Method for preparing carbon-based adsorption material by using sewage advanced treatment coagulated sludge and application of carbon-based adsorption material

A technology of advanced treatment and adsorption materials, applied in water/sewage treatment, pyrolysis treatment of sludge, adsorbed water/sewage treatment, etc. Achieve harmless and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Dry the coagulation sludge of advanced sewage treatment in an electric heating constant temperature blast drying oven at 60°C to constant weight, and use polyaluminum chloride as a flocculant in the advanced treatment process;

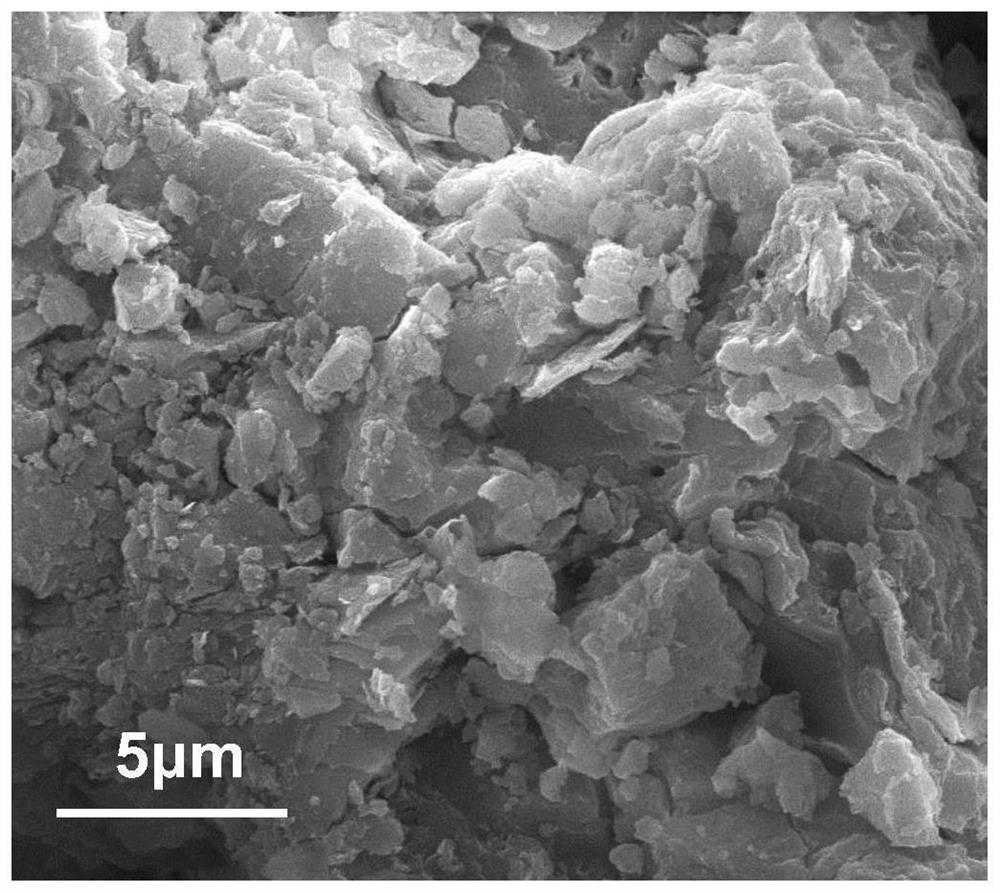

[0035] 2) Grinding the advanced treatment coagulation sludge after step 1) into powder with a grinder and passing through a 100 mesh sieve to obtain powdery sludge with a particle size of about 0.15mm, such as Figure 5 shown;

[0036] 3) Put the sludge powder treated in step 2) into a tube furnace for pyrolysis. During the pyrolysis process, continuously feed carbon dioxide at a rate of 100 mL / min to maintain an oxygen-free environment, and raise the temperature to 400 °C at a rate of 10 °C / min. , keep warm and pyrolyze for 2h;

