Preparation method and application of nitrogen and oxygen co-doped carbon material containing 3d metal single atom

A carbon material and co-doping technology, which is applied in the preparation/purification of carbon, electrodes, electrolysis process, etc., can solve the problems of poor selectivity and activity, complex preparation methods, etc., to achieve uniform morphology, good repeatability, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a carbon material containing cobalt single atoms and nitrogen and oxygen co-doped, comprising the following steps:

[0042] (1) Get 1g ethylenediaminetetraacetic acid, 2g potassium hydroxide, 0.1225g cobalt acetate tetrahydrate, and grind evenly;

[0043] (2) Transfer the reagents in step (1) to the ark, then transfer to a tube furnace, and calcine in an argon atmosphere at a heating rate of 5°C / min, raise the temperature to 700°C, and calcine for 2 hours;

[0044] (3) The sample calcined in the step (2) is taken out, centrifugally washed three times with 0.05mol / L hydrochloric acid, three times centrifugally washed with deionized water;

[0045] (4) Put the sample in step (3) into a vacuum oven to dry for 10 h.

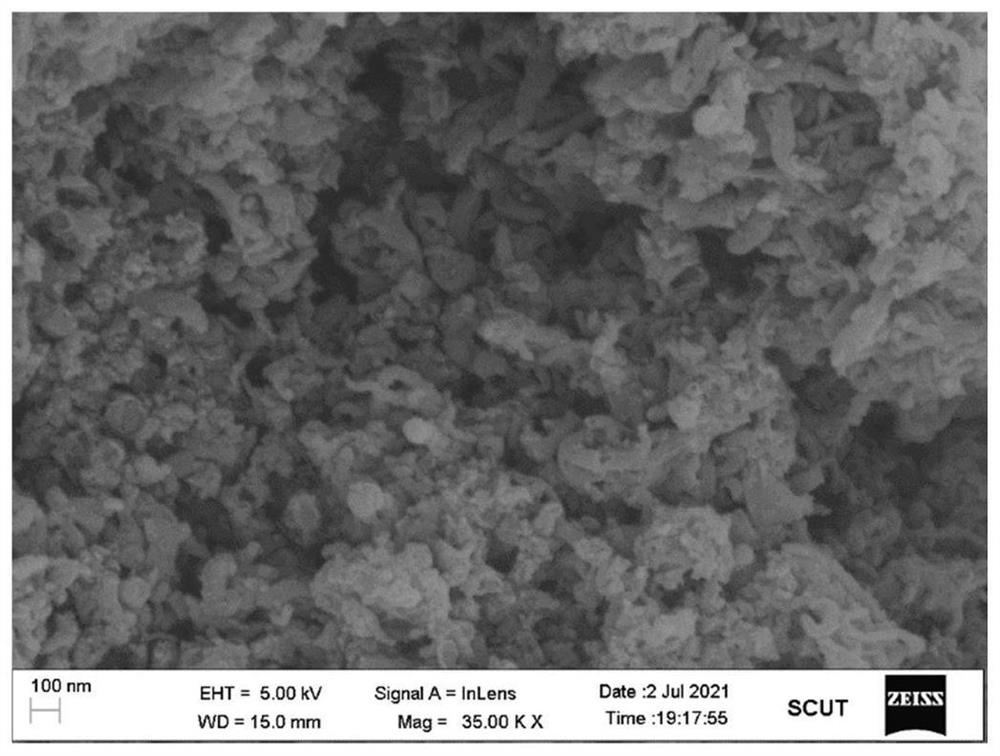

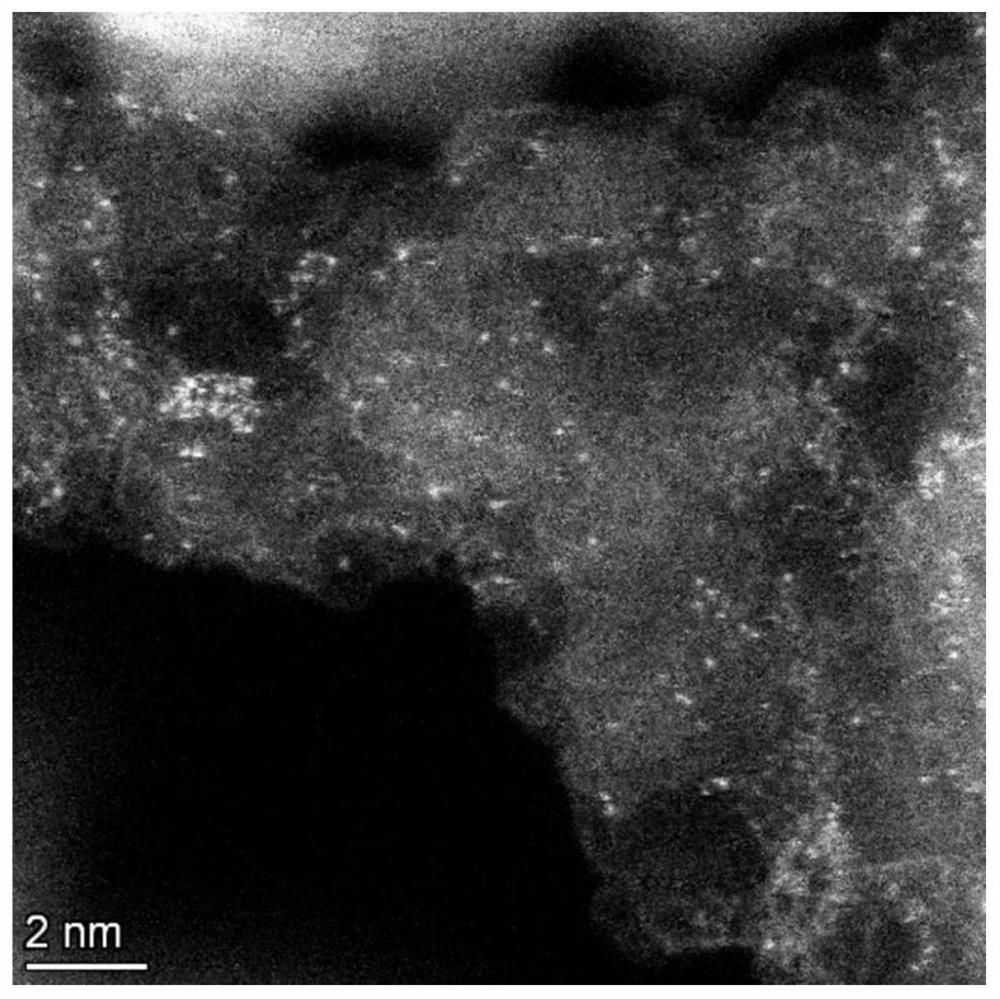

[0046] The SEM of the carbon material containing cobalt single atom and nitrogen, oxygen co-doped that adopts embodiment 1 preparation is as figure 1 As shown, it can be seen from the figure that the carbon material is distributed in a...

Embodiment 2

