High-strength insulating cpvc material and preparation method thereof

A high-strength, raw material technology, applied in the field of CPVC, can solve the problems of poor impact resistance, enhanced CPVC resin molecular chain force, and decreased thermal stability, and achieve the effect of improving thermal conductivity and huge application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

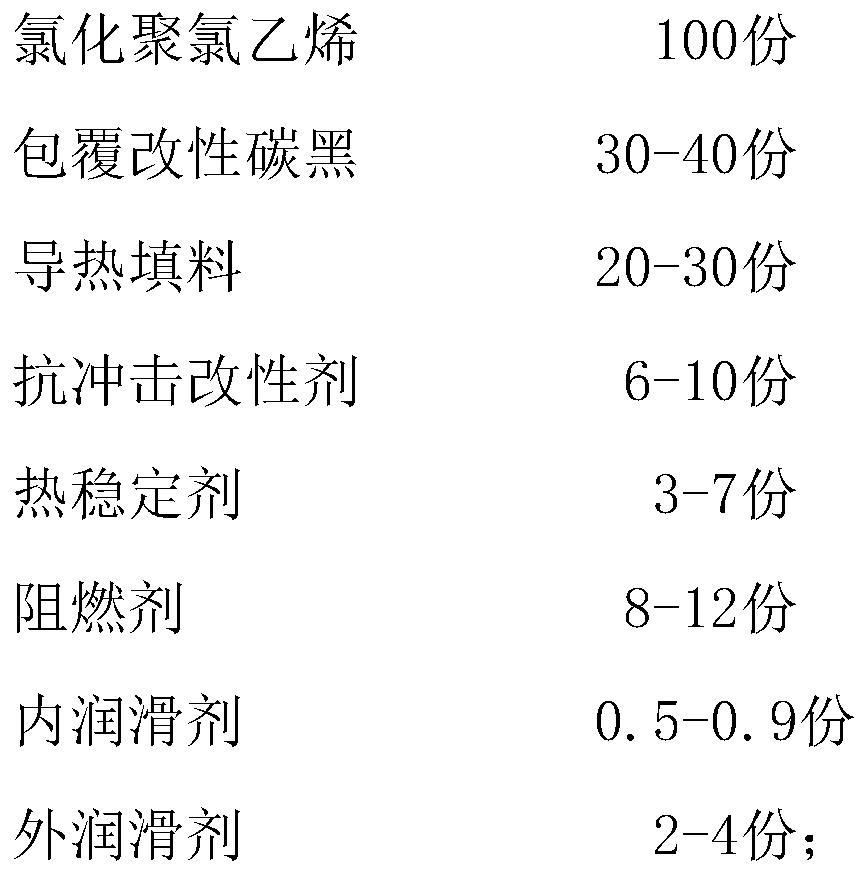

[0027] A high-strength insulating cpvc material, comprising the following raw materials in parts by weight:

[0028]

[0029] Wherein, the preparation method of described coated modified carbon black comprises the steps:

[0030] (1) Add 15 parts by weight of polyvinyl chloride and 7.5 parts by weight of plasticizer to 100 parts by weight of organic solvent, heat up to 55°C for stirring and dissolving, then add 30 parts by weight of carbon black, and stir evenly to obtain a suspension Liquid, the suspension is added dropwise to deionized water for precipitation, after filtration, washing and drying, a single-layer coated carbon black is obtained;

[0031] (2) Add 45 parts by weight of single-layer coated carbon black in 100 parts by weight of deionized water, continue to add 11 parts by weight of butyl acrylate, 7 parts by weight of methyl methacrylate, 4.5 parts by weight of Acrylic acid and 0.4 parts by weight of thermal initiator, after the addition is completed, the te...

