Liquid ammonia phase change cooling type hybrid power thermal management system

A heat management system, phase change cooling technology, applied in the direction of charging system, engine components, combustion engine, etc., can solve the problems of low volume efficiency of ammonia fuel engine, low thermal efficiency, low energy utilization rate, poor combustion effect, etc., to increase the system Reliability, precise injection timing, and the effect of preventing cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in more detail below in conjunction with accompanying drawing example:

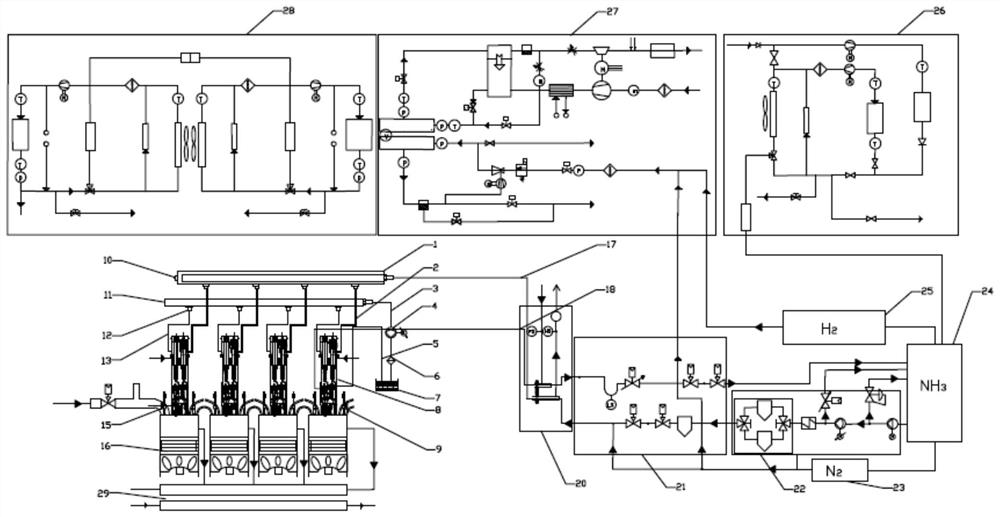

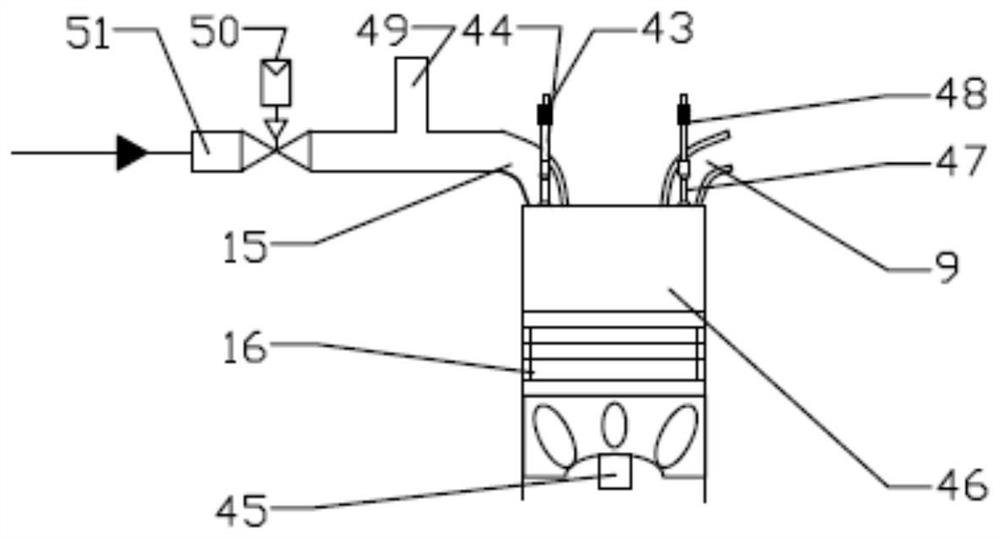

[0049] combine Figure 1-17 , figure 1 It is a schematic diagram of the overall structure of the present invention, a liquid ammonia phase-change cooling hybrid thermal management system, including: a fuel supply system, a liquid ammonia and hydrogen supply system, a liquid ammonia-diesel dual-fuel cylinder 16, and a liquid ammonia-diesel dual-fuel injector 8 , a hydrogen fuel cell supply system 27 , a cooling system 28 , a double-action heat pump 26 and a waste heat utilization system 29 . The fuel supply system consists of a fuel tank 7, a filter 6, a high-pressure fuel pump and a motor 4, a fuel common rail pipe 11, a flow limiter 12, high-pressure fuel pipes 3 and 13, and an injector 8. , The filter 6 communicates with the oil tank 7, and the flow limiter 12 communicates with the injector 14 through the high pressure oil pipe 13.

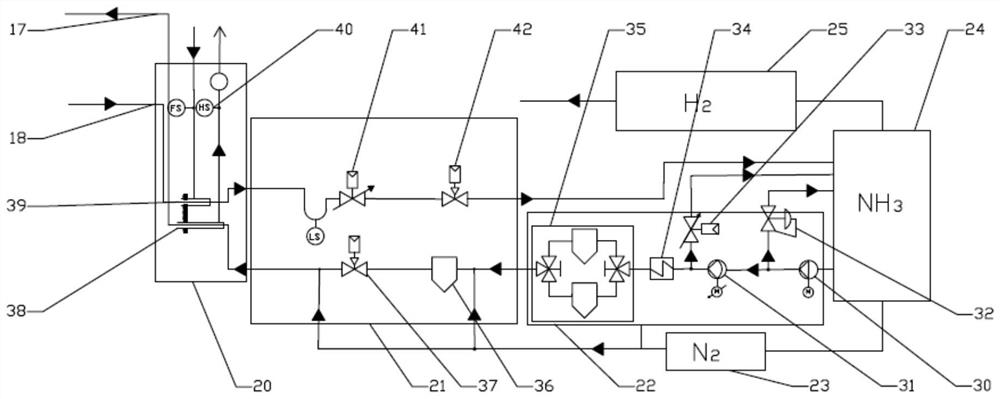

[0050] figure 2 It is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com