High-pressure steaming oven and integrated cooker using same

A high-pressure steaming and oven technology, which is applied in the field of steam heating, can solve the problems of uneven inner tank temperature, long heating time of food, and excessive nutrient loss, and achieve the effects of shortening heating time, improving safety in use, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

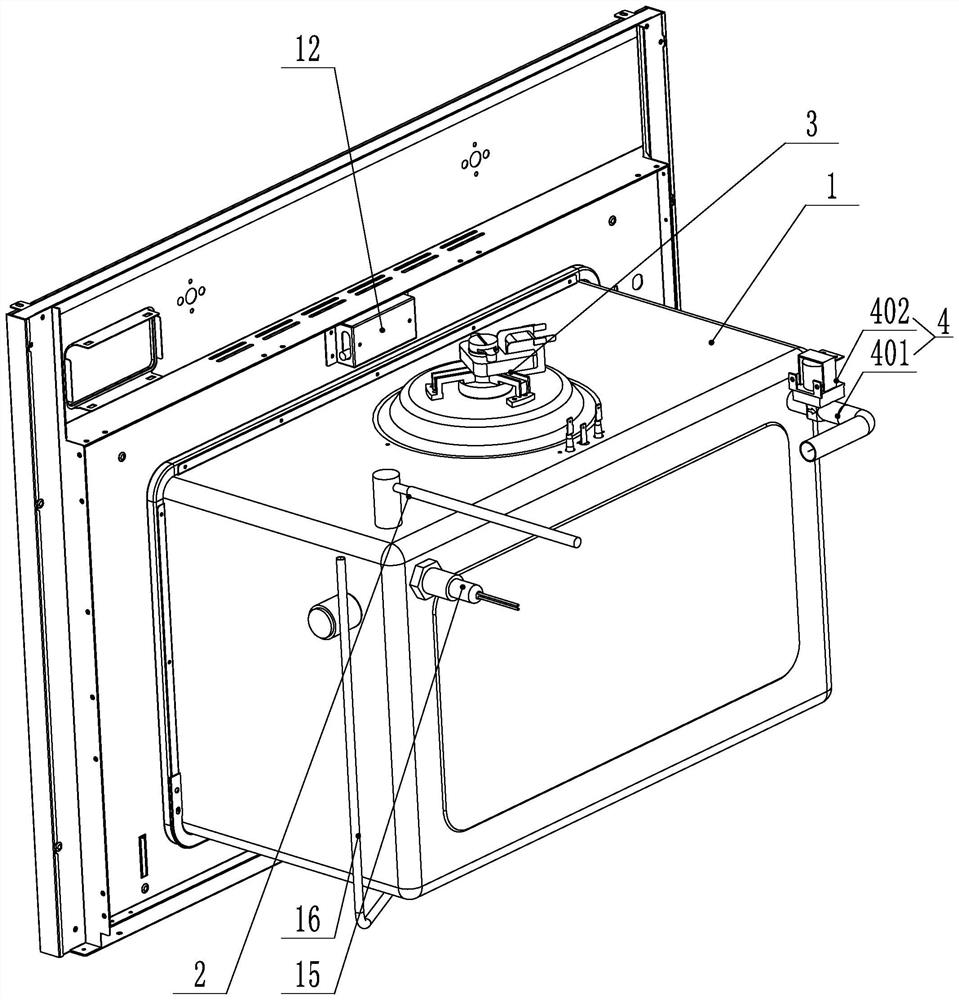

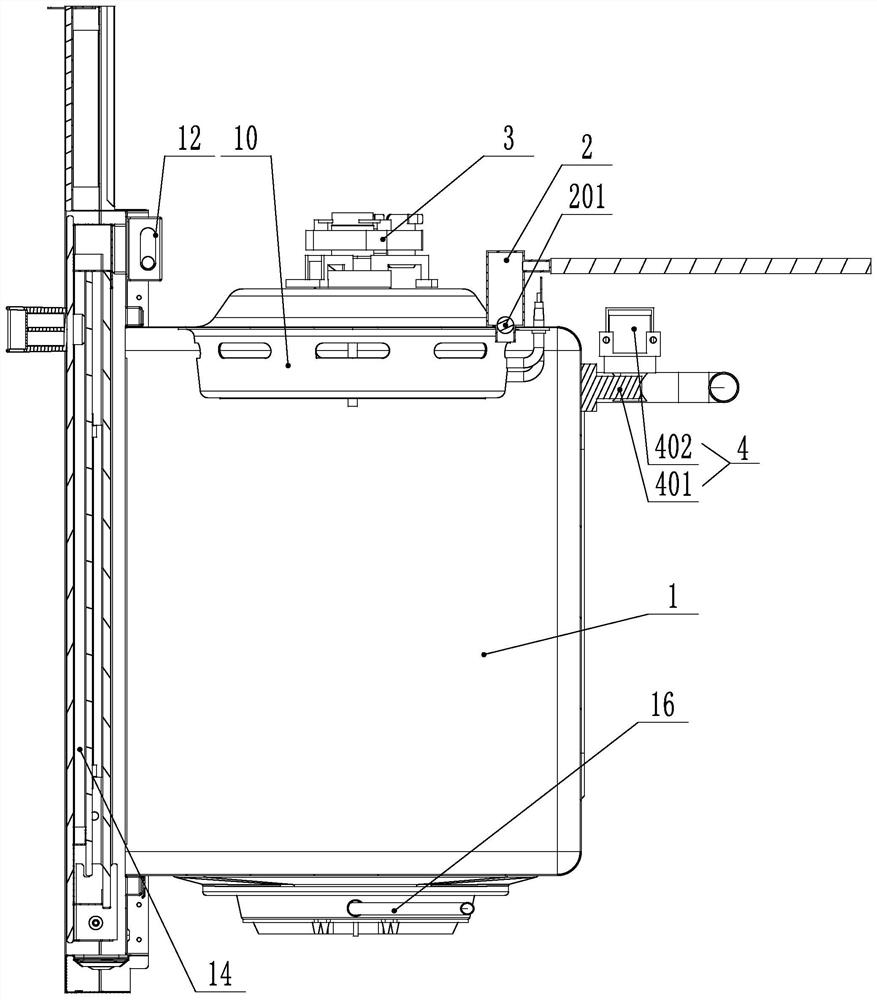

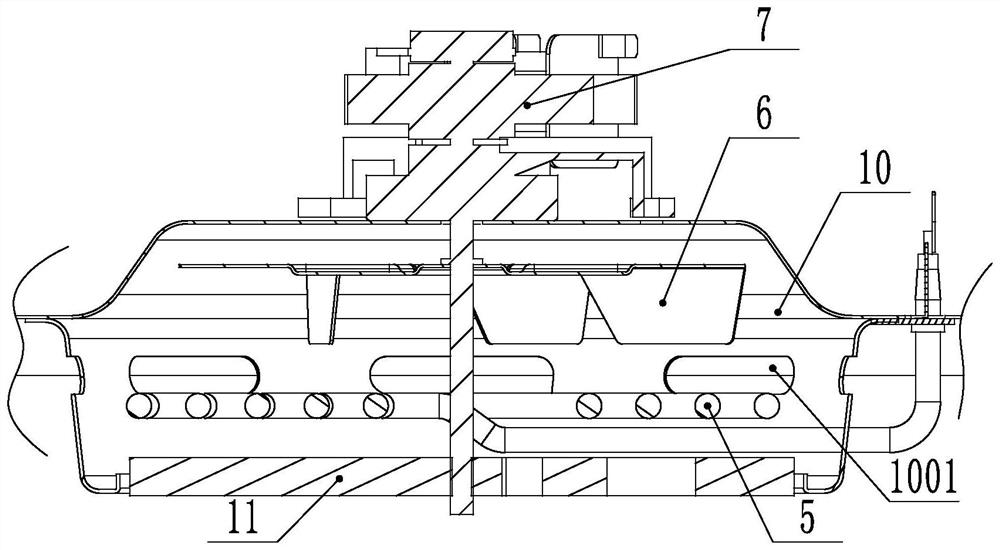

[0037] Such as Figure 1-2 As shown, a high-pressure steam oven includes an inner container 1, a steam generator, and a controller; it is characterized in that it also includes a pressure relief valve 2, an exhaust valve 4, and an electric heating assembly 3 located at the top of the inner container 1; The assembly 3 includes an electric heating tube 5, a fan blade 6 positioned above the electric heating tube 5, a motor 7 for driving the fan blade 6 to work, and a ventilation cover 10 positioned outside the electric heating tube 5 and the fan blade 6; the peripheral side of the ventilation cover 10 is provided with A plurality of ventilation holes 1001, the position of the ventilation holes 1001 is higher than the electric heating tube 5; the air inlets of the pressure relief valve 2 and the exhaust valve 4 are connected with the inner cavity of the inner tank 1; the pressure relief valve 2 is provided with a pressure limiting member, when When the pressure of the inner tank 1...

Embodiment 2

[0041] Similarities with Embodiment 1 will not be repeated, and the difference lies in.

