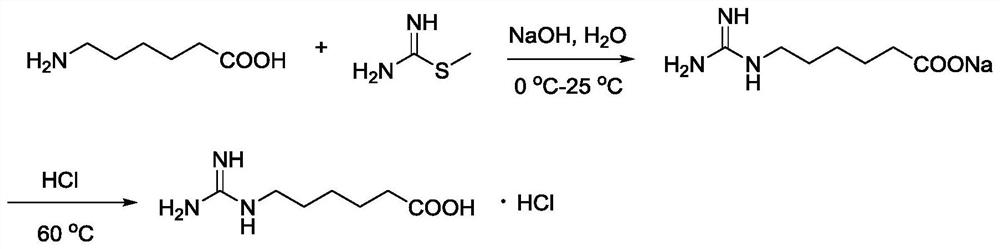

preparation example Construction

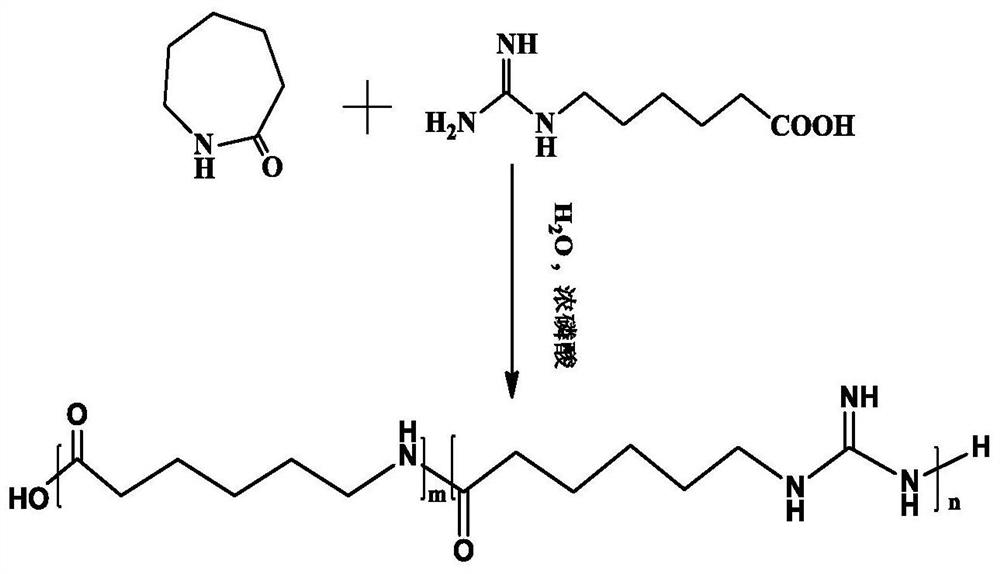

[0039]Specifically, the preparation method comprises: adding caprolactam, deionized water, concentrated phosphoric acid and 6-guanidinohexanoic acid to 100% by mass percentage: (1-2%): (1-3%): (0.8-5.0 %) into the reaction device, heat up in a nitrogen atmosphere and react for a preset time, then vacuumize to carry out a reduced-pressure compression polymerization reaction, and finally end the reaction, pour the melt out and cool it to shape, and the antibacterial nylon 6 is obtained.

[0040] The preset time for the temperature rise reaction includes: under the reflux condition of the condenser tube, after the preset time of reaction at the stirring speed of 120-150r / min and 250-260°C, the temperature of the polymerization reaction system is raised to 270-280°C, and the stirring speed is Adjust it to 250-300r / min, change the condenser tube to a vacuum device, and turn off the nitrogen.

[0041] The preset reaction time is preferably 3-4 hours.

[0042] The time for the reduc...

