Vulcanized chelated zero-valent iron as well as preparation method and application thereof

A technology of zero-valent iron and chelated state, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of easy aggregation of zero-valent iron and high resistance of iron oxide film, and achieve Good adsorption performance, resistance reduction, and the effect of overcoming defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

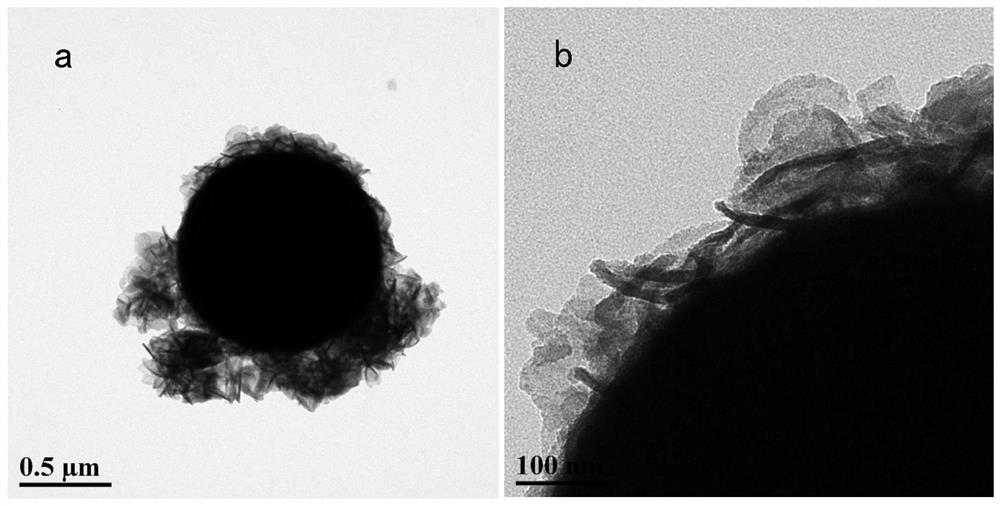

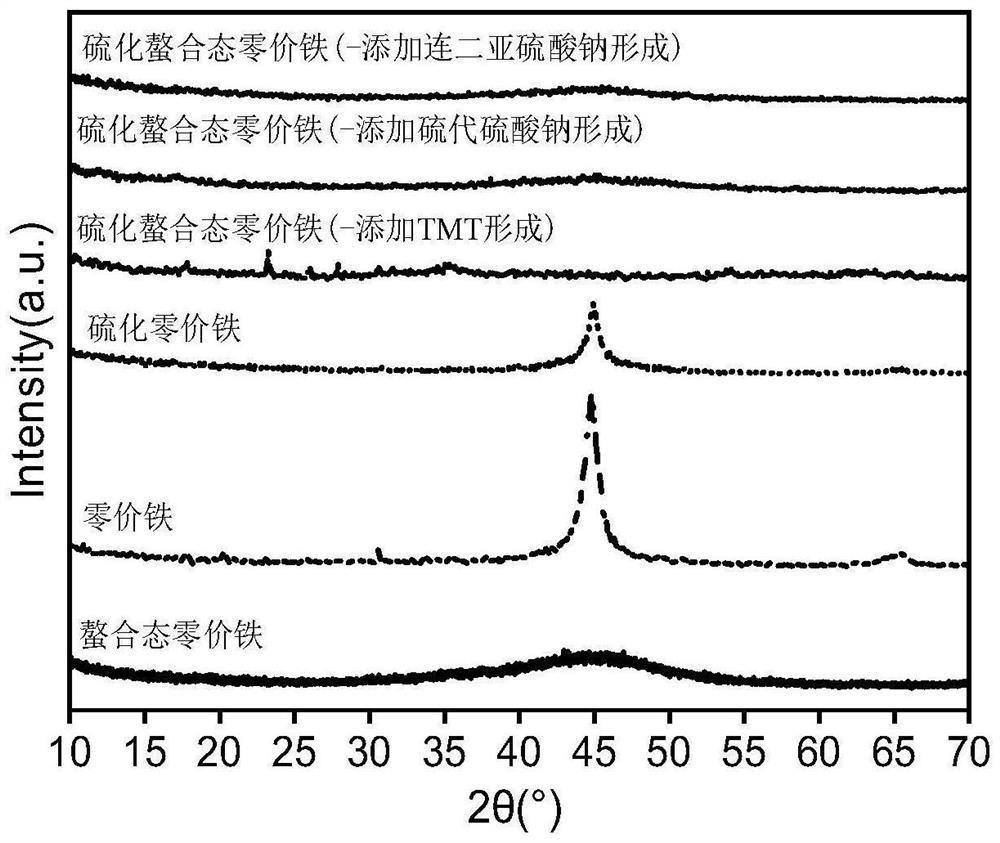

Image

Examples

Embodiment 1

[0040] A preparation method of sulfurized chelated zero-valent iron, comprising the following steps:

[0041] Add 3.5000g of ferrous sulfate and 4mL of N,N-dimethylformamide into a three-necked flask filled with 200mL of ultrapure water at normal temperature and pressure, and stir for 5 minutes to obtain a mixed solution; In a 100mL beaker, add 4.0000g sodium borohydride, 75mL ultrapure water, stir and dissolve to obtain NaBH 4 solution; at normal temperature and pressure, the NaBH 4 The solution was added dropwise to the mixed solution, the solution turned black and gradually formed particles, NaBH 4 After the dropwise addition of the solution was completed, 3.5000 g of triazine trithiol trisodium salt hydrate (TMT) was added, stirred and reacted for 15 minutes, separated and washed, and freeze-dried at -60° C. under vacuum to obtain sulfide-chelated zero-valent iron.

Embodiment 2

[0043] A preparation method of sulfurized chelated zero-valent iron, comprising the following steps:

[0044] Add 4.0000g of ferrous sulfate and 5mL of N,N-dimethylformamide into a three-necked flask filled with 250mL of ultrapure water at normal temperature and pressure, and stir for 10 minutes to obtain a mixed solution; In a 100mL beaker, add 4.7000g sodium borohydride, 90mL ultrapure water, stir and dissolve to obtain NaBH 4 solution; at normal temperature and pressure, the NaBH 4 The solution was added dropwise to the mixed solution, the solution turned black and gradually formed particles, NaBH 4 After the dropwise addition of the solution was completed, 3.7000 g of sodium thiosulfate was added, stirred and reacted for 17 minutes, separated and washed, and freeze-dried at -55° C. under vacuum to obtain zero-valent iron in a sulfide chelated state.

Embodiment 3

[0046] A preparation method of sulfurized chelated zero-valent iron, comprising the following steps:

[0047] Add 5.2000g of ferrous sulfate and 6mL of N,N-dimethylformamide into a three-necked flask filled with 300mL of ultrapure water at normal temperature and pressure, and stir for 15 minutes to obtain a mixed solution; In a 100mL beaker, add 5.0000g sodium borohydride, 100mL ultrapure water, stir and dissolve to obtain NaBH 4 solution; at normal temperature and pressure, the NaBH 4 The solution was added dropwise to the mixed solution, the solution turned black and gradually formed particles, NaBH 4 After the solution was added dropwise, 4.0000 g of sodium dithionite was added, stirred and reacted for 20 minutes, separated and washed, and freeze-dried at -50° C. under vacuum to obtain sulfide-chelated zero-valent iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com