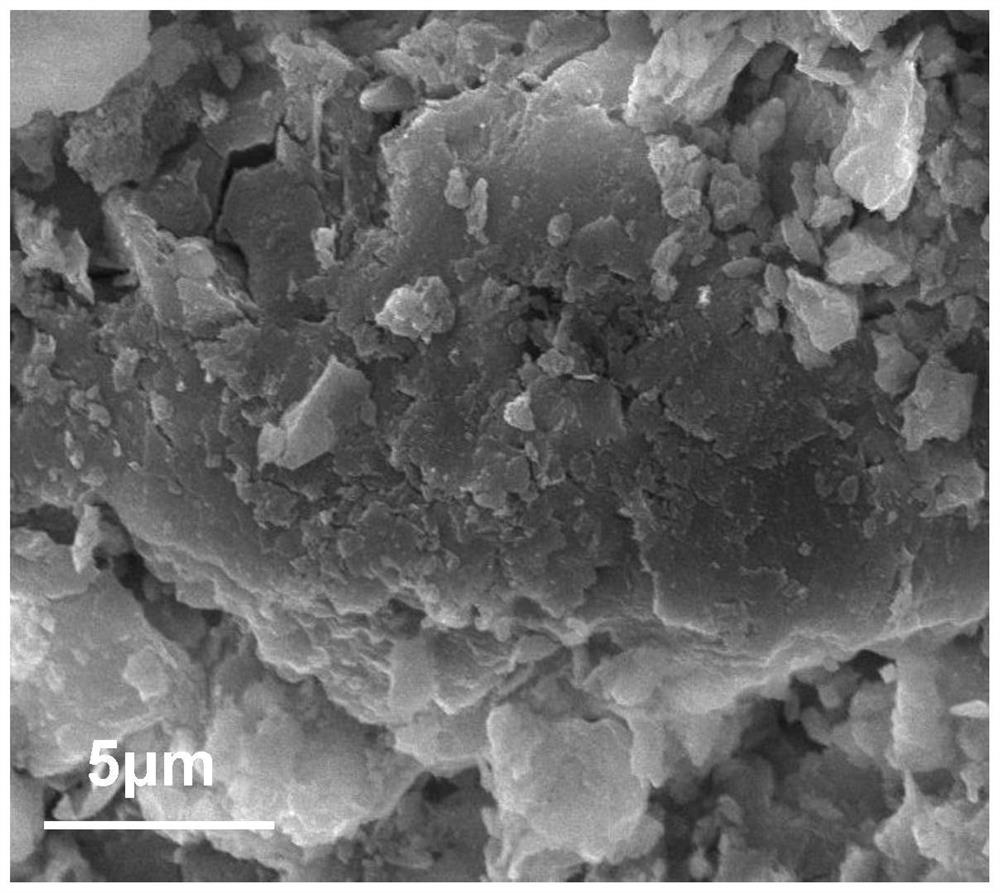

[0037] 4) Cool down to 25±2°C under the condition of continuously feeding carbon dioxide to obtain coagulated sludge carbon-based products for advanced sewage treatment, such as Figure 4 shown.

[0038] Carry ou...

Embodiment 2

[0061] The difference between this example and Example 1 is that the constant pyrolysis temperature is 700° C., and the rest of the operation steps are the same as those of Example 1.

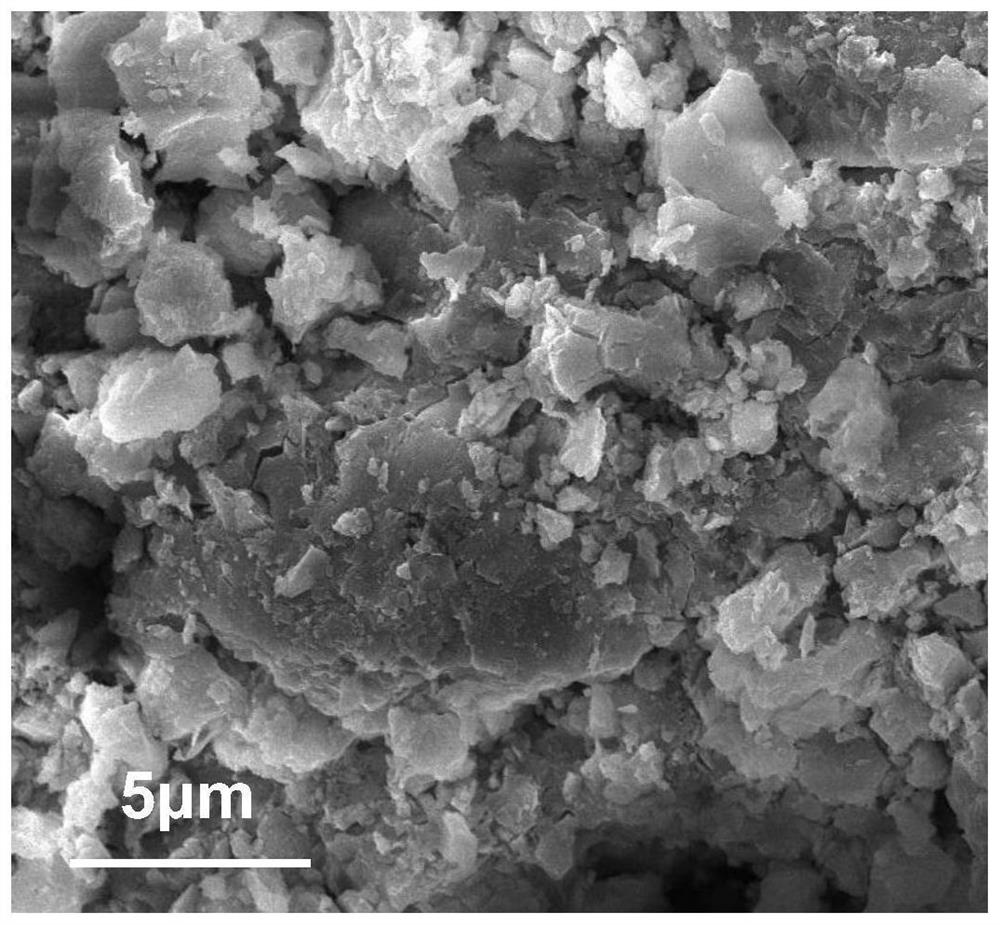

[0062] The advanced treatment sludge charcoal-based product obtained in this embodiment has no ecological toxicity risk, and the SEM photo is as follows figure 2 As shown, the product has a rough and irregular surface, and the BET specific surface area is 135.09m 2 g -1 , the total pore volume is 0.191cm 3 g -1 . The static adsorption capacity of this product for phosphorus is 12mg-P g -1 , the static adsorption capacity of lead, a representative heavy metal substance, is 34 mg g -1 , the adsorption capacity of methylene blue is 15 mg g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com