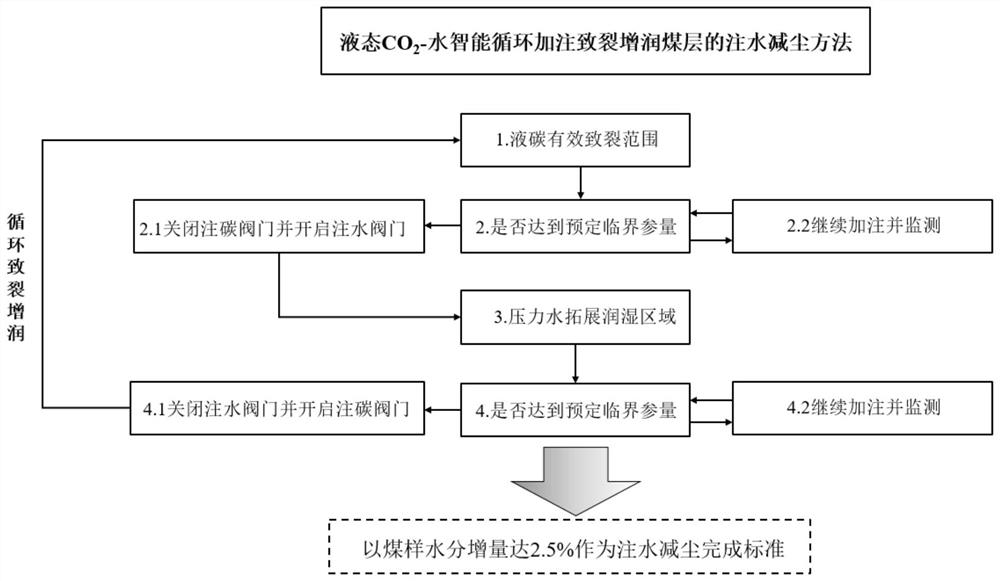

Water injection dust reduction method for cracking and moistening coal seam through intelligent circulating filling of liquid carbon and water

A coal seam and fracturing technology, which is applied in the field of coal seam fracturing, moisturizing, intelligent cycle filling and dust reduction, can solve the problems of unsatisfactory water injection dust reduction effect, high manual labor intensity, long water injection cycle, etc., to achieve improved efficiency and intelligence Level, wide monitoring range, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

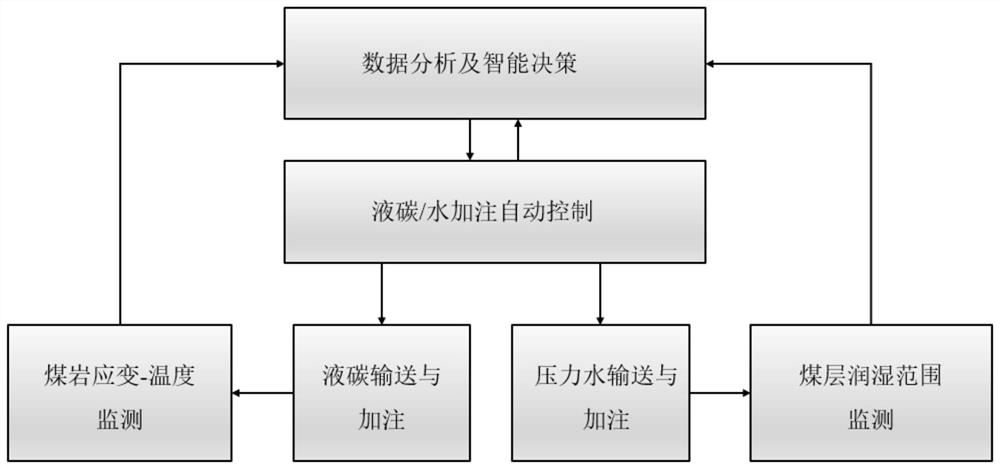

Method used

Image

Examples

Embodiment Construction

[0023] First, the advancement surface 60m uses the ZDY120S type coal mine along the coal seam tilt, the hydraulic drilling machine construction, the number 1 # ~ 6 #, the opening position is 2.5m from the top bottom plate, drilling diameter φ 1 = 80mm, drilling pitch is 25m, the drilling length is determined to be 120m according to the length of the working surface length, the water seam water permeability, and the direction of drilling direction. When the main bore is reached to the design depth, the main drilling is round, using the KHYD-140 type horizontal directional drilling rig 360 ° uniformly arranged 6 branch drilled holes, and the branch drilling axial direction is 15 m;

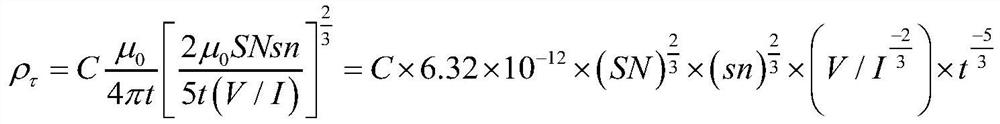

[0024]Next, computer intelligent decision and analysis device installed with a modular special package is connected to the AFPX-AD2 type PLC controller, computer intelligent decision and analysis device can achieve monitoring data correction, conversion and positive inversion analysis. Calculation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com