A kind of preparation method of mud pump cylinder liner

A mud pump and cylinder liner technology, which is applied in the field of mud pump cylinder liner preparation, can solve the problems of high price of ceramic cylinder liners, influence on drilling construction progress, low hardness and toughness, etc., and achieve toughness and other mechanical properties. The effect of lifting and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention relates to a preparation method of a mud pump cylinder liner, comprising the following steps:

[0041] Step 1. Rough machining the inner liner of the cylinder liner;

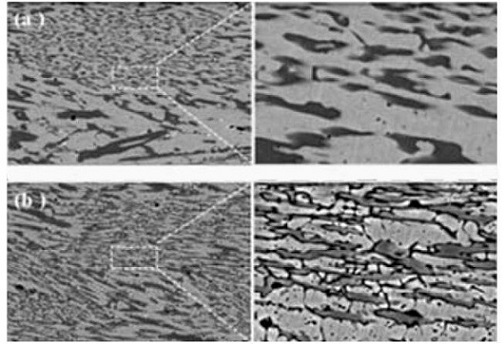

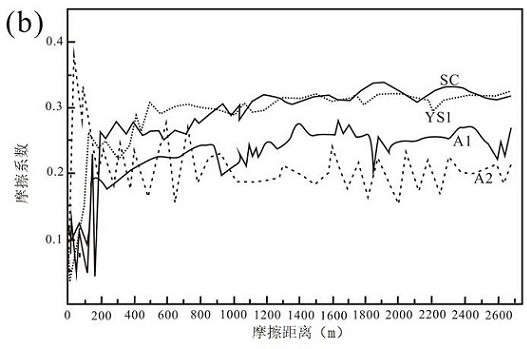

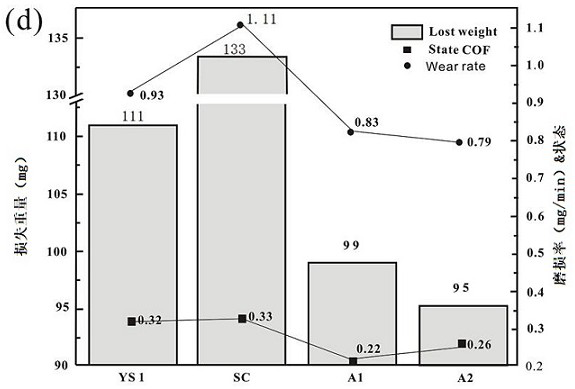

[0042] Step 2. Perform magnetic field heat treatment and tempering on the rough-processed cylinder liner to form a martensitic structure with dislocation cells through deformation and increase the precipitation of carbides (with the help of a magnetic field, improve the structure and precipitate More carbides, improve the hardness and comprehensive wear resistance of the cylinder liner);

[0043] Step 3, processing and grinding the inner liner of the cylinder liner after the magnetic field heat treatment in Step 2;

[0044] Step 4: After heating the outer casing of the cylinder liner to 400-500° C., the mud pump cylinder liner is obtained by inserting and machining the polished inner liner of the cylinder liner.

[0045]Wherein, when the inner liner of the cylinder liner is a metal inner l...

Embodiment 1

[0047] A preparation method of a mud pump cylinder liner, comprising the following steps:

[0048] Step 1. Rough machining of the inner liner of the cylinder liner: The inner liner of the cylinder liner is processed to the appropriate size by a lathe according to the requirements of the drawings.

[0049] Step 2. Magnetic field heat treatment and quenching and tempering treatment of the inner tank of the cylinder liner:

[0050] a. Magnetic field heat treatment and quenching stage: heat the rough-processed cylinder liner to 1050°C, keep the temperature for 120min, and then quench it to room temperature. During the quenching process, an alternating magnetic field with a magnetic field strength of 0.5T is introduced.

[0051] b. Magnetic field heat treatment and tempering stage: heat the liner liner after magnetic field heat treatment and quenching to 550°C, keep the temperature for 180min, then air-cool to room temperature, and introduce an alternating magnetic field with a mag...

Embodiment 2

[0055] A preparation method of a mud pump cylinder liner, comprising the following steps:

[0056] Step 1. Rough machining of the inner liner of the cylinder liner: The inner liner of the cylinder liner is processed to the appropriate size by a lathe according to the requirements of the drawings.

[0057] Step 2. Magnetic field heat treatment and quenching and tempering treatment of the inner tank of the cylinder liner:

[0058] a. Magnetic field heat treatment and quenching stage: heat the rough-processed cylinder liner to 1050℃, keep the temperature for 120min, and then quench it to room temperature. During the quenching process, an alternating magnetic field with a magnetic field strength of 0.1T is introduced.

[0059] b. Magnetic field heat treatment and tempering stage: The liner liner after magnetic field heat treatment and quenching is heated to 550 ° C, kept for 180 minutes, and then air-cooled to room temperature. During the tempering process, an alternating magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com