Steelmaking method for smelting high-carbon low-phosphorus steel through converter

A converter smelting, low-phosphorus steel technology, applied in the field of metallurgical production, can solve the problems of easy splashing end-point carbon pulling rate, unstable steelmaking and other problems, and achieve the effects of reducing lime consumption, stable smelting and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Equipment parameters and material components

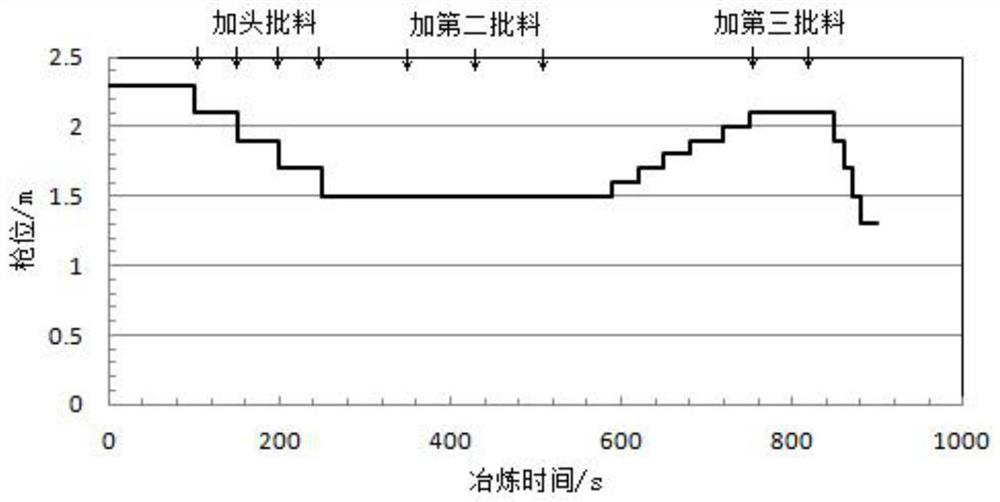

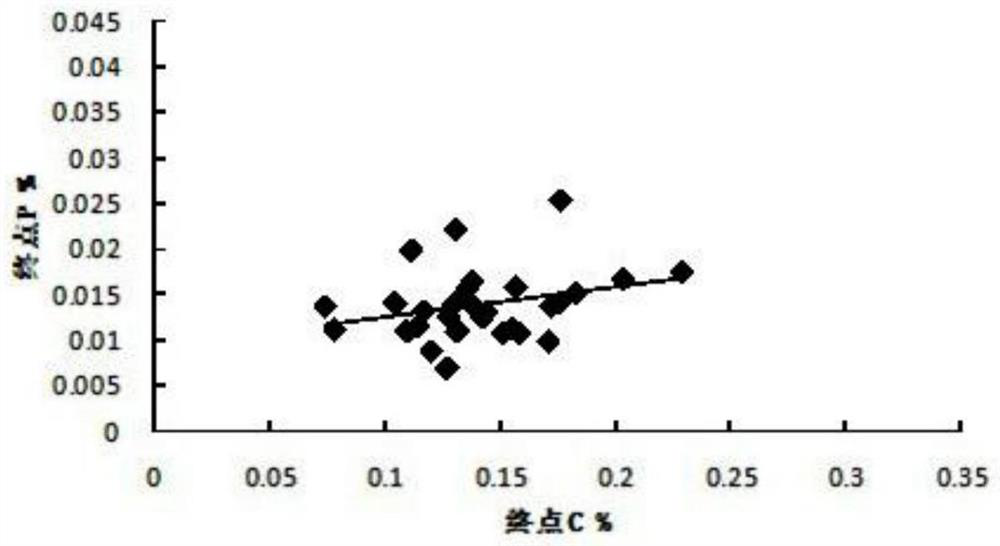

[0031] 120T reincarnation converter is a tube type, the furnace is 0.96m 3 / t. The oxygen gun is 5 welllavar tube type, and the oxygen pressure is 0.60mPa, the standard flow is 400 nm. 3 / min. The bottom blow mode has three, nitrogen patterns, nitrogen-argon switch mode, full argon mode, heavy rail steel to all argon mode, and flow rate of 80 nm. 3 / h. A set of vice gun systems, each of the stoves, and the o-like two steel samples. Packing: High quality scrap (waste blank, scrap) 25T, iron water 125t. The iron water temperature is 1320 ~ 1400 ° C, and the component is shown in Table 1. This type of load system is rich in heat, and iron oxide can be added 3000 to 5000 kg. As shown in Table 2, the main material composition is shown in Table 3.

[0032] Table 1 Iron Water Condition%

[0033]

[0034] Table 2 main materials%

[0035]

[0036] Table 3U75V-T rail steel ingredient requirements%

[0037]

[0038] First, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com