A kind of alumina ceramic sintered body and its preparation method and application

A technology of alumina ceramics and sintered bodies, applied in the field of alumina ceramics, can solve the problems of difficult to effectively control columnar crystals, limited improvement of alumina ceramics, influence on the properties of alumina ceramics, etc., to achieve excellent mechanical properties, easy and controllable production , the effect of high fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of embodiment 1~8 and comparative example 1~4 is:

[0066] 1) Weigh the raw materials according to the proportion, fully mix the cerium oxide and niobium oxide, and then mix them with high-purity Al 2 o 3 Powder mixing, adding alcohol and corundum balls for wet grinding and mixing, the volume ratio of powder, corundum balls and solvent is 2:4:7, the ball mill adopts planetary ball mill, the diameter of corundum balls is at least one of Φ10, and the control ball The material ratio is 3.2, the speed of the ball mill is 600r / min, the ball milling time is 36h, the solvent is isopropanol and toluene, after the ball milling is completed, the suspension is taken out, placed in a constant temperature drying oven at 90°C, and then the material is pulverized, passed through 100 The mesh screen is ready for use;

[0067] 2) Put the above-mentioned mixed powder into a desktop tablet press and press to form a green body, then put the green body at 1500°C for...

Embodiment 6

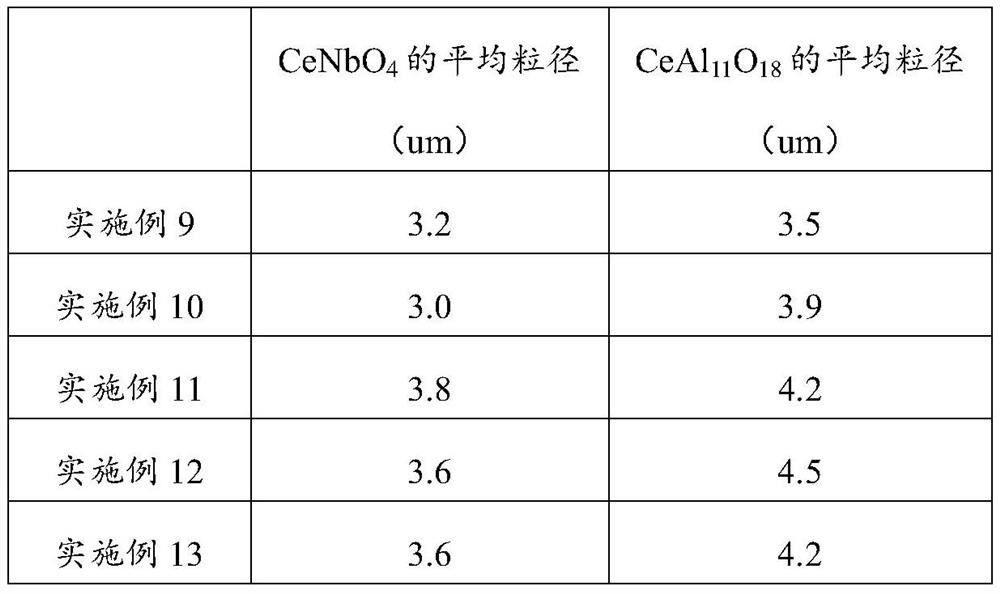

[0073] In embodiment 6, it is the best effect of the above embodiments. The possible reason is that if the content distribution of cerium oxide is low, the CeAl formed 11 o 18 Less content leads to weakened toughening effect. That is, the alumina substrate has the most Good fracture toughness and flexural strength.

