A kind of preparation method of sapphire whisker and ZRO2 synergistically toughened Al2O3 ceramics

A technology of zro2-ce2o3 and sapphire, which is applied in the field of preparation of sapphire whiskers and ZrO2 synergistically toughened Al2O3 ceramics, can solve the problems of harsh synthesis process, difficulty in preparing high-performance ceramic materials, and difficult control of toughening effect, etc. The effect of uneven distribution and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

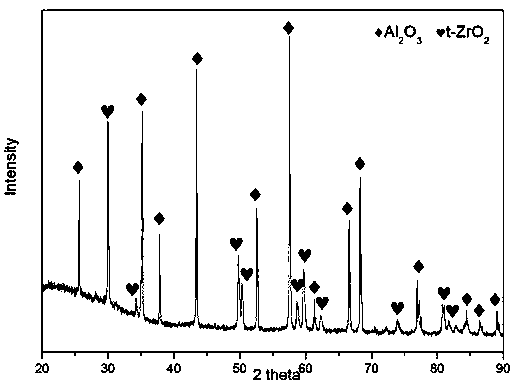

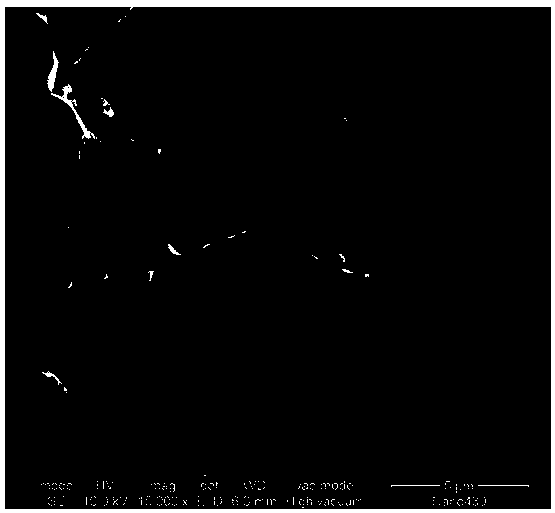

[0025] Al 2 o 3w with ZrO 2 synergistically toughened Al 2 o 3 Ceramic materials, the specific method is as follows:

[0026] (1) with Al 2 o 3 powder as matrix raw material, with Al 2 o 3w For the toughening and reinforcing phase, ZrO 2 Powder is the toughening phase, where Al 2 o 3 Powder particle size 2 o 3w The aspect ratio of > 3:1, the length > 5μm, ZrO 2 The particle size of the powder is less than 1μm, as CeO 2 As a stabilizer, CeO 2 The purity is 99.9%, the Al 2 o 3w Stir mechanically for 15 minutes, then press Al 2 o 3 : ZrO 2 -CeO 2 :Al 2 o 3w The volume fraction ratio is 75%: 15%: 10% for batching, where ZrO 2 -CeO 2 ZrO in 2 : CeO 2 The molar mass fraction ratio is 88%: 12%, with absolute ethanol as solvent, with ZrO 2 The ball is used as a ball milling medium, mixed on a roller ball mill for 24 hours, and the resulting suspension is ultrasonically treated for 15 minutes, dried and granulated to obtain Al 2 o 3 -ZrO 2 -CeO 2 -Al 2 o ...

Embodiment 2

[0030] Press Al 2 o 3 The volume fraction of powder is 60%, ZrO 2 -Y 2 o 3 The volume fraction is 20%, Al 2 o 3w The volume fraction is 20% for batching, where ZrO 2 : Y 2 o 3 The molar mass fraction ratio is 97%: 3%, and Al is prepared according to the method in Example 1 2 o 3 For ceramics, heat up to 1400°C and hold for 2 hours, and the sintering atmosphere is air during the whole process. The Al prepared in this example 2 o 3 The relative density of the ceramic is 99.1%, the hardness is 13Gpa, the bending strength is 1000MPa, and the fracture toughness is 6.5MPa m 1 / 2 .

Embodiment 3

[0032] Press Al 2 o 3 The volume fraction of powder is 80%, ZrO 2 -Yb 2 o 3 The volume fraction is 10%, Al 2 o 3w The volume fraction is 10% for batching, where ZrO 2 : Yb 2 o 3 The molar mass fraction ratio is 92%: 8%, and Al is prepared according to the method in Example 1 2 o 3 For ceramics, heat up to 1500°C and hold for 2 hours, and the sintering atmosphere is air during the whole process. The Al prepared in this example 2 o 3 The relative density of the ceramic is 99.5%, the hardness is 12Gpa, the bending strength is 950MPa, and the fracture toughness is 6MPa m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com