Embodiment 1

[0045] A kind of antibacterial nylon 6 containing guanidine group, prepared through the following steps:

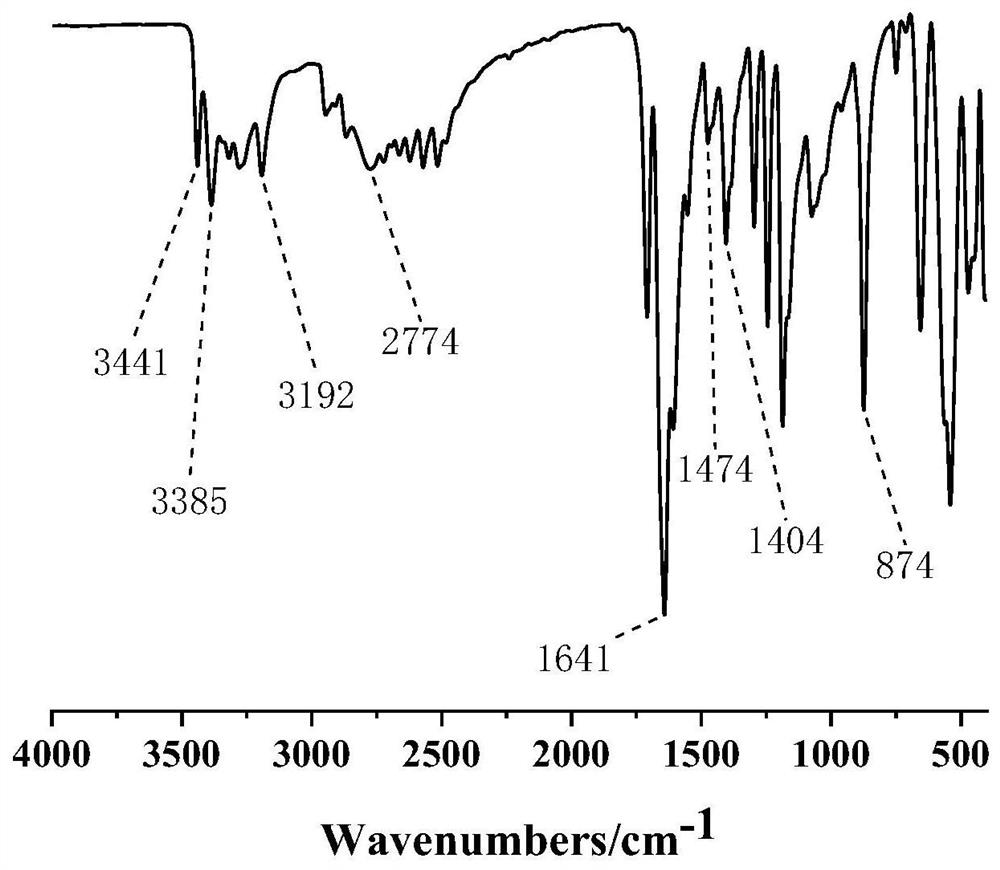

[0046] After setting up the reaction device, feed nitrogen into the device as a protective gas, so that the reaction is in a continuous nitrogen flow. After ventilating for 10 to 15 minutes, add the medicines weighed in proportion to the device, caprolactam, deionized water, concentrated phosphoric acid and 6 -Guanidinohexanoic acid (infrared spectrum such as figure 2 Shown) the mass percent is 100%:1.5%:2%:1%. The ring-opening reaction of caprolactam is carried out under the conditions of reflux in the condenser tube, stirring (120-150 r / min) and reaction temperature (250-260° C.). After 3-4 hours, raise the temperature of the polymerization reaction system (270-280°C), increase the stirring speed (250-300r / min), change the condenser tube to a vacuum device, turn off the nitrogen, and vacuum the reaction system to decompress The polycondensation reaction takes 10 to 3...

Embodiment 2-3

[0053] An antibacterial nylon 6 containing a guanidino group, the difference compared with Example 1 is that the amount of 6-guanidinohexanoic acid added is as shown in Table 1. Others are substantially the same as in Embodiment 1, and will not be repeated here.

[0054] Preparation conditions and bactericidal rate of table 1 embodiment 1-3 and comparative examples

[0055]

[0056] It can be seen from Table 1 that with the increase of the dosage of 6-guanidine hexanoic acid, the sterilization rate of antibacterial nylon gradually increased, but due to the access of 6-guanidine hexanoic acid, the intrinsic viscosity of antibacterial nylon was affected to a certain extent. The more the amount of 6-guanidinohexanoic acid is used, the lower the intrinsic viscosity and the lower the tensile strength, but it can still meet the application requirements. If 6-guanidinohexanoic acid is not added to the polymerization system, the resulting nylon has higher intrinsic viscosity and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com