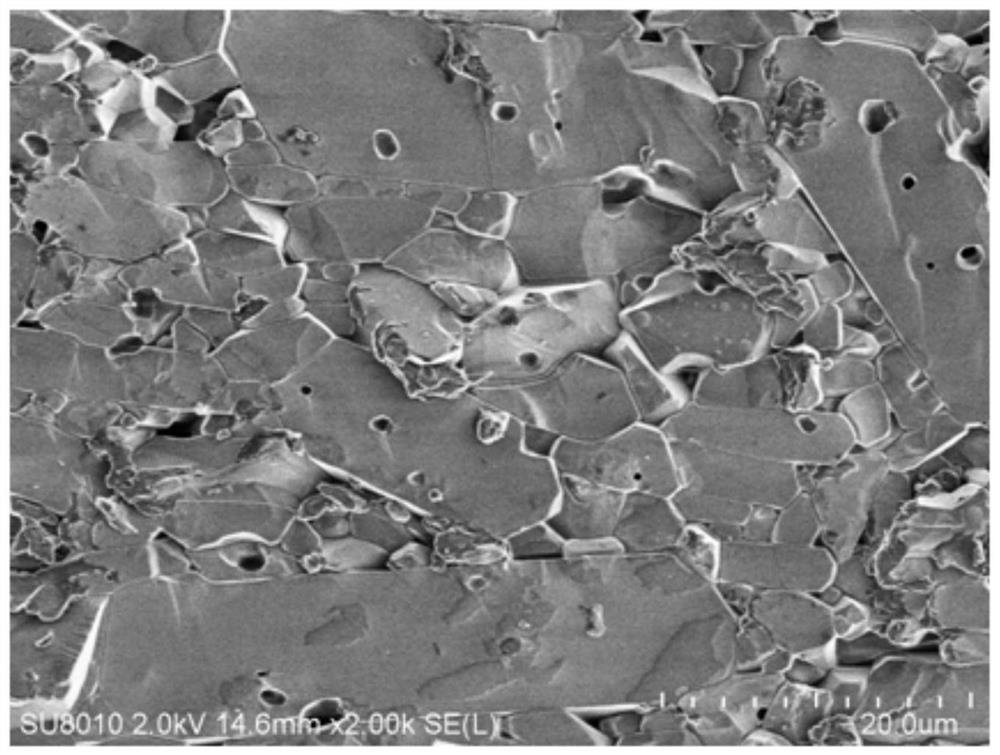

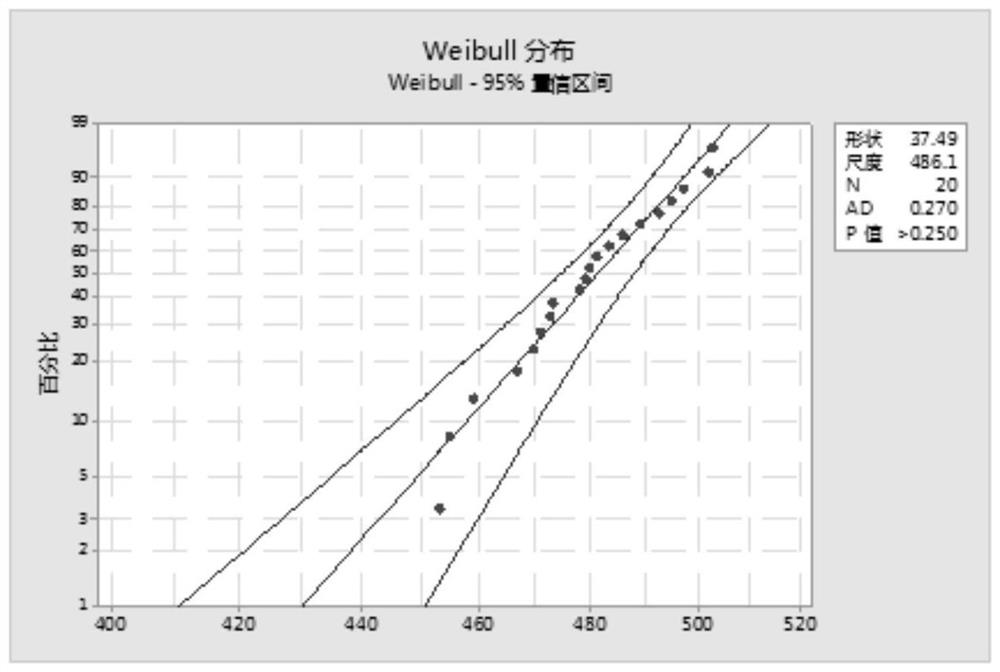

[0074] Simultaneously, carry out scanning electron microscope (SEM) figure observation after the thermal corrosion of columnar aluminum oxide crystal grain in embodiment 6, as figure 1 As shown, it can be seen that the alumina grains mainly present a columnar appearance distribution, and the aspect ratio is greater than 3. It proves that the equiaxed alumina grains in the experiment do grow into columns in situ under the action of additives, so as to achieve the toughening effect. Embodiment 6 is tested according to the Weibull distribution of three-point bending method intensity, as figure 2 As shown, it can be seen that its strength is 486.1MPa through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com