Adsorbent for separating ethylbenzene from C8 aromatic hydrocarbon and preparation method thereof

A technology of carbon octane aromatics and adsorbent, which is applied in the field of adsorbent and its preparation for the separation of ethylbenzene from mixed carbon octane aromatics, which can solve the problems of reduced separation capacity and separation performance of adsorbents, and achieve reduced operating severity and improved The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

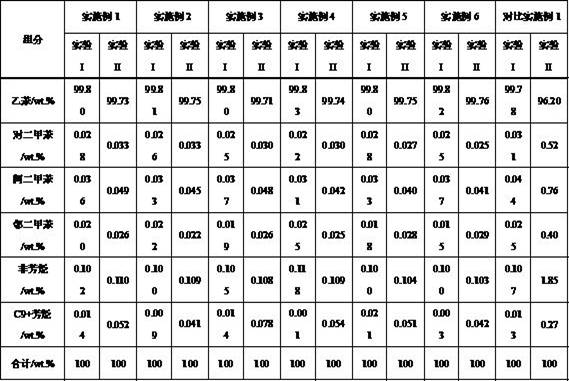

Examples

Embodiment 1

[0035] (1) Fully mix 5 kg X zeolite with 0.48 kg kaolin to form a mixed powder. Put the powder into the turntable of the sugar coating machine and spray an appropriate amount of water while rolling to make the powder roll into a ball. The total amount of water added in the whole ball rolling process is about 30wt% of the total mass of the powder. The pellets with a particle size of 20-50 mesh were sieved and dried at 140°C for 10 hours.

[0036] (2) Dissolve 3.4 kg of cesium chloride in 40 L of deionized water to prepare a solution for ion exchange of X zeolite pellets.

[0037] (3) Put 4 kg of the dried pellets described in (1) into an exchange kettle, add them into the CsCl solution prepared in (2), and perform ion exchange at 95 °C for 4 h. After the exchange, rinse the exchanged pellets with copious amounts of deionized water. Then, the rinsed pellets were dried at 200°C for 10 hours.

[0038] (4) Dissolve 1.49 kg tetraethyl orthosilicate in 15 kg cyclohexane solution ...

Embodiment 2

[0043] The total amount of water added in the ball rolling process in step (1) is about 40wt% of the total mass of the powder, and other conditions are consistent with Example 1;

[0044] The alkali metal salt adopted in the step (2) is rubidium chloride, and the addition is 2.42 kg, and other conditions are consistent with embodiment 1;

[0045] Step (3) is consistent with embodiment 1;

[0046] Step (4) The organosilicon ester is vinyltrichlorosilane, the dosage is 3.86kg, and the other conditions are the same as in Example 1;

[0047] The roasting atmosphere of step (5) is a helium atmosphere, and other conditions are consistent with embodiment 1;

[0048] Step (6) is consistent with embodiment 1;

[0049] Step (7) is consistent with Example 1.

Embodiment 3

[0051] The total amount of water added in the ball rolling process in step (1) is about 50wt% of the total mass of the powder, and other conditions are consistent with Example 1;

[0052] The alkali metal salt adopted in the step (2) is potassium chloride, and the addition amount is 1.5 kg, and other conditions are consistent with embodiment 1;

[0053] Step (3) is consistent with embodiment 1;

[0054] The organosilicon ester used in step (4) is methylvinyldichlorosilane, the dosage is 5.04kg, and other conditions are consistent with Example 1;

[0055] The roasting atmosphere of step (5) is an argon atmosphere, and other conditions are consistent with embodiment 1;

[0056] Step (6) is consistent with embodiment 1;

[0057] Step (7) is consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com