Delayed coking and reduced pressure distillation combined processing method

A technology of delayed coking and vacuum residue, which is applied in the fields of vacuum distillation, multi-stage series-connected refining and cracking process treatment, etc., which can solve the problem that the processing device is difficult to process, affects the total liquid yield of coking, and has poor separation accuracy of wax oil. and other problems, to achieve the effect of increasing the processing capacity, reducing the severity of the operation, and reducing the operating cost.

Active Publication Date: 2012-08-29

CHINA PETROLEUM & CHEM CORP +1

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the limitation of the coking fractionation tower process, this technology still cannot achieve satisfactory results in the end

[0003] The coking fractionation tower mainly relies on the heat generated by coking to generate oil and gas to complete the separation of products under normal pressure conditions. Therefore, the separation accuracy of wax oil with a higher boiling point is poor, so that the temperature difference between the 90% point of coking wax oil and the dry point is very large. If If the output of coking wax oil is increased, its quality will become worse, and downstream processing devices will be difficult to process, which will seriously affect the total liquid yield of coking and cause a waste of resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

[0032] All experiments in the examples use the same raw material oil, aiming to compare the effect of improving the yield of coker wax oil under different operating conditions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

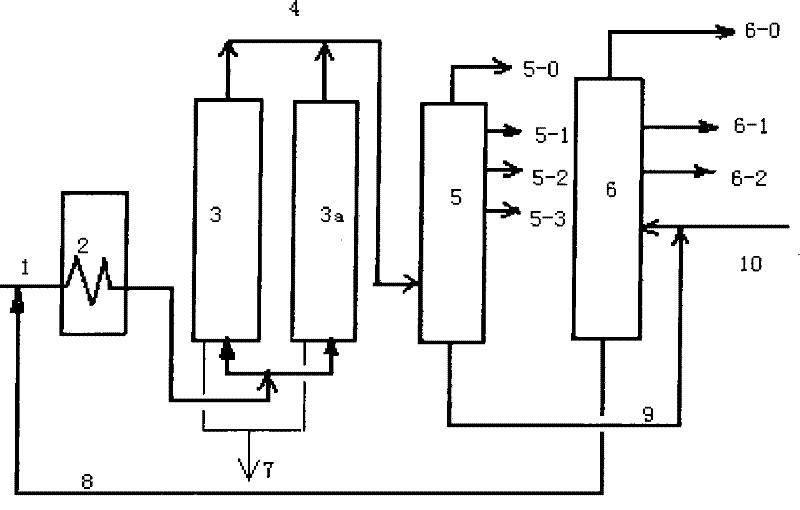

The invention discloses a delayed coking and reduced pressure distillation combined processing method. The method comprises the following steps that: high-temperature gases produced by the delayed coking device are delivered into a coking fractional distillation column for distillation and a dry point of the wax oil is controlled to ensure the quality of the wax oil; and coking tail oil and normal-pressure residual oil are delivered into a reduced pressure distillation device together to further and deep extract residual coking wax, the residual coking wax and straight run wax oil are discharged out from the device at the same time, and reduced pressure residual oil containing a small amount of coke powder is used as delayed coking feed. The method improves the yield of coking wax oil andensures the quality of the coking wax oil. With the increase of the extraction amount of the coking waxy oil, the amount of coking circulation oil is greatly reduced and the processing capacity of the coking device is improved, so the economic benefits are increased.

Description

technical field [0001] The invention belongs to the combined process of thermal processing technology and distillation device, in particular, it is a method for maximum production of distillate oil in the process of delayed coking and vacuum distillation. Background technique [0002] According to statistics, by 2005, the processing capacity of delayed coking units in the world will reach 226.48Mt / a. It can be seen that the coking process is still one of the important means to deal with residual oil. In terms of how to improve the yield of delayed coking liquid, major companies in the world have researched and developed many technical methods, such as: US5925236, US4784744, US5006223, US7067053, CN1448466A, CN1552799A, CN1487056A, CN1246514A, CN1465658A mainly reveal the improvement of delayed coking process , which increases the liquid yield. However, due to the poor separation precision of the coking fractionation tower, the output of the wax oil cannot be guaranteed whil...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10G55/04C10G7/06

Inventor 关明华张学萍

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com