Flame-retardant activated carbon composite sheet

A technology of activated carbon and composite sheets, applied in the direction of inorganic adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of reduced adsorption efficiency, reduced activated carbon content, and high price, and achieve good flexibility and extension The effects of safety, prevention of fire risk, and ease of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

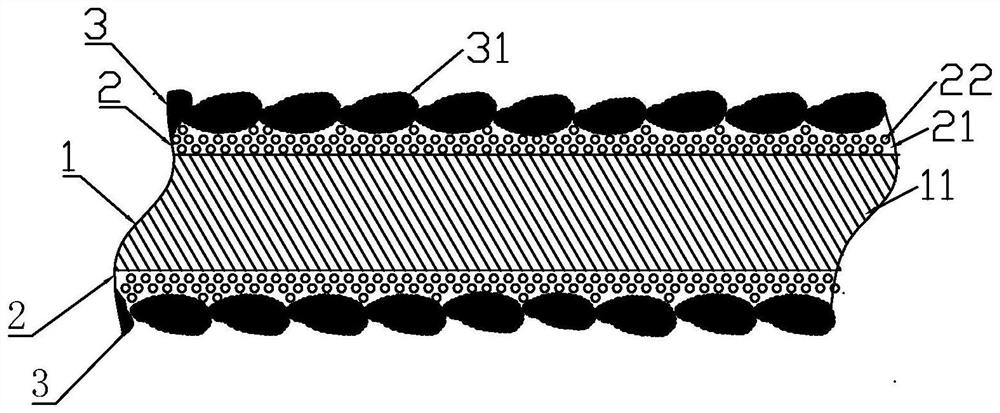

[0029] Embodiment 1: as figure 1 , figure 2 shown, as figure 1 and figure 2 , a fire-retardant activated carbon composite sheet, comprising a metal layer 1, two adhesive layers 2 and two activated carbon layers 3; the metal layer 1 is made of aluminum sheet 11, and the adhesive layer 2 is made of Adhesive 21 constitutes. Each corresponding adhesive layer 2 is correspondingly located on the upper surface and the lower surface of the metal layer 1; that is, the upper surface of the metal layer has an adhesive layer 2, and the lower surface of the metal layer 1 has an adhesive layer 2;

[0030] Each activated carbon layer 3 is adhered through the corresponding adhesive layer 2 and fully covers the corresponding upper surface and lower surface of the metal layer. One side of the activated carbon layer is exposed; flame-retardant particles 22 are distributed in the adhesive layer 2 .

[0031] The aluminum sheet 11 is planar.

[0032] A further preferred embodiment is that t...

Embodiment 2

[0041] Embodiment 2: as figure 1 , image 3 , a fire-retardant activated carbon composite sheet, comprising a metal layer 1, two adhesive layers 2 and two activated carbon layers 3; the metal layer 1 is made of aluminum sheet 11, and the adhesive layer 2 is made of Adhesive 21 constitutes. Each corresponding adhesive layer 2 is located on the upper surface and the lower surface of the metal layer 1 correspondingly;

[0042] Each activated carbon layer 3 is adhered through the corresponding adhesive layer 2 and fully covers the corresponding upper surface and lower surface of the metal layer. One side of the activated carbon layer is exposed; flame-retardant particles 22 are distributed in the adhesive layer 2 .

[0043] The aluminum sheet 11 is corrugated.

[0044] A further preferred embodiment is that the thickness of the aluminum sheet 11 is 50 μm; the rest are the same as the above embodiments.

[0045] A further preferred embodiment is that the activated carbon layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com