[0042] In order to ensure that the steam pressure of the inner bag 1 is maintained within a set range, the steam generator is connected to the water tank by a water pipe 16, and the water pipe 16 is provided with a water pump to carry out high-pressure water supply. When the pressure of the inner tank 1 rises, the water in the water tank cannot enter the steam generator by gravity alone, and the water needs to be delivered by the water pump to ensure that the steam pressure of the inner tank 1 is maintained within the set range. After the water pump is set, the setting position of the water tank will be more flexible, and it does not have to be placed on the top of the inner tank 1, and the steam generator is supplied with water by the dead weight of the water.

[0043] In order to realize precise control, the water tank or water pipe 16 is provided with a water pressure sensor for detect...

Embodiment 3

[0045] The similarities with Embodiment 1 will not be described in detail. The difference is that in order to realize the reliability of locking the door, the inner tank 1 is provided with a locking device matching the door body 14, and the locking device is a magnetic suction locking device 12. The magnetic locking device 12 is connected with the controller. The magnetic locking device 12 can be arranged on multiple sides of the door frame. The magnetic suction locking device 12 is convenient to control, and is less restricted than structural parts such as bolt limiters. The magnetic suction surface of the magnetic suction locking device 12 can be larger, which is conducive to improving the locking force and avoiding excessive air pressure at the inner tank 1. Big, and the situation that causes door body 14 to be pushed back takes place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com