Method for depositing activated film on copper surface by adopting reverse displacement deposition liquid

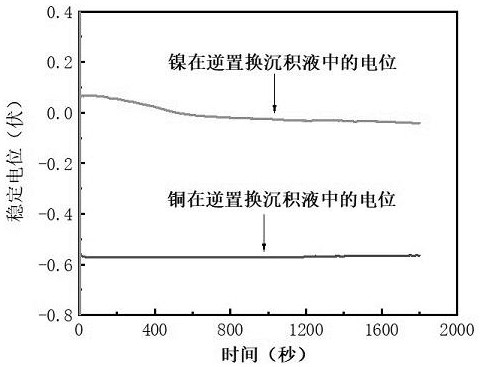

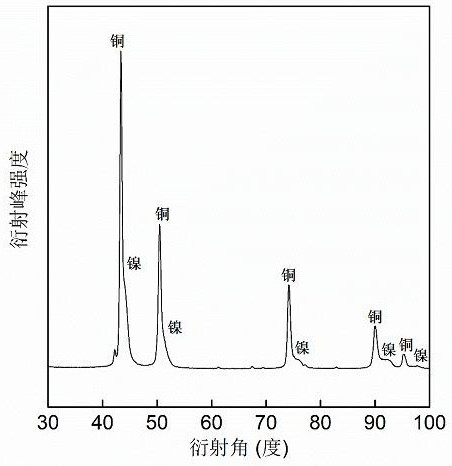

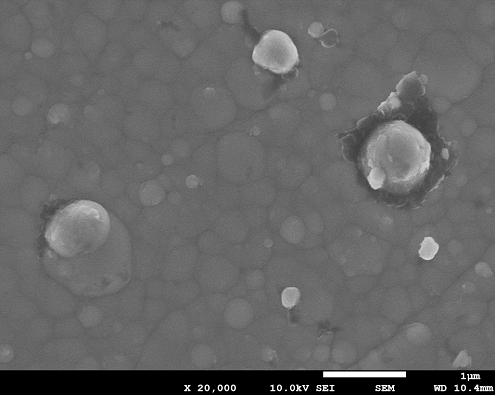

A technology for depositing liquid and copper surfaces, applied in liquid chemical plating, final product manufacturing, coating, etc., can solve the problems of unfavorable chemical nickel plating and phosphorus, and achieve the effects of reduced activation cost, excellent corrosion resistance, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A method for depositing an activated film on a copper surface using a reverse displacement deposition solution, comprising the following steps:

[0030] (1) Immerse the copper substrate in an alkaline chemical degreasing solution at 35°C and stir for 5 minutes; after fully washing the copper substrate treated with alkaline chemical degreasing with water, immerse it in an acidic etching solution at 25°C for 1.5 minutes; then take it out and Rinse sufficiently with water to obtain a cleaned copper substrate.

[0031] Among them: Alkaline chemical degreasing liquid is prepared by dissolving 18g of sodium hydroxide, 55g of sodium carbonate, and 6g of sodium silicate in 1L of pure water.

[0032] The acidic etching solution is prepared by dissolving 12g of sulfuric acid and 55g of sodium persulfate in 1L of pure water.

[0033] ⑵ Preparation of reverse displacement deposition solution:

[0034] Add 7g of nickel chloride and 1900g of sodium iodide into 1L of pu...

Embodiment 2

[0039] Embodiment 2 A method for depositing an activated film on a copper surface using a reverse displacement deposition solution, comprising the following steps:

[0040] (1) Immerse the copper substrate in an alkaline chemical degreasing solution at 62°C and stir for 10 minutes; after fully cleaning the copper substrate treated with alkaline chemical degreasing with water, immerse it in an acidic etching solution at 30°C for 5 minutes; then take it out and Rinse sufficiently with water to obtain a cleaned copper substrate.

[0041] Among them: Alkaline chemical degreasing liquid is prepared by dissolving 24g of sodium hydroxide, 95g of sodium carbonate, and 10g of sodium silicate in 1L of pure water.

[0042] The acidic etching solution is prepared by dissolving 49g of sulfuric acid and 98g of sodium persulfate in 1L of pure water.

[0043] ⑵ Preparation of reverse displacement deposition solution:

[0044] Add 95g of nickel sulfate and 550g of potassium iodide into 1L of...

Embodiment 3

[0046] Embodiment 3 A method for depositing an activated film on a copper surface using a reverse displacement deposition solution, comprising the following steps:

[0047] (1) Immerse the copper substrate in an alkaline chemical degreasing solution at 45°C and stir for 7 minutes; after fully cleaning the copper substrate treated with alkaline chemical degreasing with water, immerse it in an acidic etching solution at 24°C for 3 minutes; then take it out and Rinse sufficiently with water to obtain a cleaned copper substrate.

[0048] Among them: Alkaline chemical degreasing liquid is prepared by dissolving 20g of sodium hydroxide, 75g of sodium carbonate, and 7.5g of sodium silicate in 1L of pure water.

[0049]The acidic etching solution is prepared by dissolving 35g of sulfuric acid and 76g of sodium persulfate in 1L of pure water.

[0050] ⑵ Preparation of reverse displacement deposition solution:

[0051] Add 20g of nickel nitrate, 25g of nickel acetate, 300g of sodium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com