Preparation method of silicate aqueous solution

A water solution and silicate technology, applied in the direction of silicate, alkali metal silicate, chemical instruments and methods, etc., to achieve good economic and social benefits, flexible and controllable product modulus, and simplify the raw material refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of described silicate aqueous solution, comprises the following steps:

[0031] (1) get fluosilicic acid and calcium carbonate normal temperature reaction, the clear filtrate obtained by solid-liquid separation after the reaction, use this clear filtrate as silicon source solution;

[0032] This step involves a chemical reaction:

[0033] h 2 SiF 6 +3CaCO 3 =3CaF 2 ↓+3CO 2 ↑+SiO2 2 (aq)

[0034] The obtained silicon dioxide is in a metastable solution state, has high activity, and is easy to polymerize with each other to form a colloid, or react with an alkali metal ion to form a salt.

[0035] (2) Mix alkali metal hydroxide AOH (AOH=NaOH or KOH or LiOH) with deionized water to prepare an alkali solution with a concentration of 10wt%-wt20%.

[0036] The solid particle raw material of alkali metal hydroxide can be directly used, but a white solid jelly will be generated in the initial stage of the reaction, and a colorless and transparent p...

Embodiment 1

[0053] A preparation method of aqueous sodium silicate solution, comprising the following steps:

[0054] (1) Weigh 12033g of fluosilicic acid solution with a concentration of 14.37wt% and react with 8340g of calcium carbonate suspension with a concentration of 43.21wt% for 20 minutes, then separate the solid from the liquid through a plate and frame filter, clean the filter cake with 2100g of clear water, and combine the washings into the filtrate to obtain clear filtrate 15636g, SiO in the filtrate 2 wt% = 4.12%.

[0055] (2) Weigh 418g of the prepared 20wt% NaOH solution.

[0056](3) Start the reactor to stir, then get 7000g of the filtrate of step (1) and the NaOH solution of step (2) into the reactor continuously within 5 minutes simultaneously, then continue to react for 30 minutes to obtain a clear and transparent solution. In this step, lye can be added to the filtrate, or the filtrate can be added to the lye to react, but it takes a long reaction time to eliminate t...

Embodiment 2

[0071] A kind of preparation method of sodium silicate aqueous solution

[0072] In this embodiment, the amount of NaOH solution is changed to 874g, and the rest are the same as in Example 1.

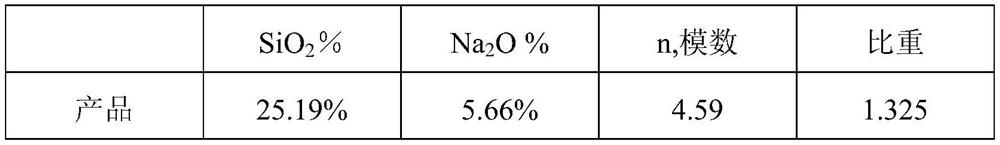

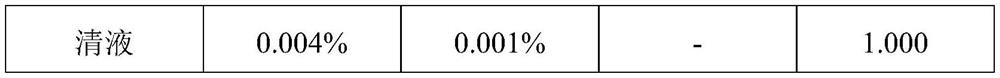

[0073] The membrane is concentrated until the specific gravity of the remaining solution in the raw material tank increases to 1.478g / cm 3 When, stop concentrating, obtain clear liquid 6739g simultaneously. According to the analysis of GB / T4209-2008 "Industrial Sodium Silicate", the indicators of the obtained sodium silicate product and clear liquid are as follows.

[0074] Table 2 embodiment 2 gained product analysis index

[0075] SiO 2 %

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com