Pig farm waste water processing technology

A pig farm wastewater and treatment process technology, applied in animal husbandry wastewater treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of high cost of subsequent sludge treatment, large amount of sludge produced, complex facilities, etc. , to achieve the effect of simple facilities, reduced processing costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

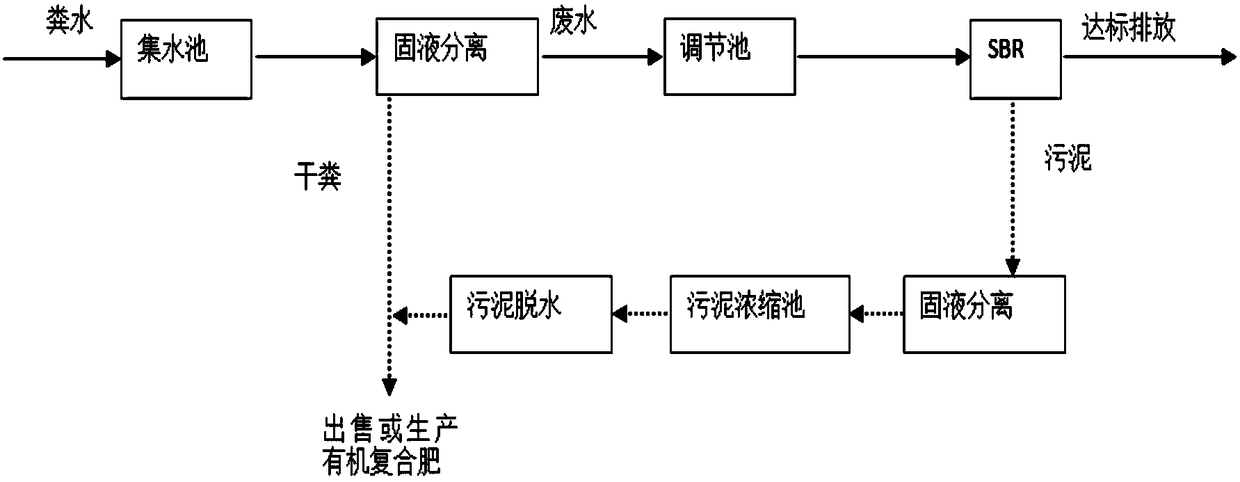

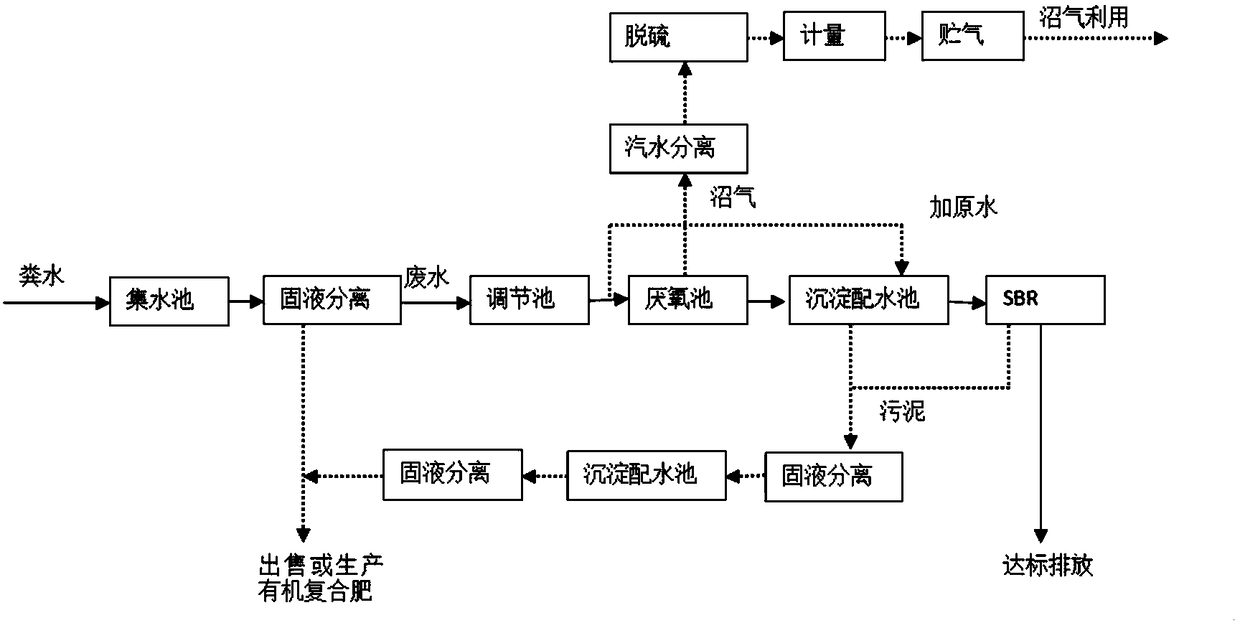

Method used

Image

Examples

Embodiment 1

[0033] A pig farm wastewater treatment process, comprising the following steps:

[0034] Step A1, carrying out a solid-liquid separation of pig farm waste water through a sump, and the solid waste I obtained is used as a raw material for organic compound fertilizer; wherein, the hydraulic retention time of the sump is 0.2h;

[0035] In step A2, the liquid waste I obtained from the primary solid-liquid separation is subjected to a second solid-liquid separation through a biomultiplication biochemical reaction tank, and the solid waste II obtained in the second solid-liquid separation is subjected to calcium salt enhanced flocculation precipitation through a flocculation sedimentation tank, and the obtained precipitate is used for It is used for the recycling of phosphate fertilizer; the matrix filler of the flocculation sedimentation tank is set alternately with modified seaweed soft layer and modified coal gangue layer three times, a total of six layers; among them, compound ba...

Embodiment 2

[0041] A pig farm wastewater treatment process, comprising the following steps:

[0042] Step A1, carrying out a solid-liquid separation of pig farm waste water through a sump, and the solid waste I as a raw material for organic compound fertilizer; wherein, the hydraulic retention time of the sump is 0.3h;

[0043] In step A2, the liquid waste I obtained from the primary solid-liquid separation is subjected to a second solid-liquid separation through a biomultiplication biochemical reaction tank, and the solid waste II obtained in the second solid-liquid separation is subjected to calcium salt enhanced flocculation precipitation through a flocculation sedimentation tank, and the obtained precipitate is used for It is used for the recycling of phosphate fertilizer; the matrix filler of the flocculation sedimentation tank is set alternately with modified seaweed soft layer and modified coal gangue layer three times, a total of six layers; among them, compound bacteria are added ...

Embodiment 3

[0050] A pig farm wastewater treatment process, comprising the following steps:

[0051] Step A1, carrying out a solid-liquid separation of pig farm waste water through a sump, and the solid waste I obtained as a raw material for organic compound fertilizer; wherein, the hydraulic retention time of the sump is 0.25h;

[0052] In step A2, the liquid waste I obtained from the primary solid-liquid separation is subjected to a second solid-liquid separation through a biomultiplication biochemical reaction tank, and the solid waste II obtained in the second solid-liquid separation is subjected to calcium salt enhanced flocculation precipitation through a flocculation sedimentation tank, and the obtained precipitate is used for It is used for the recycling of phosphate fertilizer; the matrix filler of the flocculation sedimentation tank is set alternately with modified seaweed soft layer and modified coal gangue layer three times, a total of six layers; among them, compound bacteria ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com