Biodegradable copolyester as well as preparation method and application thereof

A biodegradable and copolyester technology, which is applied in the field of polyester plastics, can solve the problems of complex preparation steps and affecting product quality, and achieve the effects of easy mixing, guaranteed performance, and sufficient polycondensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

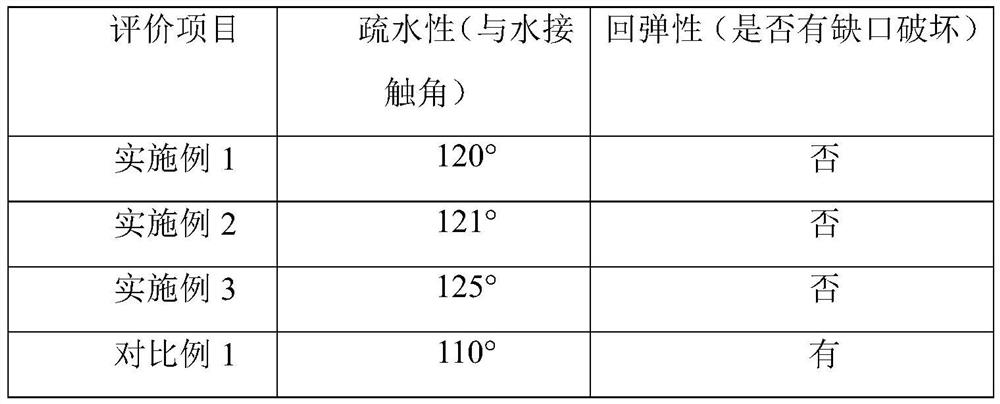

[0048] Example 1 A biodegradable copolyester disclosed in this example is composed of the following raw materials in percentage by weight: 40% dihydric alcohol, 7% dimer fatty acid, 15.99% aromatic dibasic acid, 37% aliphatic dibasic acid %, titanate 0.01%; wherein, the molecular formula of the dimer fatty acid is C 36 h 64 o 4 , whose structural formula includes a six-membered ring, on which at least two dibasic acid branch chains are grafted.

[0049] The effect of the above-mentioned biodegradable copolyester: the biodegradable polymer composed of the above-mentioned raw materials has good hydrophobicity and resilience, and can be applied to mulch.

[0050] In the present embodiment, the structural formula of the dimerized fatty acid is

[0051] R1, R2, R3 and R4 are alkyl groups.

[0052] In this embodiment, the titanate is one or a mixture of tetrabutyl titanate and tetraisopropyl titanate.

[0053] In this embodiment, the dihydric alcohol contains 8% by weight of ...

Embodiment 2

[0064] A biodegradable copolyester disclosed in this embodiment is composed of the following raw materials in percentage by weight, 60% of glycol, 0.05% of dimer fatty acid, 9% of aromatic dibasic acid, 30.85% of aliphatic dibasic acid, titanium Ester 0.1%; Wherein, the molecular formula of the dimer fatty acid is C 36 h 64 o 4 , whose structural formula includes a six-membered ring, on which at least two dibasic acid branch chains are grafted.

[0065] The effect of the above-mentioned biodegradable copolyester: the biodegradable polymer composed of the above-mentioned raw materials has good hydrophobicity and resilience, and can be applied to mulch.

[0066] In the present embodiment, the structural formula of the dimerized fatty acid is

[0067] R1, R2, R3 and R4 are aryl groups.

[0068] In this embodiment, the titanate is one or a mixture of tetrabutyl titanate and tetraisopropyl titanate.

[0069] In this embodiment, the dihydric alcohol contains 8% by weight of a...

Embodiment 3

[0080] A biodegradable copolyester disclosed in this embodiment is composed of the following raw materials in percentage by weight, 50% of glycol, 3.95% of dimer fatty acid, 37% of aromatic dibasic acid, 9% of aliphatic dibasic acid, titanium Ester 0.05%; wherein, the molecular formula of the dimer fatty acid is C 36 h 64 o 4 , whose structural formula includes a six-membered ring, on which at least two dibasic acid branch chains are grafted.

[0081] The effect of the above-mentioned biodegradable copolyester: the biodegradable polymer composed of the above-mentioned raw materials has good hydrophobicity and resilience, and can be applied to mulch.

[0082] In the present embodiment, the structural formula of the dimerized fatty acid is

[0083] A mixture of R1, R2, R3 and R4 are alkyl and aryl.

[0084] In this embodiment, the titanate is one or a mixture of tetrabutyl titanate and tetraisopropyl titanate.

[0085] In this embodiment, the dihydric alcohol contains 6% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com