Axial ultrasonic through-flow fan serial configuration and serial configuration optimization method

A supersonic, axial technology, used in design optimization/simulation, components of pumping devices for elastic fluids, instruments, etc., can solve the problem of high Mach number of blade incoming flow and weaken strong torsional vibration mode flutter. , flutter instability and other problems, to achieve the effect of reducing the total pneumatic pressure loss, avoiding flutter instability, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

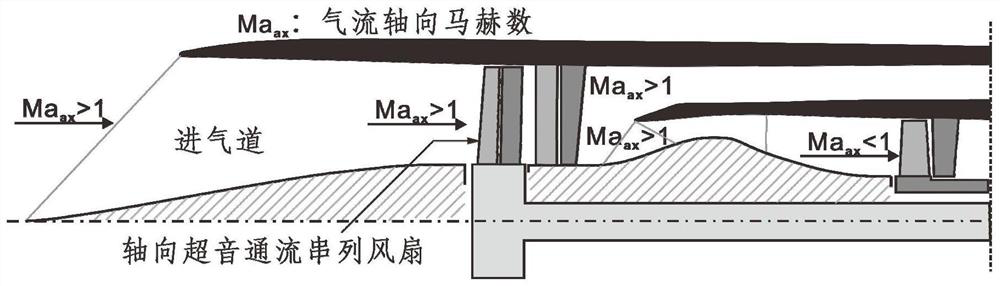

[0035] Such as Figure 1 ~ Figure 4 As shown, the configuration design method of an axial ultrasonic ventilation fan disclosed in this embodiment includes the following steps:

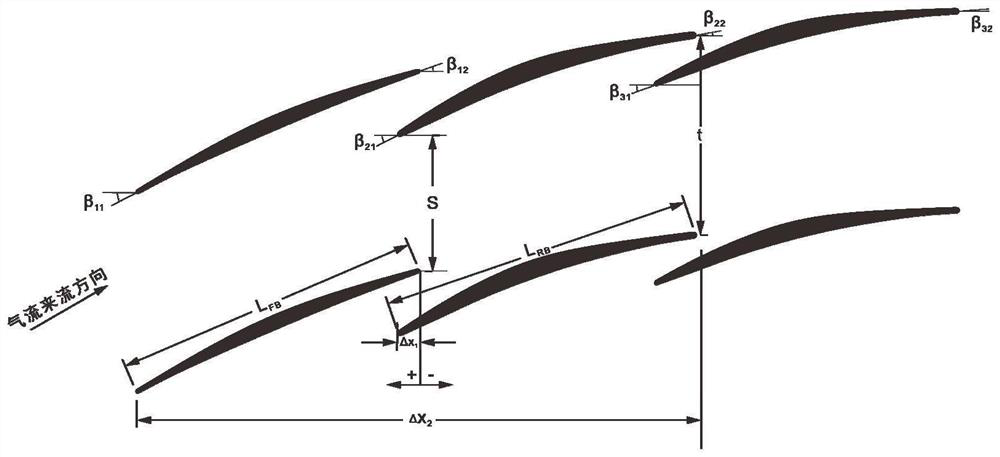

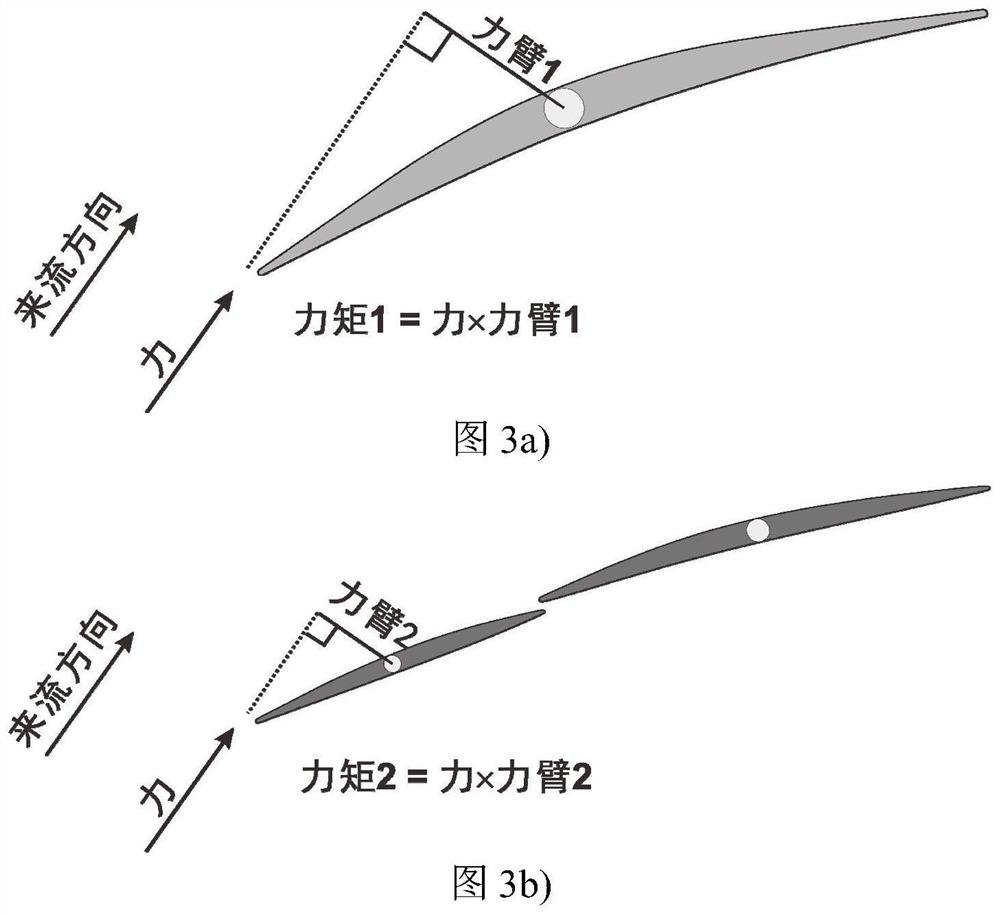

[0036] Step 1: Carry out tandem design on the blades of the single-row axial supersonic through-flow fan, and complete the geometric modeling of the preliminary tandem scheme. The definition of geometric parameters and the geometric model are as follows: figure 2 and image 3 As shown in b), the preliminary tandem geometric and aerodynamic parameters are shown in Table 1.

[0037] Table 1 Geometric and aerodynamic parameters of preliminary tandem design

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com