Epoxy curing agent as well as preparation method and application thereof

An epoxy curing agent and reaction technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of unsuitable curing agent, expensive polythiol, and low crosslinking density, so as to increase the curing speed and improve Low curing agent activity, effect of improving low temperature surface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

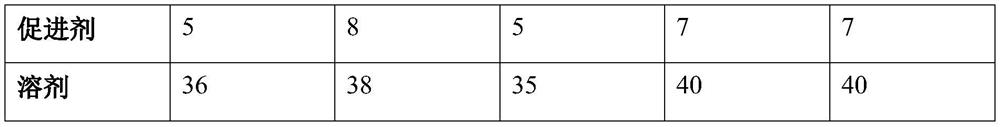

Embodiment 1

[0041] First place 20g of hexamethylenediamine and 8g of thiourea in the reactor, control the reaction temperature at 120°C to 150°C, react for 2h, add 22g of polyetheramine D400, continue the reaction for 1h, add 9g of polypropylene glycol diglycidyl ether to react, control The temperature is 70°C to 90°C, react for 2 hours, add 5g of triethanolamine, 16g of cardanol, and 20g of benzyl alcohol to the reaction kettle in sequence, mix evenly, and discharge to obtain an epoxy curing agent.

Embodiment 2

[0043] First place 19g of isophoronediamine and 7g of thiourea in the reactor, control the reaction temperature at 120°C to 150°C, react for 2h, add 20g of polyetheramine D230, continue the reaction for 1h, add pentaerythyl glycol diglycidol React 8g of ether, control the temperature at 70°C to 90°C, react for 2h, add 8g of triethanolamine, 16g of nonylphenol, and 22g of benzyl alcohol to the reaction kettle in sequence, mix evenly, and discharge to obtain an epoxy curing agent.

Embodiment 3

[0045] Firstly, put 20g of methylcyclopentyldiamine and 7g of thiourea in the reactor, control the reaction temperature at 120℃~150℃, react for 2h, add 30g of polyetheramine T403, continue the reaction for 1h, add polyethylene glycol diglycidol React 8g of ether, control the temperature at 70°C to 90°C, react for 2h, add 5g of 2,4,6-tris(dimethylaminomethyl)phenol, 10g of n-butanol, and 20g of xylene to the reaction kettle in sequence, and mix well , discharging to obtain epoxy curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore d hardness | aaaaa | aaaaa |

| Shore d hardness | aaaaa | aaaaa |

| Shore d hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com