A kind of aging treatment method of cobalt-based alloy wire

A cobalt-based alloy and aging treatment technology is applied in the field of aging treatment of cobalt-based alloy wires, which can solve the problems of long heat treatment time, excessive heating and holding time, and reduce alloy yield strength. Conducive to defect elimination and atomic segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

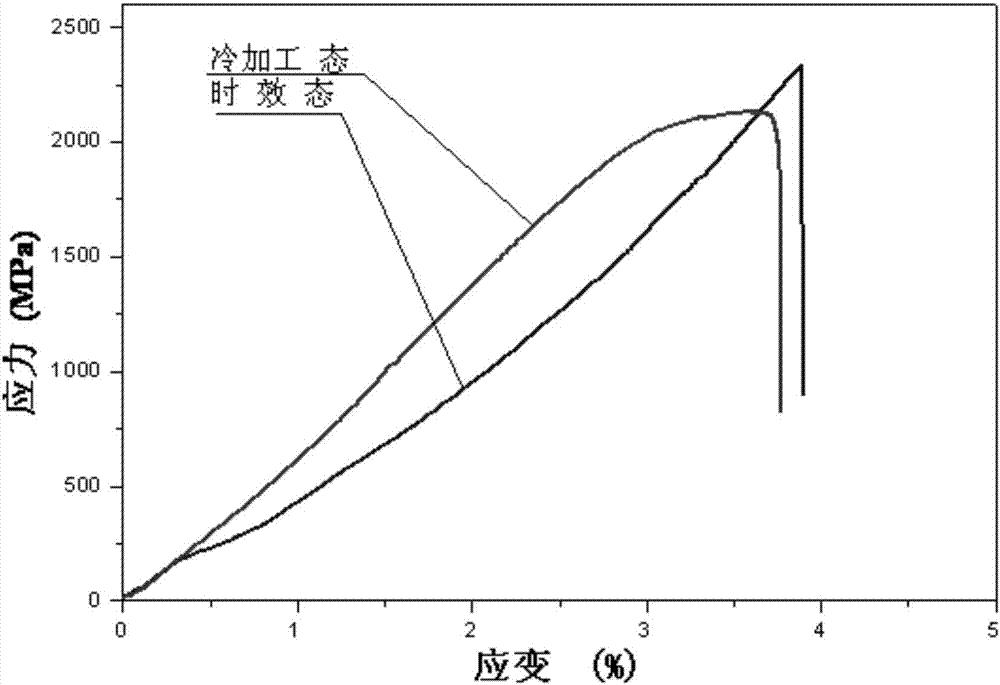

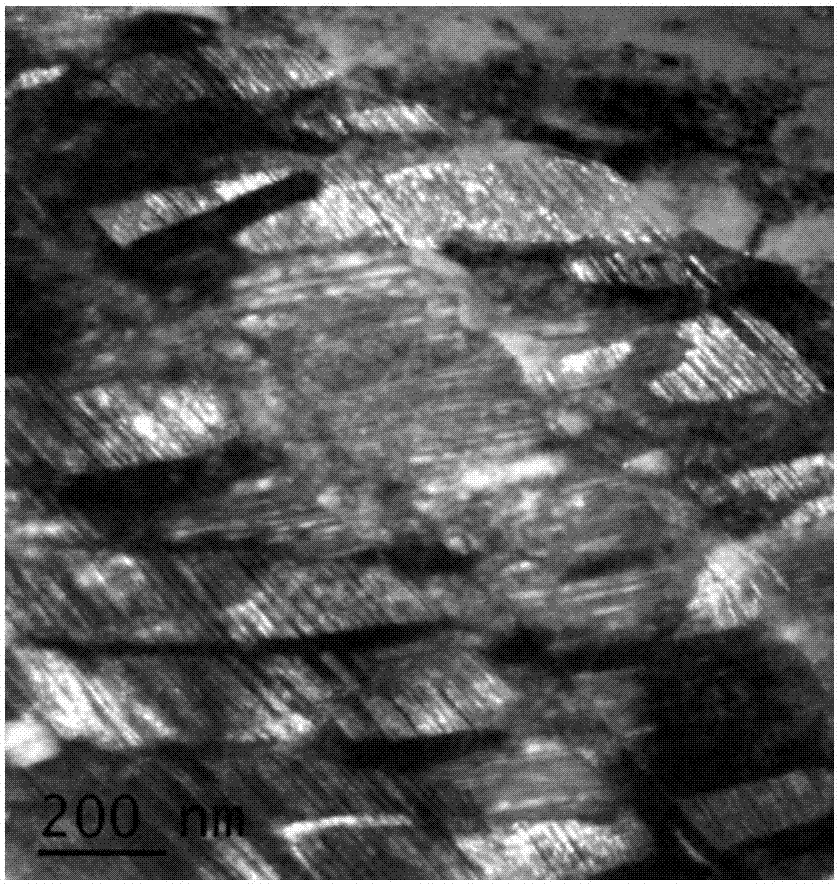

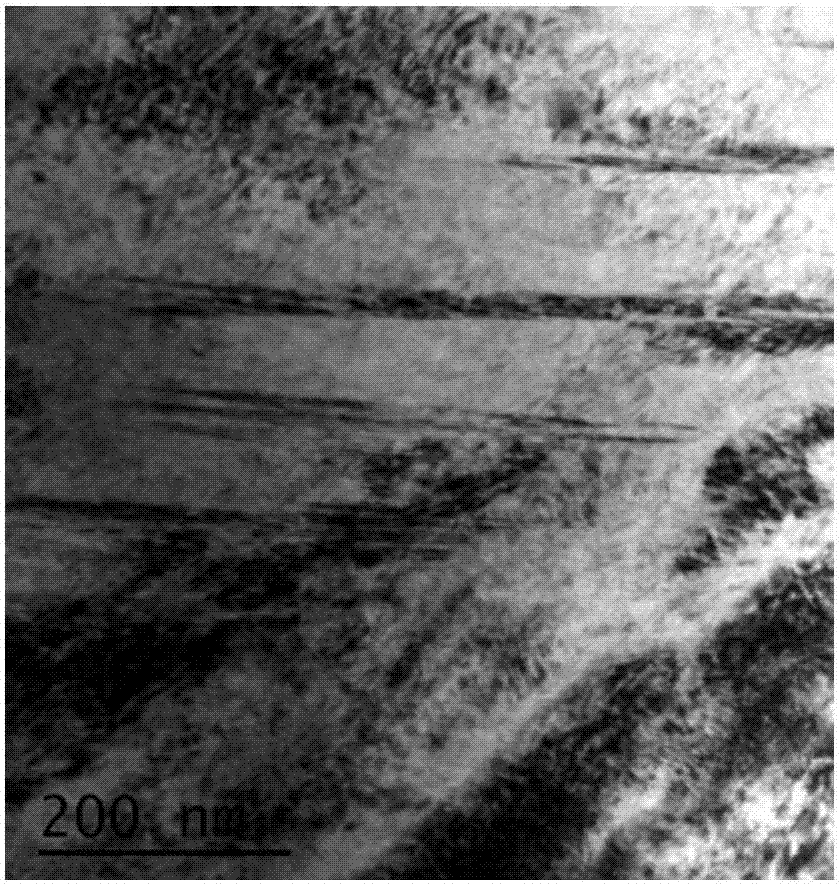

[0033] This embodiment takes MP35N alloy wire as an example to further illustrate the aging treatment method of the present invention. The aging treatment method of this embodiment improves the atomic segregation and defect elimination in the aging treatment process of MP35N alloy wire. It is beneficial to the elimination of defects and the redistribution of elements and avoids coarse grains, thereby improving the strength of MP35N alloy wire and maintaining its toughness, and finally improving the service performance of MP35N alloy.

[0034] The MP35N alloy wire of this embodiment is obtained by cold drawing, and the deformation is controlled at 60%. The material involved in the MP35N alloy wire is a cobalt-based alloy with an element content of 35% Co, 35% Ni, 20% Cr, and 10% Mo. (MP35N) wire.

[0035] The aging treatment method of the MP35N alloy wire of the present embodiment may further comprise the steps:

[0036] Step 1: Place a certain amount of sand (mainly SiO2) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com