Method and apparatus for high-efficient crude oil desalination / dehydration

A crude oil dehydration and desalination technology, which is applied in the field of petrochemical industry, can solve the problems of electric field collapse, transformer tripping, desalination/dehydration effect deterioration, etc., and achieve the elimination of stabilization effect, reduction of crude oil water content, desalination/dehydration rate and stable operation improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

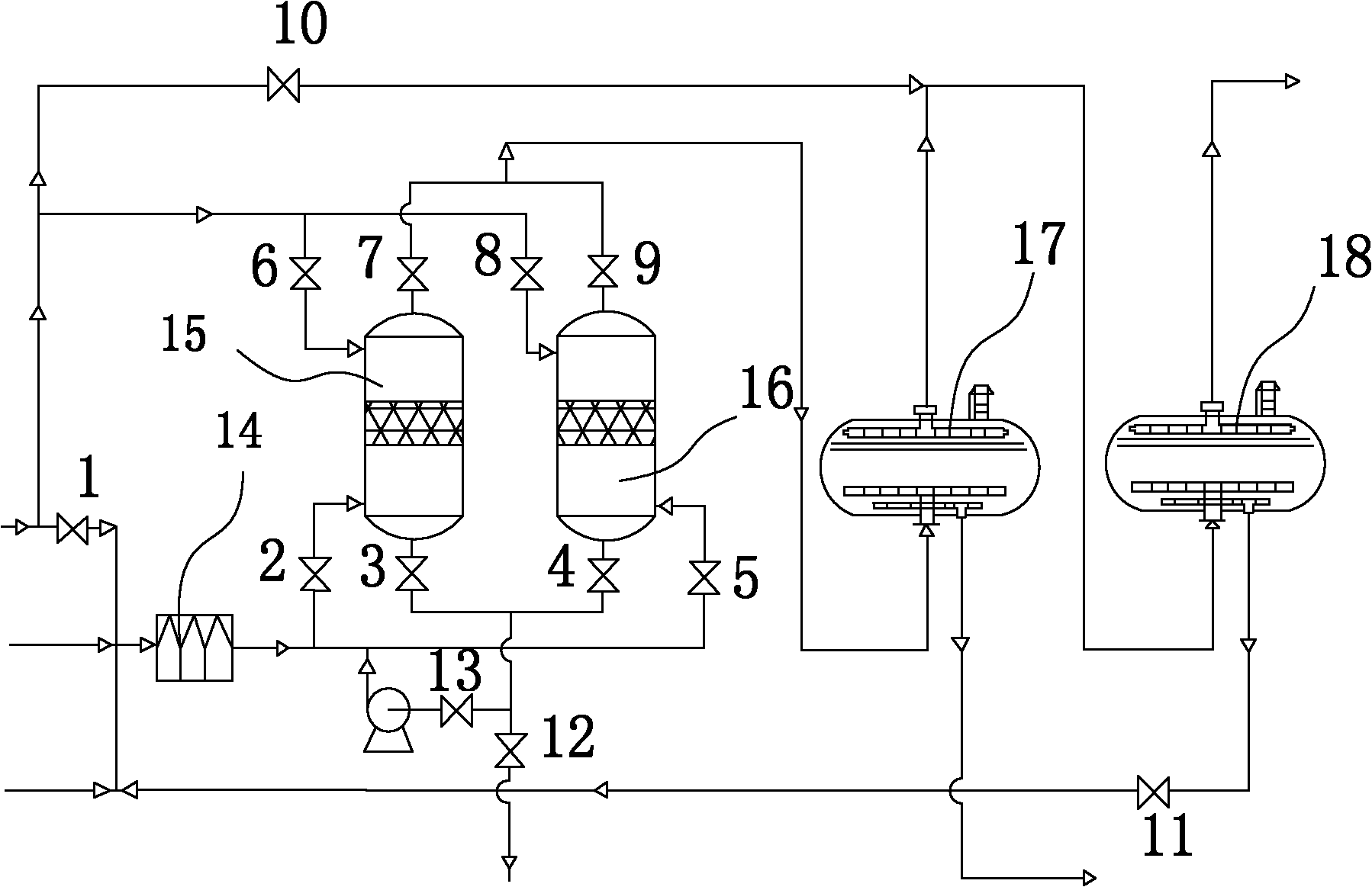

Embodiment 1

[0032] Crude oil density is 846.6Kg / m 3 , with a salt content of 17.0 mgNaCl / l. The combination of filtration method and first-stage electric desalination is adopted. The filter medium layer is polyester fiber with oxidized surface layer, the thickness is 0.25m, and the initial pressure drop is 0.02MPa; the demulsifier model is EC2425A, and the dosage is 5μg / g; The washing water mixed with crude oil and demulsifier is salt-free industrial purified water, PH=7.9, and the dosage is 4% of the crude oil; the electric field form of the electric desalting tank is an alternating electric field, and the electric field strength in the strong field area is 850 V / cm, the electric field strength in the weak field region is 400 V / cm; the temperature of the oil-water emulsion is 110°C. The salt content of a stripped crude oil is 1.3 mgNaCl / L, and the water content is 0.05%.

Embodiment 2

[0034] Crude oil density is 883.2Kg / m 3 , with a salt content of 87.4 mgNaCl / L. The combination of filtration method and two-stage electric desalination is adopted. The filter medium layer is glass fiber paper with a thickness of 0.10m and an initial pressure drop of 0.04MPa; the demulsifier model is FC9303, and the dosage is 10μg / g; the washing water is salt-free industrial purified water, PH=6.7, the secondary water injection volume is 7% of the crude oil, and the secondary saline sewage is mixed with the crude oil and demulsifier before returning to the static mixer; the electric field form of the electric desalination tank is an AC-DC electric field, The electric field intensity of the first-stage electric desalination tank is 900V / cm, and that of the second-stage electric desalination tank is 1000V / cm; the temperature of the oil-water emulsion is 125°C. The salt content of the dide crude oil is 2.6 mgNaCl / L, and the water content is 0.18%.

Embodiment 3

[0036] Crude oil density is 933.6Kg / m 3 , with a salt content of 128.4 mgNaCl / L. The combination of filtration method and two-stage electric desalination is adopted. The filter medium layer is polyester fiber with oxidized surface layer, the thickness is 0.50m, and the initial pressure drop is 0.046MPa; the demulsifier model is EC2425A, and the dosage is 10μg / g; The desalination of this crude oil is quite difficult, and the secondary salty sewage is no longer reused. When mixing with this crude oil and demulsifier, industrial purified water without salt is directly used, its pH=8.5, and the dosage is 13% of the crude oil; The quality of the water used for mixing the primary water injection with crude oil and demulsifier is the same, and the dosage is 8% of the crude oil; the electric field form of the electric desalting tank is a pulse electric field, and the pulse electric field strength of the primary electric desalting tank is 2500V / cm, and the pulse frequency is 1000Hz , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com