[0048] A method for preparing a carbon material containing cobalt single atoms and nitrogen and oxygen co-doped, comprising the following steps:

[0049] (1) Get 2g ethylenediaminetetraacetic acid, 4g potassium hydroxide, 0.245g cobalt acetate tetrahydrate, and grind evenly;

[0050] (2) Transfer the reagents in step (1) to the ark, then transfer to a tube furnace, and calcinate in an argon atmosphere at a heating rate of 5°C / min, raise the temperature to 700°C, and calcinate for 2 hours;

[0051] (3) The sample calcined in the step (2) is taken out, centrifugally washed three times with 0.05mol / L hydrochloric acid, three times centrifugally washed with deionized water;

[0052] (4) Put the sample in step (3) into a vacuum oven to dry for 10 h.

Embodiment 3

[0054] A method for preparing a carbon material containing iron single atoms and nitrogen and oxygen co-doped, comprising the following steps:

[0055] (1) Get 1g ethylenediaminetetraacetic acid, 2g potassium hydroxide, 0.2g iron acetylacetonate, grind evenly;

[0056](2) Transfer the reagents in step (1) to the ark, then transfer to a tube furnace, and calcine in an argon atmosphere at a heating rate of 5°C / min, raise the temperature to 700°C, and calcine for 2 hours;

[0057] (3) The sample calcined in the step (2) is taken out, centrifugally washed three times with 0.05mol / L hydrochloric acid, three times centrifugally washed with deionized water;

[0058] (4) Put the sample in step (3) into a vacuum oven to dry for 10 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com