Low-odor and high-performance plant fiber reinforced regenerated polypropylene composite material and preparation method thereof

A technology for regenerated polypropylene and plant fibers, applied in low-odor, plant fiber-reinforced recycled polypropylene composite materials and their preparation, high-performance fields, can solve the loss of mechanical properties, unpleasant odor, inconvenient application and promotion of automotive interior parts, etc. problem, to reduce shear damage and improve odor emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

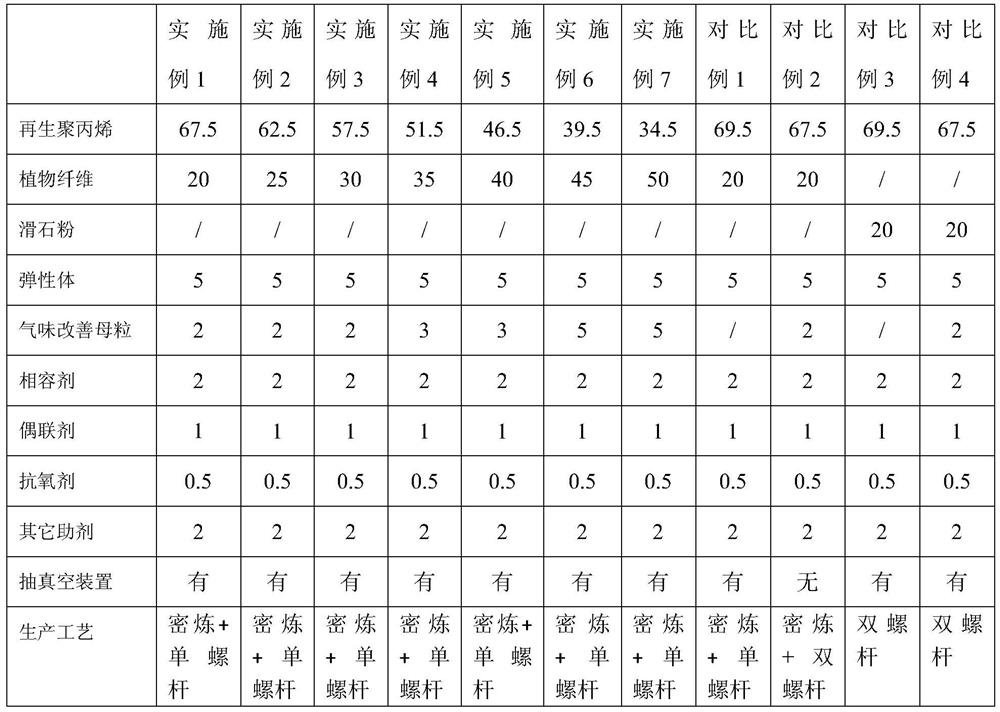

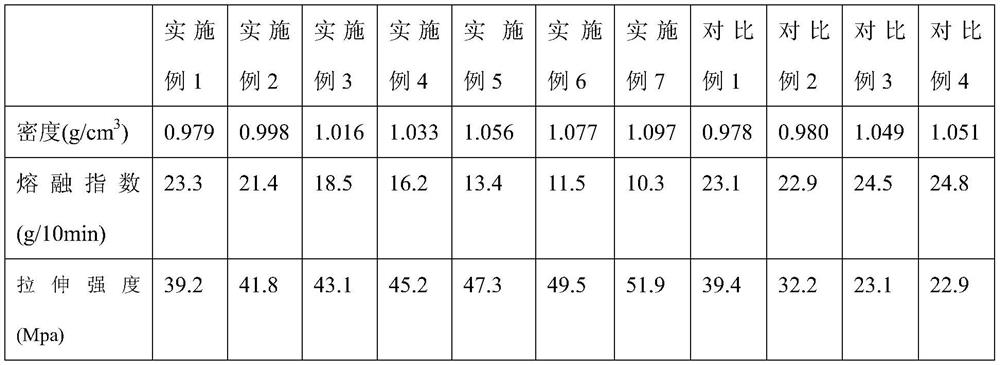

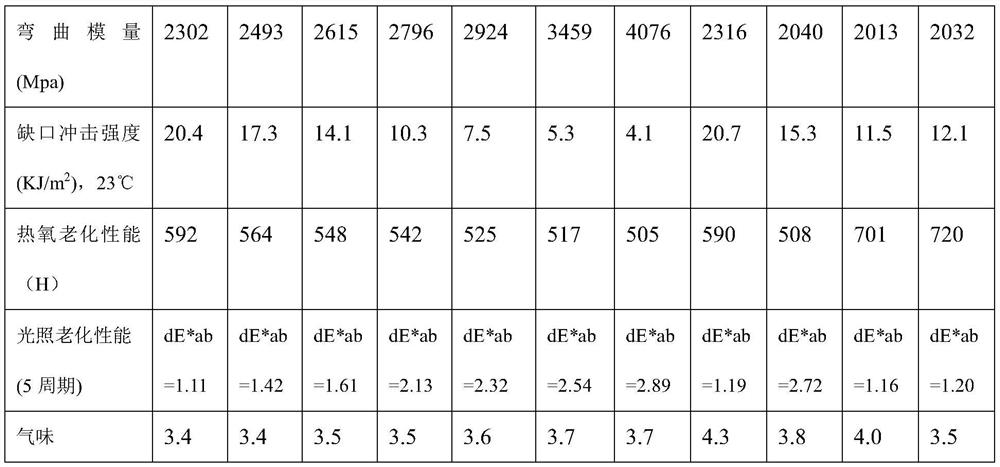

Examples

preparation example Construction

[0043] (1) Preparation of odor-improving masterbatch

[0044] Add low-density polyethylene, porous activated carbon, nano-titanium dioxide, and lubricants into the high-speed mixer for uniform mixing according to the weight components, and then transfer them to the mixing chamber of the internal mixer for high-speed internal mixing. The refined and mixed bulk material is transferred to the double-arm feeding port for feeding, and is extruded by a single-screw extruder, air-cooled, and granulated to prepare the odor-improving masterbatch. Among them, the temperature of the mixing room in the internal mixer is set at 160-180°C, the diameter of the single screw is 60 mm, and the ratio of length to diameter is 10. The single screw extruder is divided into three sections to control the temperature, from the feeding port to the head The temperature of the section is 165°C, 170°C, 180°C in turn

[0045] (2) Modification of plant fibers.

[0046] The plant fibers selected in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com