Embodiment 2

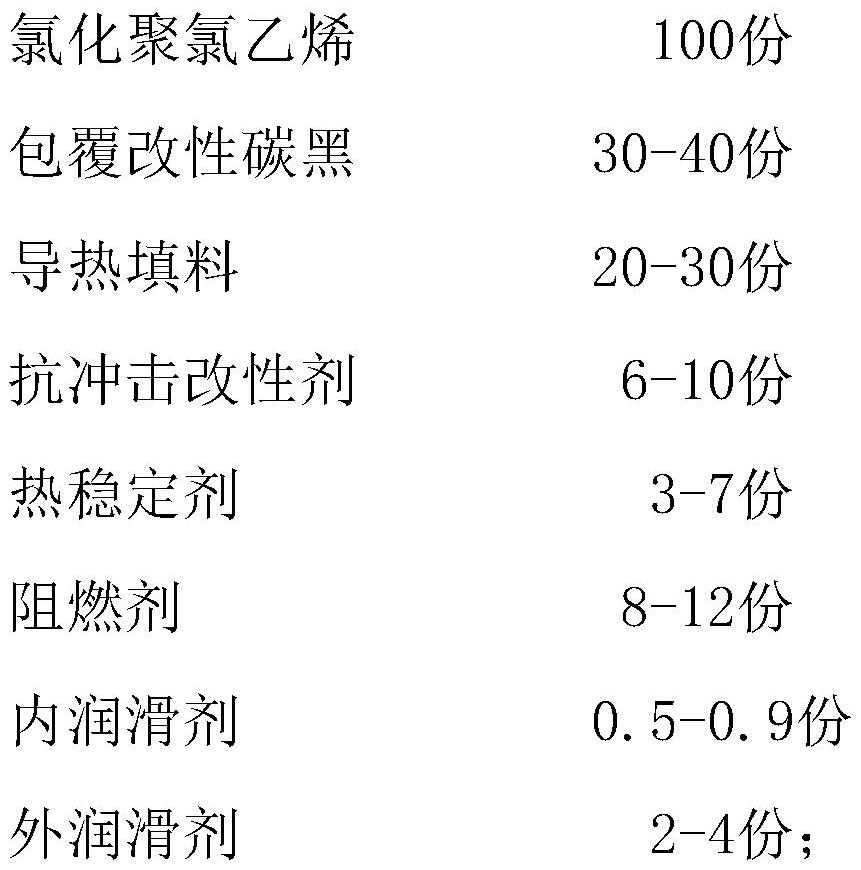

[0044] A high-strength insulating cpvc material, comprising the following raw materials in parts by weight:

[0045]

[0046] Wherein, the preparation method of described coated modified carbon black comprises the steps:

[0047] (1) Add 10 parts by weight of polyvinyl chloride and 5 parts by weight of plasticizer to 100 parts by weight of organic solvent, heat up to 50°C for stirring and dissolving, then add 25 parts by weight of carbon black, and stir evenly to obtain a suspension Liquid, the suspension is added dropwise to deionized water for precipitation, after filtration, washing and drying, a single-layer coated carbon black is obtained;

[0048] (2) Add 40 parts by weight of single-layer coated carbon black in 100 parts by weight of deionized water, continue to add 10 parts by weight of butyl acrylate, 6 parts by weight of methyl methacrylate, 4 parts by weight of Acrylic acid and 0.3 parts by weight of thermal initiator, after the addition is completed, the temper...

Embodiment 3

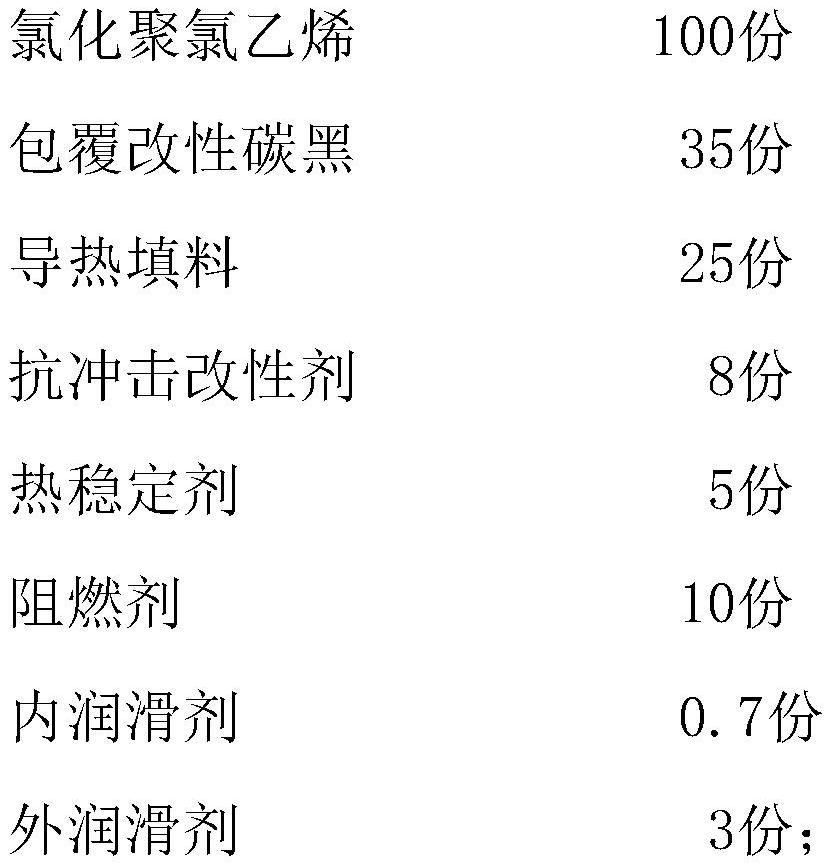

[0061] A high-strength insulating cpvc material, comprising the following raw materials in parts by weight:

[0062]

[0063] Wherein, the preparation method of described coated modified carbon black comprises the steps:

[0064] (1) Add 20 parts by weight of polyvinyl chloride and 10 parts by weight of plasticizer to 100 parts by weight of organic solvent, heat up to 60°C to stir and dissolve, then add 35 parts by weight of carbon black, and stir evenly to obtain a suspension Liquid, the suspension is added dropwise to deionized water for precipitation, after filtration, washing and drying, a single-layer coated carbon black is obtained;

[0065] (2) Add 50 parts by weight of single-layer coated carbon black in 100 parts by weight of deionized water, continue to add 12 parts by weight of butyl acrylate, 8 parts by weight of methyl methacrylate, 5 parts by weight of Acrylic acid and 0.5 parts by weight of thermal initiator, after the addition is completed, the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com